|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

c. Installation. Reverse a. above.

d. Adjustment. Refer to paragraph 6-25h.

6-27. PROPELLER SHAFT.

a. Removal and disassembly.

OE or specified lubricant immediately on drying. Avoid

handling dry parts with bare hands before applying

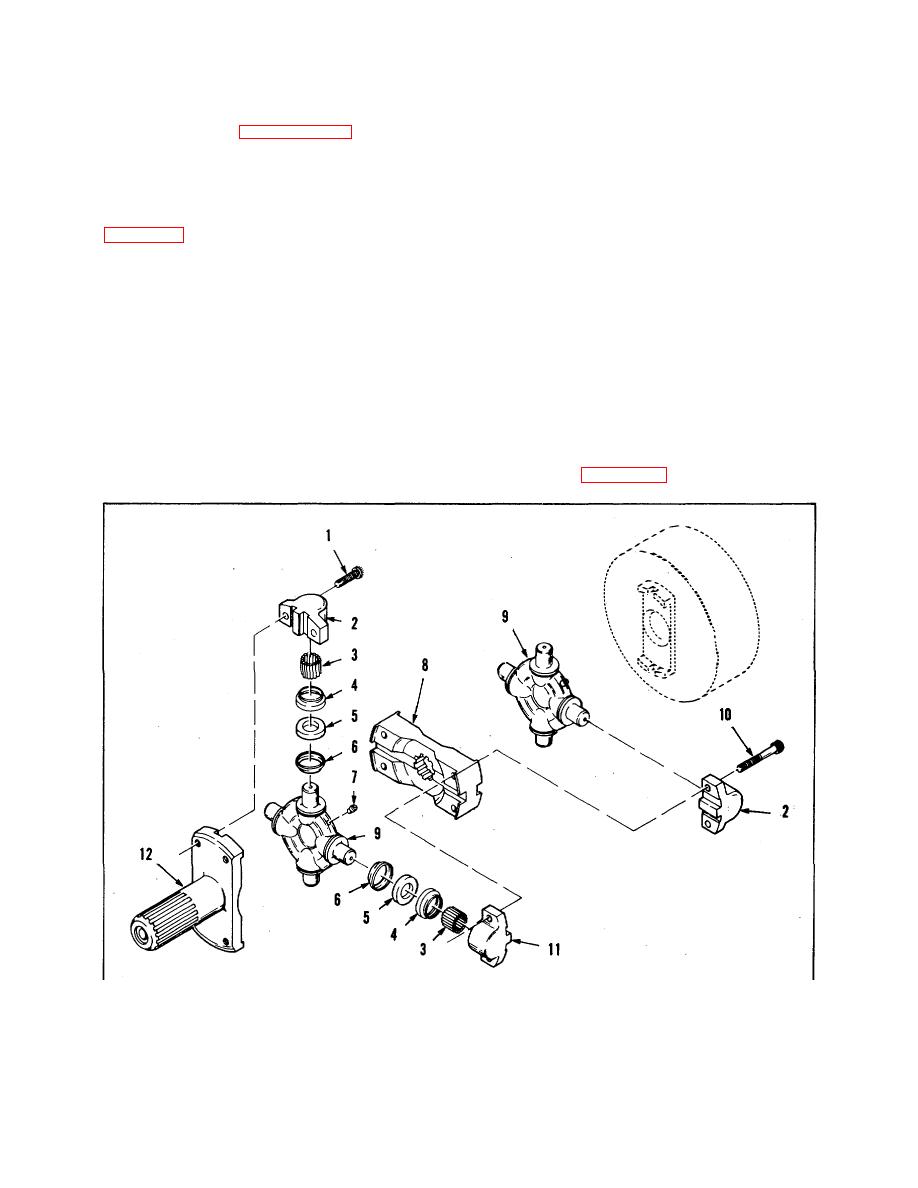

(1) Remove lock wire and take out screws (1

lubricant.

and 10, figure 6-14).

c. Inspection. Inspect bearings, rollers, and bearing

(2) Tap or pry stub yoke (12), as needed, to free

surfaces of spiders for galling, rust, or signs of wear or

bearings (2 and 11) from arced pilot surfaces of yoke,

failure. Inspect all splines for signs of damage or wear.

and coupling plates (8). Remove bearing (2) with rollers

Check all threads for stripping or cross-thread damage.

(3), collar (4), cork washer (5), and dust shield (6).

Check all flanges and machined surfaces for nicks or

Remove rear spider (9).

dents.

(3) Pry coupling plate from front spider (9) and

d. Assembly and installation.

pry spider from handbrake' drum to free remaining

bearings. Remove bearings. Discard cork washers (5).

(1) Install stub yoke splined end as far as it will

go into transmission output shaft.

b. Cleaning. Clean all parts thoroughly in SD.

Probe lubrication passages through fitting (7) and

(2) Install items 2, 3, 4, 5, 6 and 11 as illustrated

spiders, to be sure no foreign matter or hard grease

horizontally in Figure 6-14, to both spiders (9). Squeeze

soap will prevent lubrication. Coat reusable parts with

1.

Capscrew

5.

Washer

9. Universal joint spider

2.

Needle bearing

6.

Dust shield

10. Capscrew

3.

Rollers

7.

Lubrication fitting

11. Needle bearing

4.

Collar

8.

Coupling plate

Stub yoke

Figure 6-14. Propeller Shaft, Exploded View

71

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |