|

|||

|

|

|||

|

Page Title:

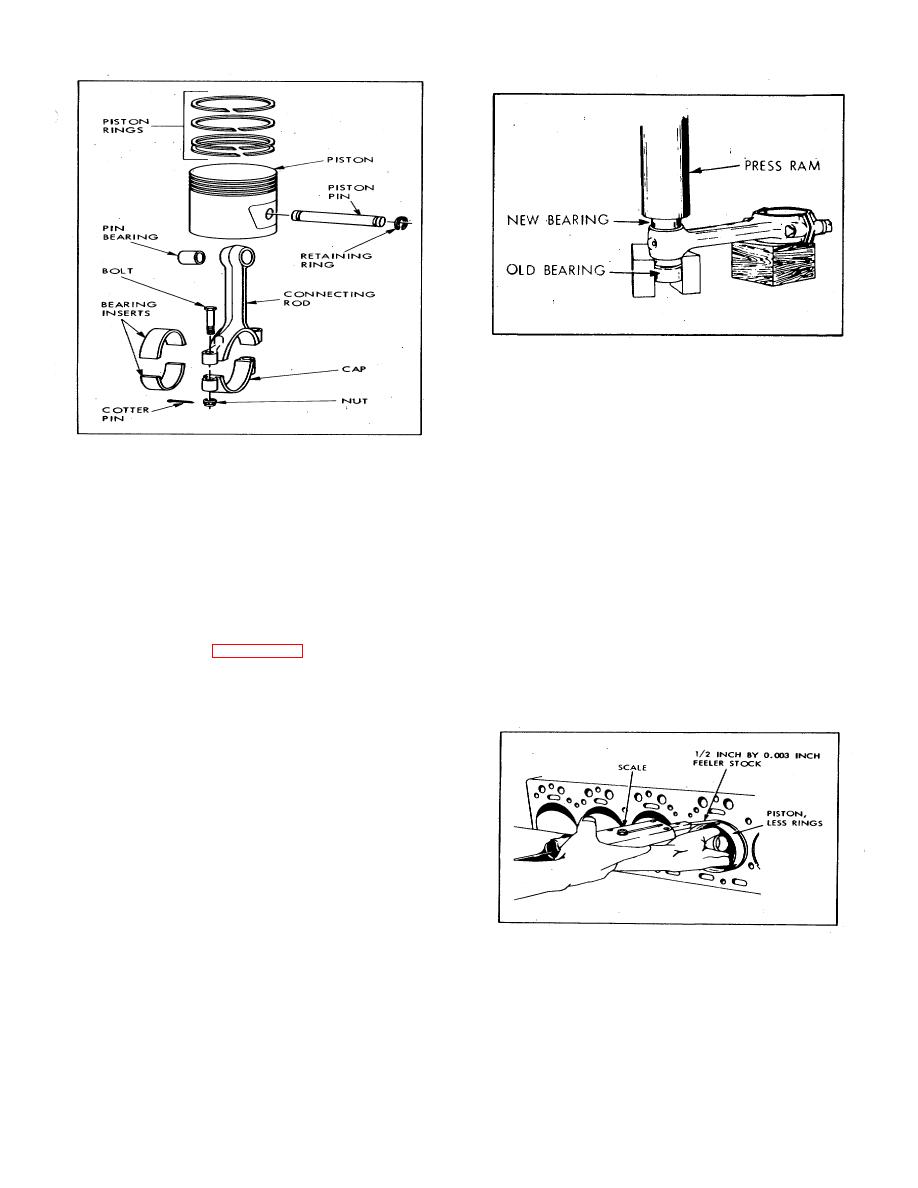

Figure 6-33. Piston and Rod Assembly |

|

||

| ||||||||||

|

|

Figure 6-34. Pressing in New Piston Pin Bearings

spring scale into the end of the feeler ribbon and pull the

feeler ribbon from the cylinder. If the fit is correct, the

scale should register 5 to 10 pounds pull.

e. Piston pin fit. Check the fit of the piston pin in

Figure 6-33. Piston and Rod Assembly

the

piston and the connecting rod. The piston pin should

c. Cleaning.

be a thumb push fit ii the piston pin bearing and a palm

(1) Soak pistons in SD and remove carbon

push fit in the piston bosses. If the piston pins or

from the tops and from ring grooves of the pistons.

bearings are worn, they must be replaced with standard

(2) Using a drill or probe of the proper size,

size pins and bearings. If the piston bosses are worn,

clean carbon from the oil return holes in the ring grooves.

the piston must be replaced.

(3) Clean the oil groove passages in the

f. Piston ring installation.

connecting rods and caps.

(1) Always install new piston rings during an

d. Piston fit. Fit the pistons clean and dry. To fit

overhaul of the engine. Replacement rings are available

the pistons to the cylinder bore properly, use a spring

in standard size, in 0.020 inch oversize, and in 0.040 inch

scale and a feeler ribbon 1/2 inch wide, 10 inches long,

oversize.

and 0.003 inch thick (Figure 6-35). Insert the feeler

(2) To determine whether the ring has the

ribbon full length into the cylinder bore, about halfway

proper end gap, place it in the cylinder, pushing it about

down. Hook the

halfway down in the cylinder bore. With the ring square

with the cylinder

Figure 6-35. Measuring Piston Fit in Cylinder

107

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |