|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

5-73. STEERING SYSTEM.

5-74. STEERING LINKAGE ADJUSTMENT (FIGURE

5-12).

a. Assemble ball joint (1) on the cylinder so that the

thread engagement is approximately 1-1/2 inches.

b. When performing adjustments in c. and d.

below, there should be no restraint on the cylinder or

pitman arm due to stops on trailing axle. To insure this,

ball joint (2) should be removed from the steering axle

bellcrank, but should be maintained in line with the hole

in the bellcrank.

c. With drag link (3) in place, turn steering wheel

full right with stop screw (4) backed off. Remove ball

joint (5) from pitman arm and pull drag link until the

cylinder (6) is at the end of stroke. Adjust ball joint and

temporarily assemble in pitman arm. Turn stop screw

until it touches pitman arm. Disconnect ball joint from

pitman arm and then three turns counterclockwise to

increase drag link length. Assemble to pitman arm.

Back off pitman arm with steering wheel, turn stop screw

one additional turn and lock in position with locknut.

d. Turn steering wheel full left with stop screw (7)

backed off until steering cylinder has extended 11-1/2

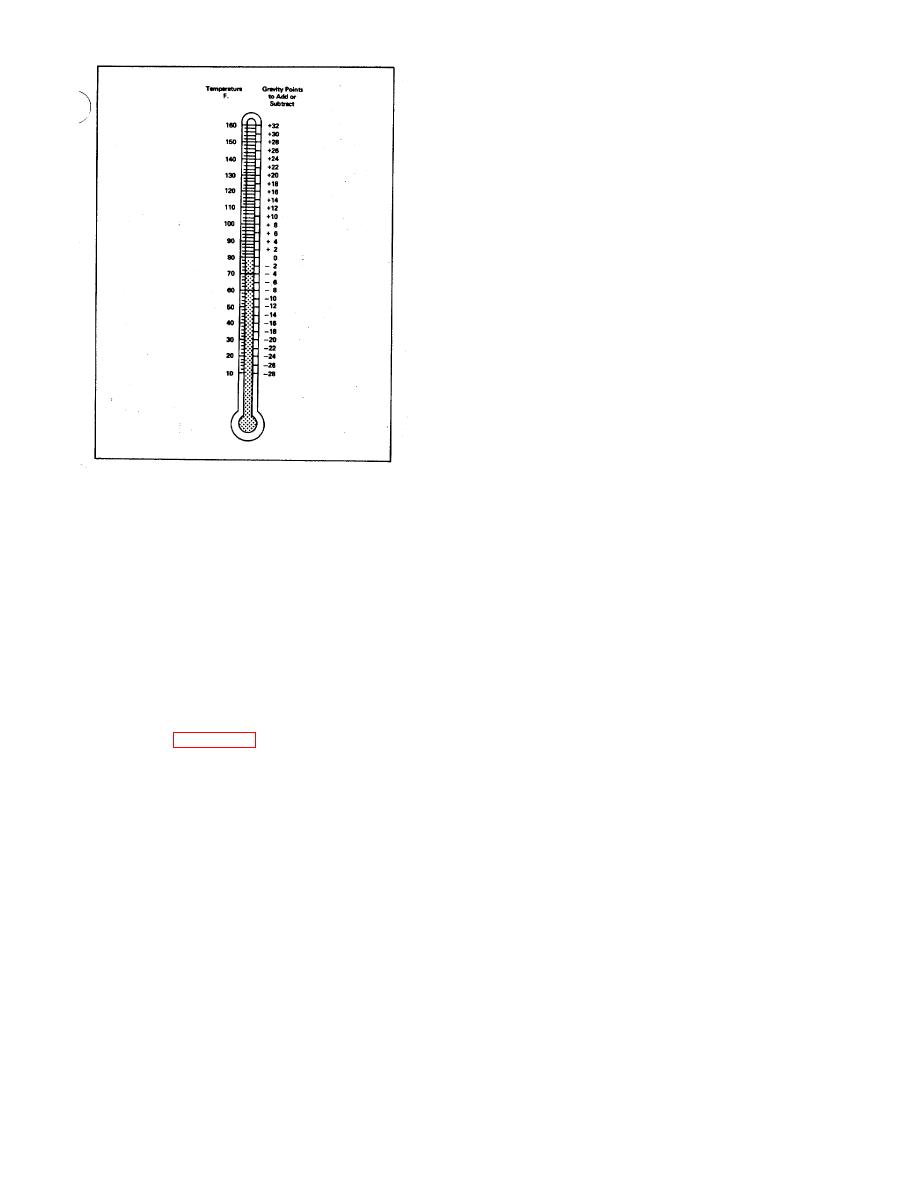

Figure 5-11. Battery Test

inches from adjusted position for right turn, as in c.

above. Bring stop screw in contact with pitman arm and

indicates a fully charged battery. A specific gravity

lock in place with lock nut.

reading of 1.220 or less in each cell indicates that the

e. Adjust rod (8) so that equal angles of steering

battery must be recharged or replaced.

wheels are obtained when steering wheel is turned from

full right to full left. Major adjustment of rod (8) length

NOTE

must be made using only ball joint (2) while rod is

A temperature-corrected specific

threader into cylinder to make dimension 12-3/4 inches.

gravity measurement is obtained by

Final adjustment may be made by turning rod (8) with

adding 0.004 to the actual hydrometer

ball joint (2) assembled in bellcrank. Do not turn rod

reading for each 10 deg F the

more than one turn in either direction or the thread

electrolyte is above 80 deg F or

engagement will be below minimum required.

subtracting 0.004 from the actual

f. Before final clamping of rod (8), position cylinder

hydrometer reading for each 10 deg F

as shown.

the electrolyte is below 80 deg F, as

shown in figure 5-11.

NOTE

After final adjustment, the entire

5-71. ADDING WATER TO BATTERY. The water in

linkage and wheels must be stopped

the battery electrolyte solution evaporates at high

only on the pitman arm stop screws

temperatures or with excessive charging rates. Inspect

(4 and 7).

Cylinder should have

the electrolyte level and add distilled water when

approximately 1/4 inch of stroke left

necessary to bring electrolyte level to 3/4 inch above the

at full right or full left turn.

plate separators.

5-75. SERVICE BRAKE SYSTEM SERVICING.

5-72. BATTERY CLEANING. The top of the battery

must be kept clean. Tighten vent plugs and clean

5-76. WHEEL BRAKE ADJUSTMENT. Since the wheel

battery with a brush dipped in an alkaline solution such

brakes used on the trucks are self-adjusting, no manual

as ammonia or a solution of bicarbonate of soda and

adjustment is required for the life of the brake linings.

water. If terminals and cable clamps are corroded,

However, two hexagon loads extend through each

disconnect cables and clean in same manner as battery.

backing from the adjusting cams. If the drums are worn

from long service, to the extent that they cannot be

readily removed

37

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |