|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-623-12

2. Wiring and Terminals. Check wiring for cracked

and frayed insulation.

Reposition wiring whose

insulation is being damaged by rubbing or contact with

5-34. CHARGING SYSTEM MAINTENANCE.

surrounding objects.

Tape or replace damaged

electrical leads. Protect wiring from being saturated with

1. Battery. Daily, check fluid level of battery. If

lubricants. Keep terminals clean and free of corrosion.

necessary, add distilled water until water reaches

Check ground cable of battery frequently for corrosion

required level to cover plates. Keep battery clean. If

and deterioration.

necessary, flush corrosion from top with solution of

baking soda and water. This will neutralize battery

3. Regulator. Test regulator settings periodically with

acids.

Make sure battery cables are securely

good test equipment.

In case of battery over or

connected. In subfreezing temperatures, run engine for

undercharge, test and if necessary adjust or replace

at least 30 minutes after adding water to battery to

regulator before replacing battery.

assure that water will mix with acid and will not freeze. If

condition of battery is in doubt, check each cell with a

4. Alternator Drive Belt Tension. Maintain alternator

hydrometer to check if individual cells are faulty.

drive belt tension so that drive belt can be deflected one-

Recharge battery after properly filling with distilled water

half inch by finger pressure at midpoint between drive

and recheck with hydrometer after charging. If cell or

and driven pulleys. To adjust tension, loosen cap screw

cells continue to show low readings, replace battery.

that holds adjusting strap to alternator (see figure 5-1)

and loosen bolts that hold alternator to mounting

bracket. To tighten, use bar to pry alternator away from

CAUTION

engine to achieve correct tension; then tighten adjusting

strap cap screw. Tighten mounting bolts.

This truck uses an alternator instead

of a dc generator.

Special

precautions must be taken to prevent

5-35. ALTERNATOR.

reversal of polarity when changing,

1. Alternator Precautions. Since this truck is provided

charging, or boosting battery. Refer

with an alternator some special maintenance

to paragraph 5-35 for special

precautions are necessary. Note that alternator and

instructions.

regulator circuits have negative ground. Take special

care that following procedures are used. Failure to

follow these procedures will result in burned out diodes

and/or alternator windings.

a. When installing battery, always make absolutely

sure negative terminal of battery is grounded.

b. When connecting booster battery, make certain

to connect negative battery terminals together and

positive battery terminals together.

c. When connecting charger to battery, connect

charger positive lead to positive battery terminal and

charger negative lead to negative battery terminal.

d. Never operate alternator on open circuit. Make

sure all connections in circuit are secure.

e. Do not short across or ground any alternator

terminals or regulator terminals.

2. Alternator Removal, Installation, and Test.

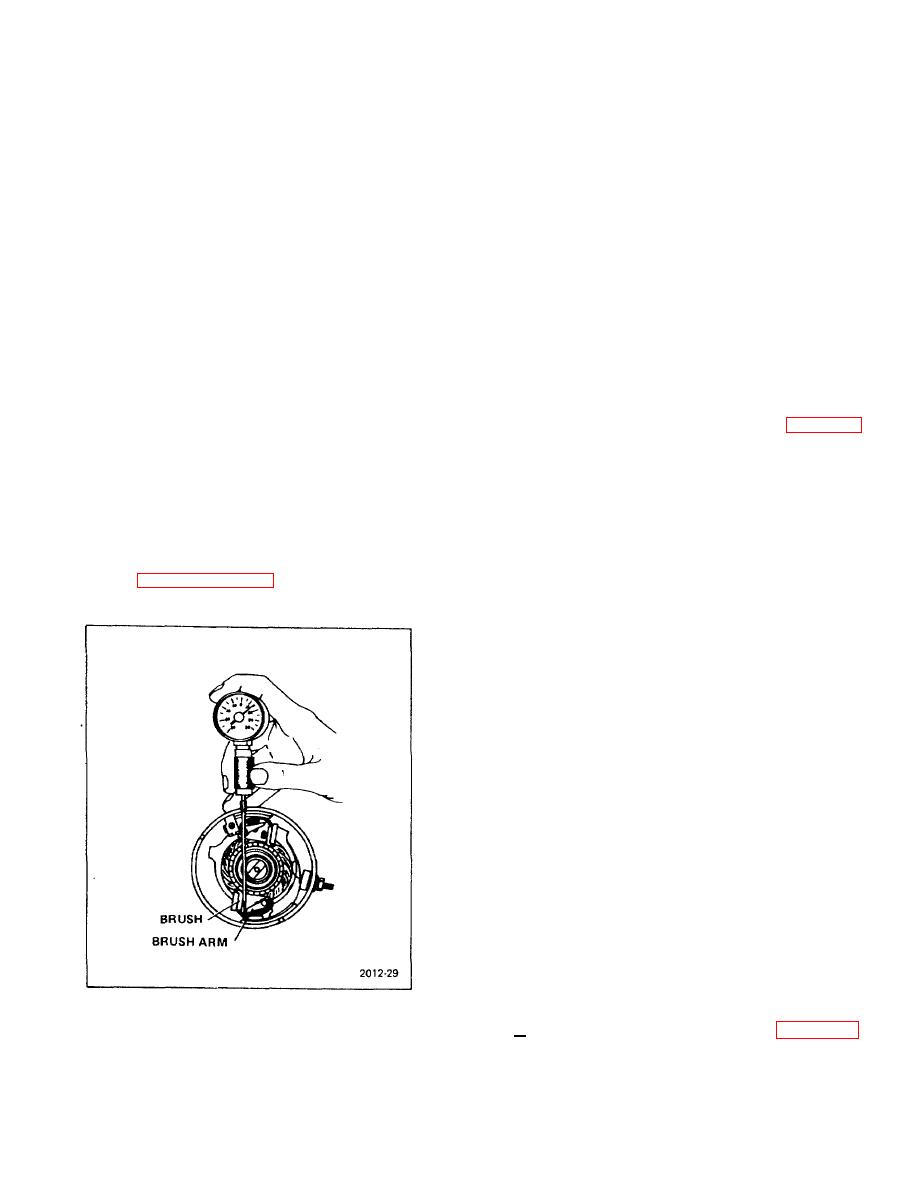

Figure 5-8. Measuring Brush Spring Tension

a. Remove alternator from truck (para 6-51).

Clean alternator with cloth dampened with cleaning

solvent. Dry thoroughly. Do not allow solvent to enter

alternator.

5-8/9/10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |