|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(5) Pull the starting motor out of the flywheel

4-35. Starting Motor

housing until the drive end clears the flywheel housing

a. Testing.

and tilt the commutator end up to remove the unit from

(1) Use a battery known to be in good con

the truck.

dition and an accurate voltmeter. Connect the positive

c. Cleaning and Inspecting.

lead of the voltmeter to the positive terminal of the

(1) Clean the exterior of the starting motor

battery, and the negative lead to the negative terminal

with a cloth dampened with a cleaning solvent; dry

of the battery. Record the voltage reading.

thoroughly. Take care to prevent the solvent from

(2) Pull the high tension lead from the ignition

entering the starting motor.

coil to prevent the engine starting during the starting

(2) Inspect the starting motor for cracks, bent

motor test.

or damaged terminals, signs of overheating, damaged

(3) Connect the positive lead of the voltmeter

pinion teeth, and other damage. Check the armature

to the ground and the negative lead of the voltmeter to

shaft for free rotation. Replace the starter if damaged.

the starter button terminal. Turn the ignition switch on

d. Installation.

and push the starter button and read the voltmeter.

(1) Install the starting motor using the direct

(4) Compare the voltmeter reading with the

reversal of the removal procedure.

previously recorded voltmeter reading. If the voltage

(2) Cheek the operation of the starting motor.

drop is less than 4 volts, or if the second reading is less

Make sure it cranks the engine as required.

than 8 volts, the starting motor is probably faulty.

4-36. Ignition Distributor

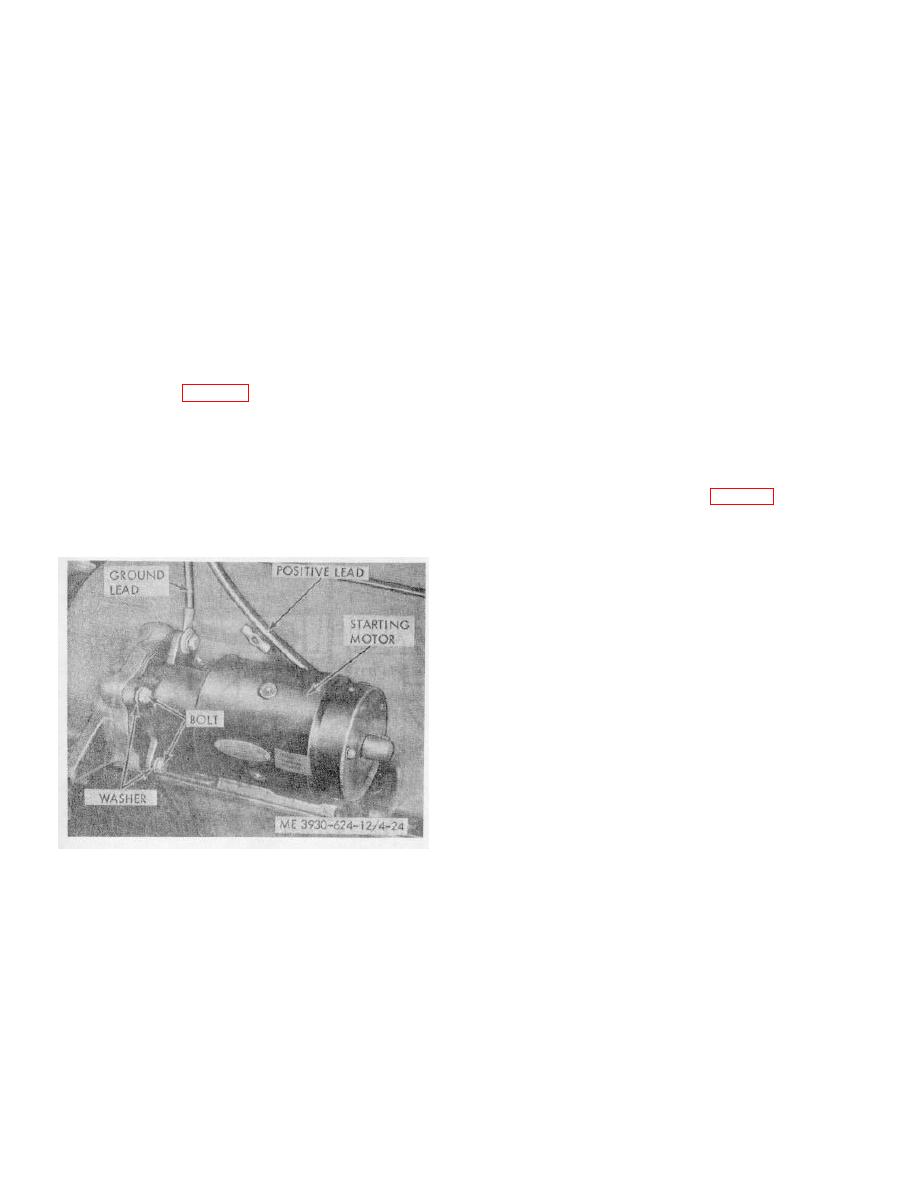

b. Removal. (fig. 4-24).

a. Distributor Points, Repair and Replacement.

(1) Lift the operator's seat and remove the

side panels.

(1) Remove the distributor cap by loosening

(2) Disconnect the negative battery cable

the retaining screws and remove the rotor and the dust

from the battery.

shield from the distributor housing.

(3) Tag and disconnect all electrical leads to

(2) Remove the nut and washer from the

the starting motor.

inner end of the primary terminal (fig. 4-25).

(4) Remove the mounting bolts securing the

starting motor to the flywheel housing.

Figure 4-24. Starting motor.

4-28

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |