|

|||

|

|

|||

|

Page Title:

Section XI. MAINTENANCE OF THE ELECTRICAL SYSTEM |

|

||

| ||||||||||

|

|

(9) Install the hydraulic pump by direct

b. Replacement.

reversal of the removal procedure. Install the rear grille.

(1) Remove the rear grille from the

(10) Install the side panels and the lower seat.

counterweight.

(2) Raise the operator's seat and remove the

side panels.

(3) Remove split flange on the suction tube

on the hydraulic pump; remove the pump as shown in

(4) Remove the four capscrews and washers

securing the pump to the engine block. Slide the pump

away from the engine block to provide enough

clearance to install the fan belt.

(5) Loosen the alternator to relieve the

tension on the fan belt. Slide the belt from the

crankshaft pulley.

(6) Slide the belt off the alternator pulley,

then off fan pulley and over the fan.

Caution: Care should be not taken. To

bend the radiator fins.

(7) Install a new belt over the fan and around

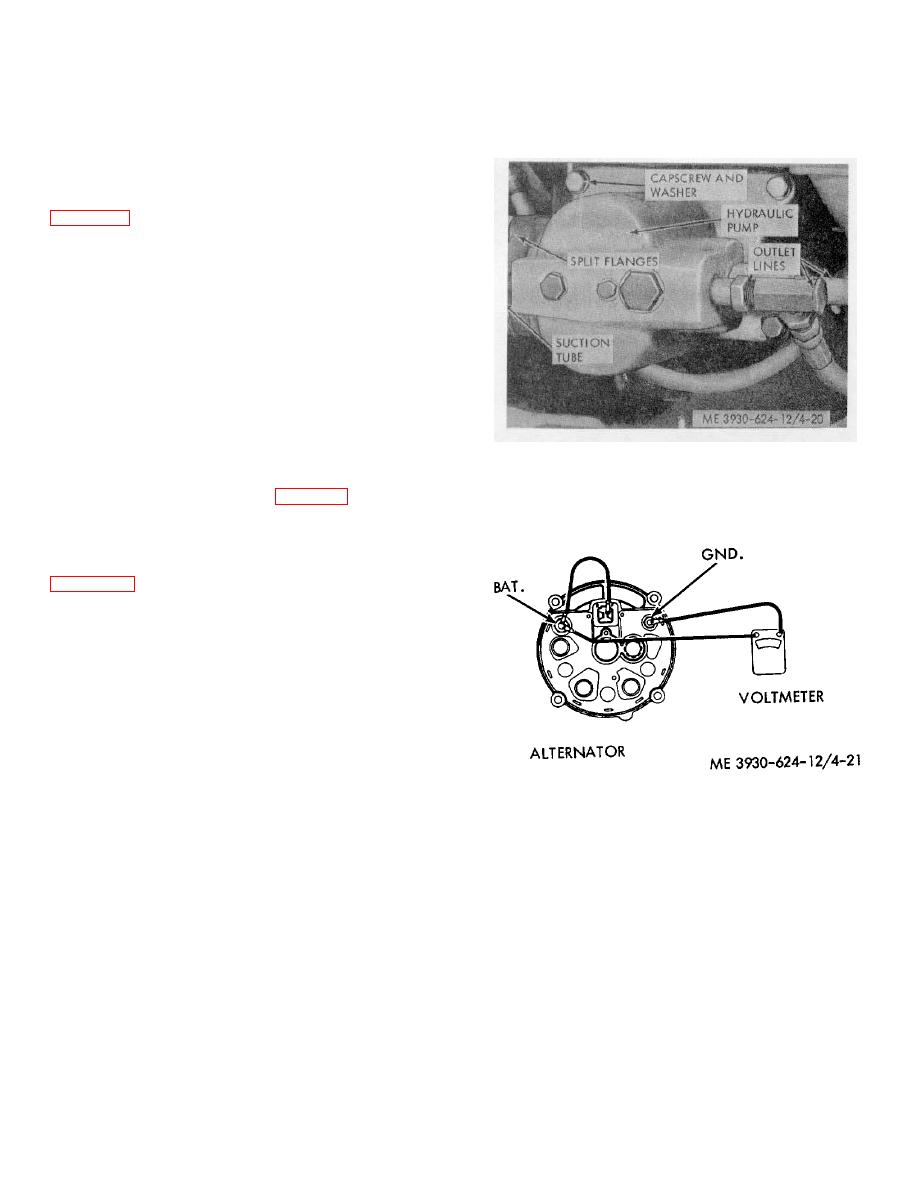

Figure 4-20. Hydraulic pump removal.

the fan pulley, alternator pulley and crankshaft pulley.

(8) Adjust the fan belt (para 4-31).

Section XI. MAINTENANCE OF THE ELECTRICAL SYSTEM

4-32. General

The electrical wiring diagram for the truck is shown is

distributor, alternator, ignition coil, spark plugs, starter

motor, solenoid, current and voltage regulator, wiring,

and accessories.

Electrical gages and horn are

protected by fuses in the circuit. Fuses are located on

the underside of the instrument panel. The instrument

panel wiring terminates in a multiple male connector.

The engine, accessories, and chassis wiring terminates

in a multiple female connector to provide a quick

disconnect for ease of service.

4-33. Alternator

a. Testing the Alternator.

Figure 4-21. Checking alternator output.

(1) Disconnect the four terminal connector

from the regulator.

b. Removal.

(2) Disconnect the two-terminal connector

Warning: Always disconnect the

from the alternator F and R terminals.

battery cable from the negative

(3) Connect a jumper wire from the BAT

terminal to the F terminal on the alternator.

battery post before making electrical

(4) Connect a voltmeter from the alternator

repairs on the truck.

BAT terminal to the GRD terminal.

(1) Tag the electrical leads to alternator;

(5) Start the engine and turn on the lights.

disconnect the leads.

Run the engine at 1500 RPM or above and note whether

(2) Loosen the fan belt and remove the

voltage exceeds 12.5 volts. If voltage exceeds 12.5 in a

alternator.

few minutes, the alternator output is operating normally.

c. Installation.

Stop the engine, turn off lights and connect wiring.

(1) Install the alternator by reversing the

removal procedure.

4-25

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |