|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

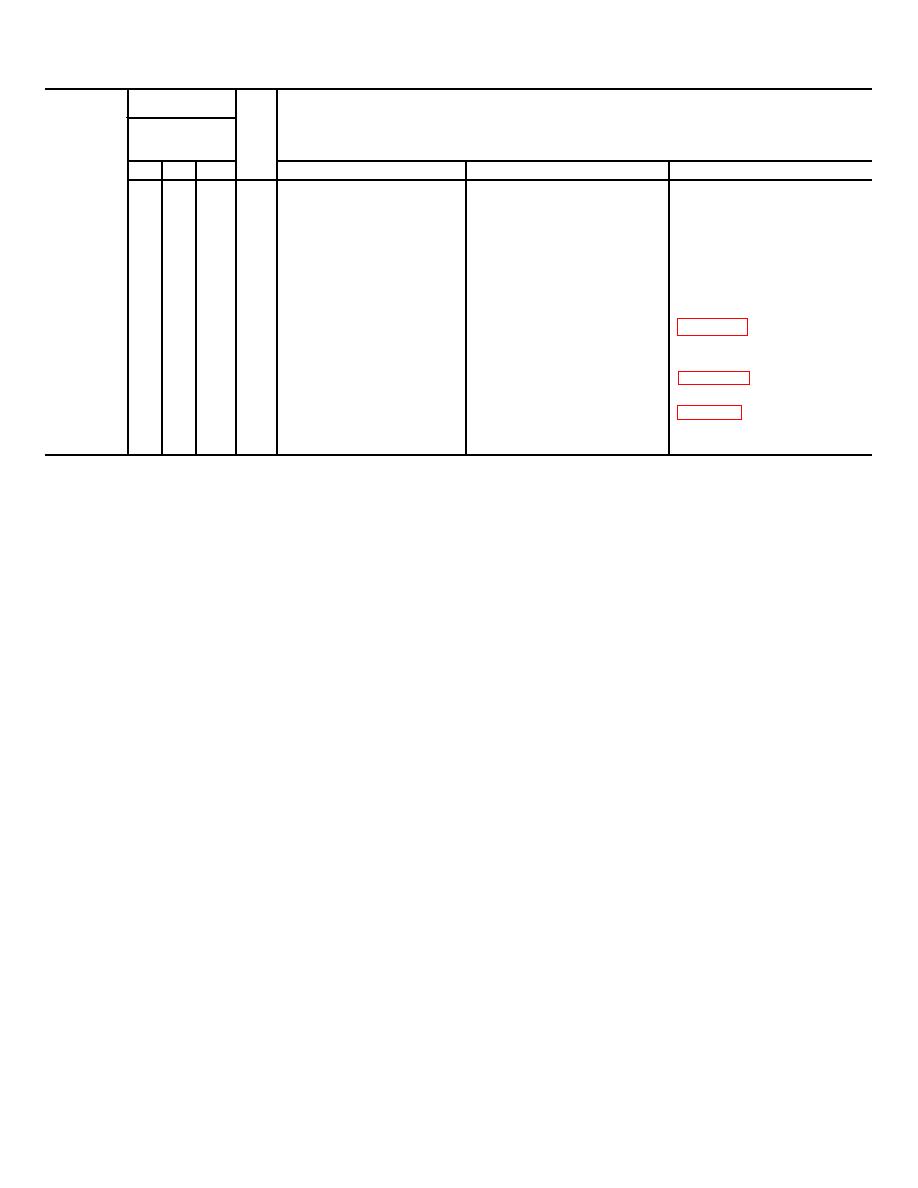

Table 3-1. Preventive Maintenance Checks and Services - Continued

Operator

B-Before operation

A-After operation

Item

Daily

W

D-During operation

W-Weekly

Number

B

D

A

Item to be inspected

Procedure

Reference

4

X

Hydraulic Oil Reservoir

Check fluid level. Add fluid

Fill to cover bottom of

if needed. Check for a dirty

strainer with mast down.

breather cap strainer or

Refer other maintenance to

filter screen.

organizational personnel.

5

X

Lights

Check operation.

Refer maintenance to

organizational personnel.

6

X

Horn

Check operation.

Refer maintenance to

organizational personnel.

7

X

Brakes

Check for strong pressure

when brake pedal is pushed

8

X

Lift and Tilt Control

Check for proper lift and tilt

operation.

Check for loose mounting

9

X

Controls and Instruments

and damage. With unit

operating, check for proper

operation.

Section IV. TROUBLESHOOTING

3-5. Troubleshooting

Troubleshooting is performed at organization and higher

levels.

Section V. MAINTENANCE OF ELECTRICAL SYSTEM

light switch and check that headlight and tail light

3-6. General

operate.

The operator is responsible for checking the proper

c. Stoplight Switch, and Stoplight. Depress

operation of the hour meter, light switch, emergency stop

brake pedal and check that stoplight operates.

switch, stoplight switch, headlight, stop and tail light. and

d. Emergency Stop Switch. With no load and

the horn assembly. Any defect in operation must be

the truck moving slowly, push the emergency stop

reported to organizational personnel.

switch. The truck should immediately stop and power

a. Hour Meter. During operation of the truck,

removed from the truck drive.

check that hour meter is recording elapsed operating

e. Horn Assembly. Press horn button and listen

time.

for horn.

b. Light Switch, Headlight and Tail Light. Pull

Section VI. MAINTENANCE OF BRAKE SYSTEM

organizational personnel.

3-7. General

3-9. Master Cylinder

The operator is responsible for testing the brake

Remove cap and check fluid level. If needed, fill with

assembly and servicing the master cylinder.

brake fluid to within 1/4 inch of top. Replace cap. Refer

3-8. Brake Assembly

other maintenance to organizational personnel.

Push the brake pedal to test for strong hydraulic

pressure.

Refer any needed maintenance to

3-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |