|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

c. Reassembly.

(9) Put in drain plugs.

(1) Insert key in shaft, press pump gear on shaft,

install snap ring, then press shaft back so that snap ring

(10) Reinstall starting motor and cables.

seats in gear.

(11) Reinstall bayonet gauge assembly.

(2) Assemble shaft in body, install thrust washer,

insert Woodruff key and press on drive gear. This shaft

(12) Refill with oil to correct level.

must have 0.0015 inch to 0.003 inch end thrust.

(3) Insert drive gear pin and peen over ends of

6-58. OIL PUMP.

pin. (If new shaft is used, it must be drilled for pin. Use

holes in gear as guide.)

a. Removal. Remove oil pan (paragraph 6-57).

Remove three mounting screws and' washers securing

(4) Insert idler gear and shaft.

oil pump to crankcase and remove oil pump and gasket.

(5) Rotate shaft and check for tight places.

b. Disassembly.

Shaft should rotate freely. If pump shaft does not rotate

easily, disassemble and check for dirt or chips in gear

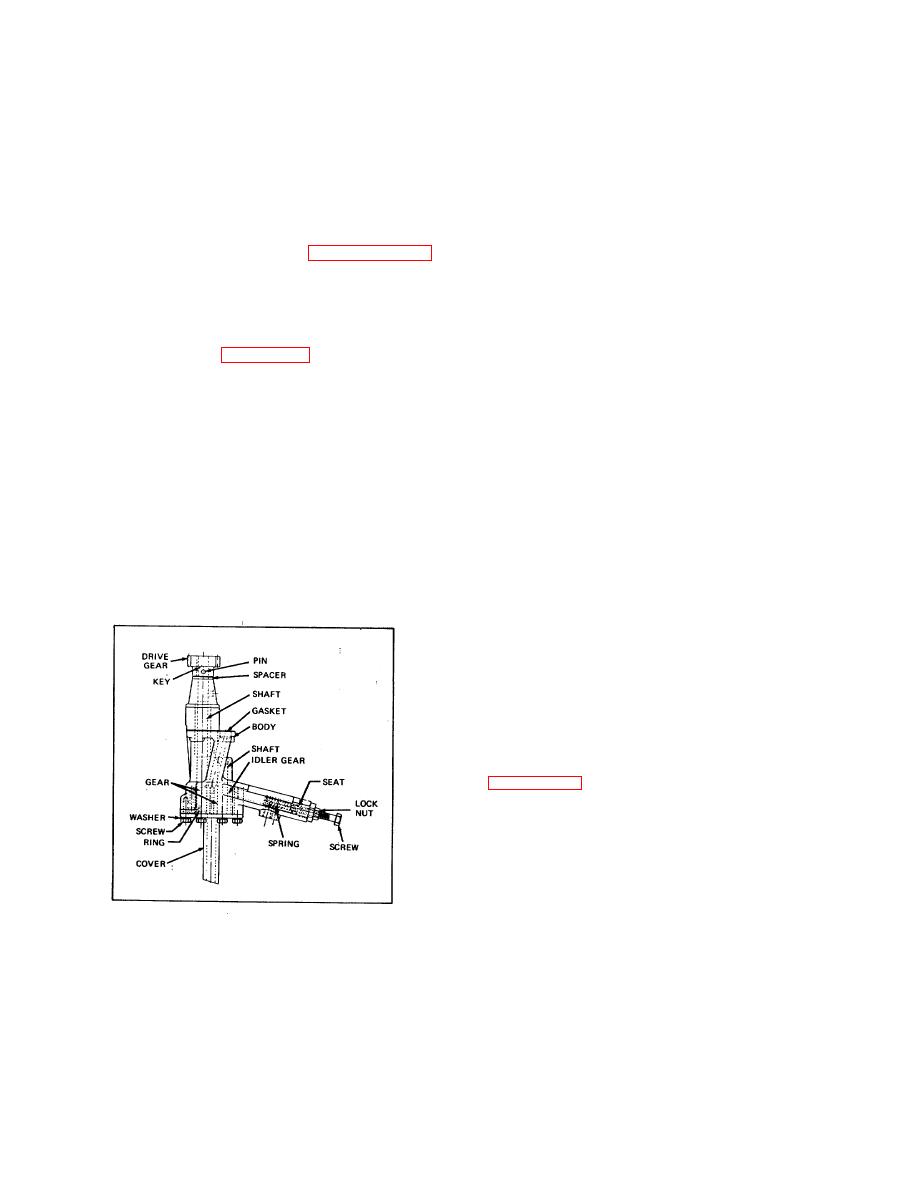

(1) Remove pin (Figure 6-22) from drive gear,

teeth or between gear ends and body before proceeding.

pull gear from shaft and remove key.

(6) Install cover and tighten screws.

(2) Remove screws and pump cover.

d. Installation. Reverse a. above.

(3) Remove idler gear and shaft.

e. Adjustment. Adjust pump pressure with the

(4) Pull main shaft down through pump body to

engine running after reassembly, as follows:

remove it.

(1) With engine warmed up, and operating at a

(5) Press idler gear shaft out of gear.

fast idle speed, remove plug at side of oil pan, as shown.

(6) Press main shaft through oil pump

(2) Loosen locknut on pump with crowfoot

gear approximately 3/8 inches and remove snap ring.

wrench, and adjust screw so pressure gauge indicates

Then press shaft out of gear.

26 psi at 1600 rpm with oil at operating temperature of

about 140 deg F.

(3) Tighten locknut to hold setting, check

pressure after tightening, and replace oil pan side plug.

6-59. OIL FILTER.

a. Element replacement.

(1) Unscrew bolt in center of oil filter cover

Discard gasket.

(2) Lift out filter element carefully to avoid getting

dirty oil on truck or clothing. Discard element.

(3) Clean residue from inside filter housing, wipe

outside clean, install new element and cover gasket, and

reinstall cover and cover screw.

Figure 6-22. Oil Pump

b. Filter and lines removal.

(1) Remove and tag leads to hourmeter switch

and oil pressure transmitter, and remove switch and

transmitter from cross.

91

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |