|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(8) Install any other

parts

which

were

(3) Idle fuel adjustment.

removed for carburetor repairs.

(a) Turn the idle adjusting jet (4)

clockwise to obtain a lean mixture or turn

counterclockwise to obtain a rich mixture.

4-20.

Fuel Pump

(b) Adjust the idle screw until the

engine runs smoothly.

a. Testing.

b. Removal.

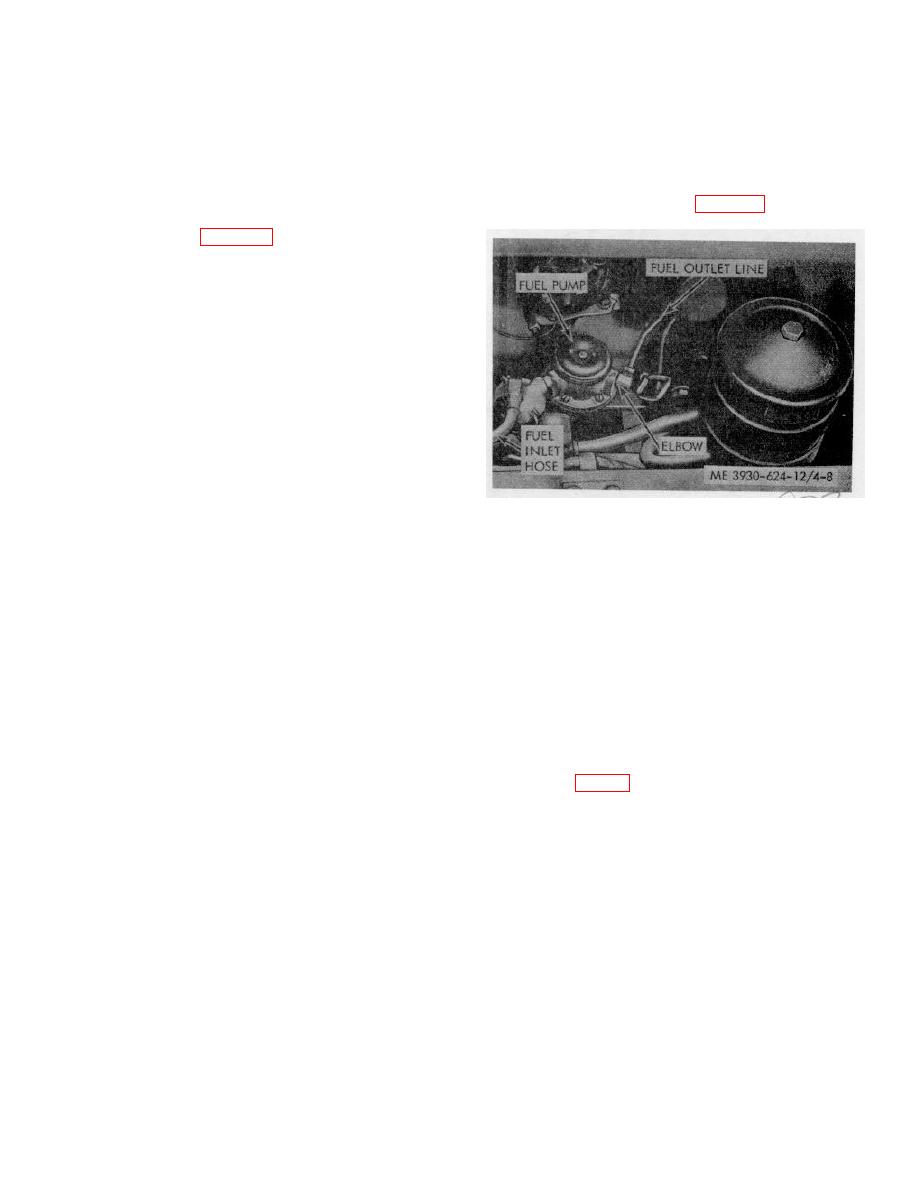

(1) Disconnect the fuel outlet line at the fuel

(1) Lift the operator's seat, and remove the

pump. Install a 0 to 10 psi pressure gage to the outlet

side panel from the left side of the truck.

port of the fuel pump. Refer to figure 4-8.

(2) Remove the air cleaner and air cleaner

hose from carburetor (para 4-25).

(3) Disconnect the fuel inlet line (6).

(4) Remove the accelerator rod (1) and

governor control rod (5). Note the position of the throttle

lever and governor lever before removing the control

rods.

Note. Do not change the lengths' of rods.

(5) Disconnect the choke control cable (11).

(6) Remove the two nuts and lockwashers (3)

attaching the carburetor to the intake manifold, and

remove the carburetor.

c. Installation.

(1) Install a new gasket over the studs in the

carburetor mounting flange.

Figure 4-8. Fuel pump.

(2) Install the carburetor on the intake

manifold and secure with two nuts and lockwashers (3).

(2) Run the engine at 1800 rpm on the fuel

(3) Position the choke control cable (11) in

remaining in the carburetor.

the choke bracket (10) and install the choke in the

(3) Note the pressure on the pressure gage.

swivel connection (9).

The pressure should be between 21/2 and 33/4 psi.

(4) Install the governor control rod (5) on the

(4) If the pressure does not fall within these

governor throttle lever (7).

limits, replace the pump.

(5) Install the accelerator rod (1). If the rod

b. Inspection.

length has been altered, adjust the ball joint so the

(1) Inspect the copper fuel line for

accelerator pedal will fully open and close the throttle

restrictions. Blow out the compressed air or replace if

plate.

damaged.

(6) Connect the fuel inlet line (6) and install

(2) Inspect the flexible line for breaks or a

the air cleaner by reversing the removal procedure.

frayed condition. Replace if necessary.

(7) Start engine and run until normal

c. Removal.

operating temperature is reached. Refer to step a.for

(1) Close the shut-off valve at the bottom of

adjustment.

the fuel tank (fig. 4-9).

4-15

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |