|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

terminal. Press horn button and note the voltage. If the

4-42. Horn

voltage is between 0 and 10.7 volts, replace the horn.

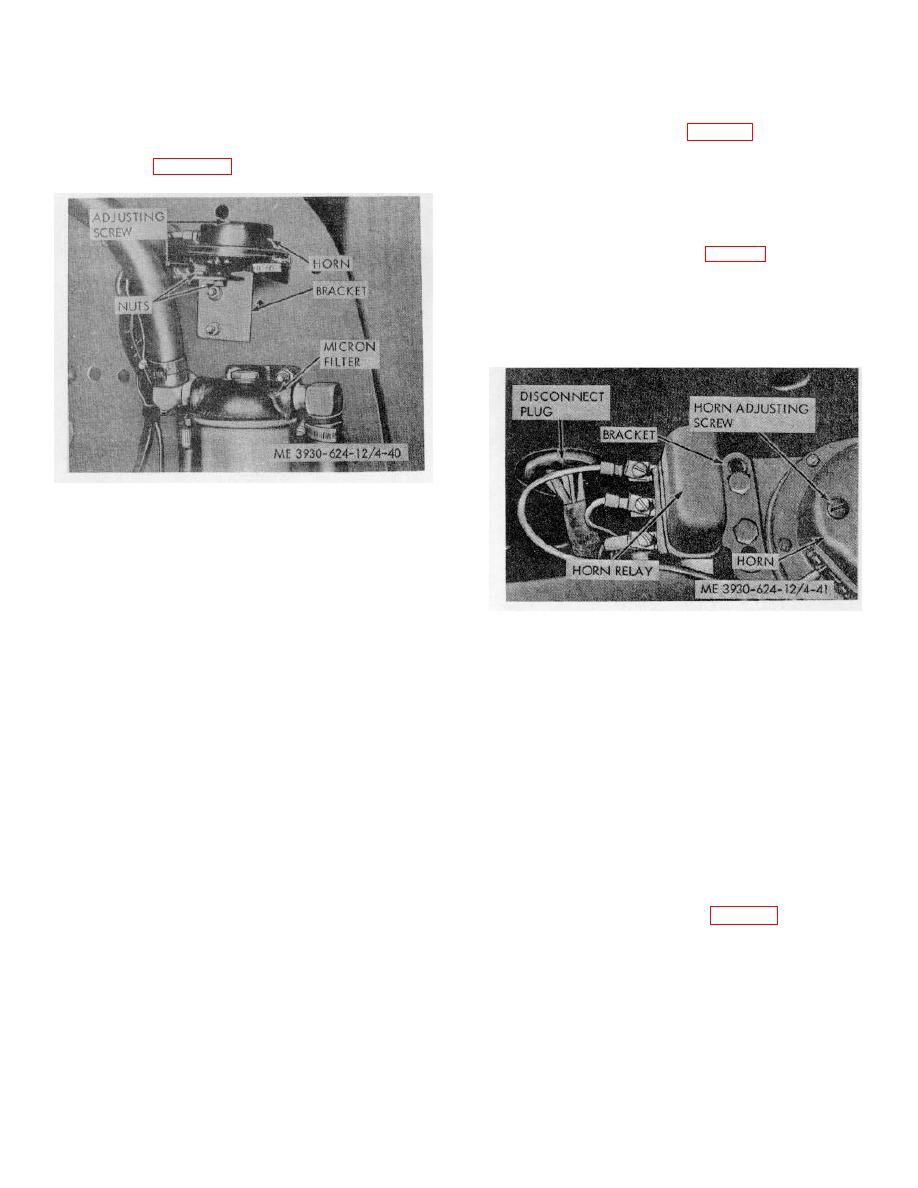

a. Removal.

(2) If the horn signal is weak and the voltage

(1) Tag and disconnect electrical leads to the

is normal at the horn terminal, check the volume

horn.

adjusting screw in horn cover (fig. 4-40). Turn the screw

(2) Remove the two nuts and lockwashers

clockwise to increase the volume or counterclockwise to

securing the horn to the mounting bracket. Remove the

decrease the volume.

horn. Refer to figure 4-40.

4-43. Horn Relay

a. Removal. Remove two nuts, washers, and

capscrews securing the horn relay to the bracket. Tag

and disconnect wiring. (Refer to fig. 4-41.)

b. Cleaning and Inspection.

(1) Clean the relay housing with a cloth

dampened with a solvent.

(2) Check the relay assembly for corrosion,

dents, cracks, or other damage. Replace if necessary.

Figure 4-40. Horn mounting and adjusting screw.

b. Cleaning and Inspection.

(1) Clean the horn with a cloth dampened

with a solvent.

(2) Check the horn for cracks, corrosion, and

other damage. Replace the horn if damaged.

c. Installation. Install in the reverse order of

Figure 4-41. Horn relay.

removal.

d. Adjustment.

(1) If the horn produces a weak signal,

c. Installation. To install horn relay, reverse the

connect a voltmeter from the ground to the horn

removal procedure.

Section XII. MAINTENANCE OF THE TRANSMISSION

heat exchanger and back to the transmission.

4-44. General

a. The transmission is mounted between the

engine and the drive axle assembly, immediately below

4-45. Transmission Oil Lines and Filter

the operator's seat. The transmission is connected to

a. Filter Service.

the torque converter on one end, and to the universal

(1) To change the transmission fluid, run the

joint on the other. It is a constant mesh, full reversing,

truck to warm the fluid to operating temperature. Drain

power shift type. The forward and reverse directions are

the fluid by removing the transmission drain plug from

selected by positioning the power shift lever mounted on

the bottom of the transmission (fig. 4-42). Drain fluid

the steering column. The power shift lever is connected

from torque converter by removing the floor plate, and

by a mechanical linkage to the selector valve on the

the inspection cover from the torque converter housing.

transmission.

Remove the drain plug. Rotate the torque converter

b. The transmission fluid is cooled by a heat

180. The fluid in the converter will flow into the

exchanger located in the lower part of the radiator. The

transmission, and will drain from the transmission drain

fluid is pumped from the transmission, through the

plug.

4-37

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |