|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-621-34

provided through which the timing marks on the

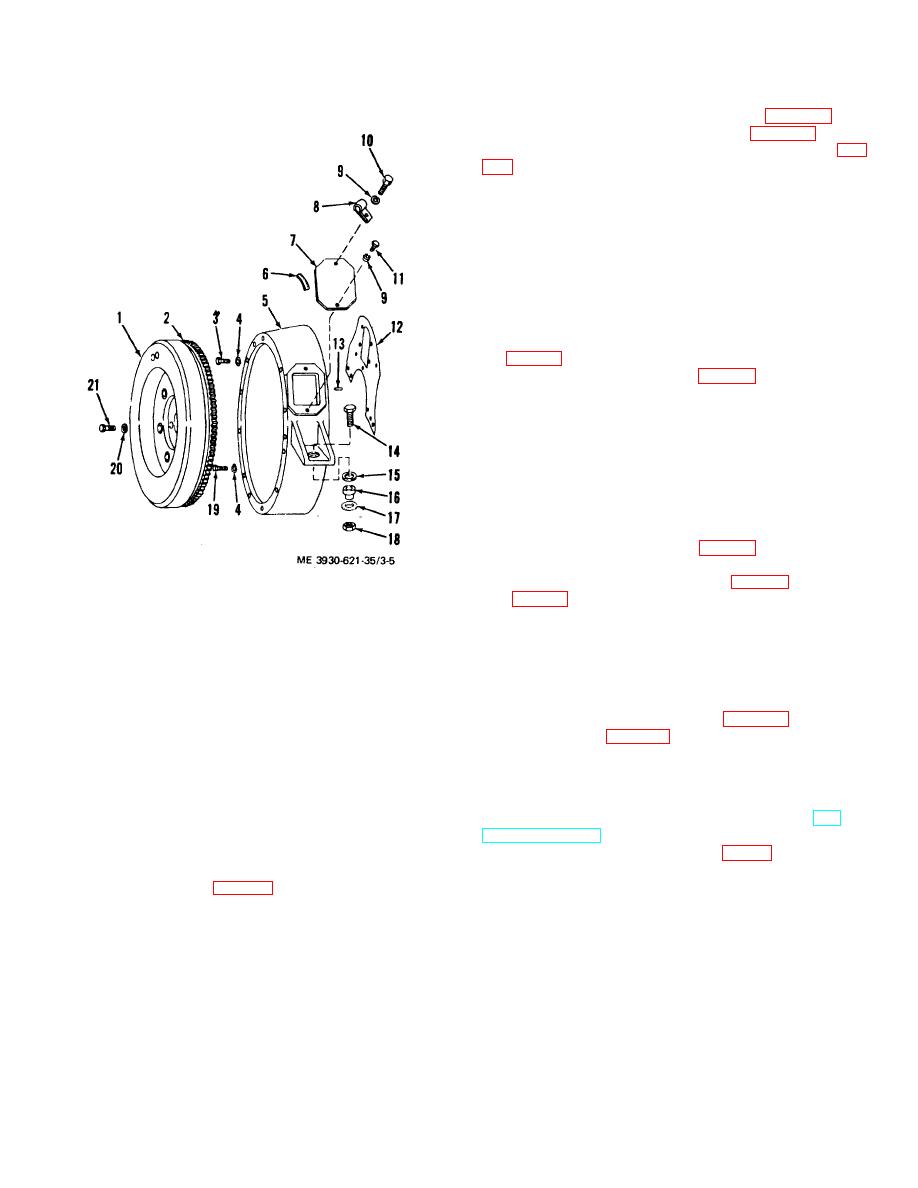

3-13. Removal

timing strip may be seen. Two engine mounting

a. Remove engine assembly from truck (para 2-5).

b. Remove transmission from engine (para 2-6).

c. Remove the lockwires from the four bolts (21, fig.

flywheel to flange.

Caution: Do not mix special fly wheel

retaining bolts (21) with others. Do not use ordinary

bolts, since flywheel bolts are under great stress in

normal use.

d. Remove flywheel (1).

e. If necessary to remove starter ring gear (2), heat

gear and cut out with chisel.

f. Remove the three bolts (9O) and lock washers

(4) holding the main bearing assembly closure plate

(3, fig. 3-3) and remove plate.

g. Remove the five screws (3, fig. 3-5) and lock

washers (4) holding the flywheel housing t5) to the

cylinder block and remove housing.

3-14. Cleaning and Inspection

a. Clean all parts with a cleaning compound, solvent

(Spec. P-S-661). Dry thoroughly using compressed air.

b. Check ring gear for cracks, chipped teeth, and

other damage or wear.

c. Replace damaged parts as authorized.

3-15. Installation

a. Install flywheel housing (5, fig. 3-5) on engine block

with screws (3) and lock washers (4).

b. Install bearing closure plate (3, fig. 3-3) with bolts

3. Screw

14.

Mounting cap screw

(19, fig. 3-5) and lock washers (4).

4 Lock washer

15.

Alining washer

c. Heat starter ring gear (2) and press gear on

5. Flywheel housing

16.

Mount

flywheel.

6. Timing strip

17.

Flat washer

d. Install flywheel (1 ) and secure with bolts (21 )and

7. Access cover

18.

Self-locking nut

lock washers (20). Be sure to use special flywheel

8. Loop clamp

19.

Closure machine bolt

9. Lock washer

20.

Flywheel lock washer

bolts.-

10. Machine bolt

21.

Flywheel bolt

e. Install lockwires on bolts (21).

11. Machine bolt

f. Install transmission on engine para 2-6)and engine

assembly in truck (para 2-5).

Figure 3-5. Flywheel assembly, exploded view.

Section V. VALVES, SPRINGS, GUIDE, SEATS AND TARPET ASSEMBLIES

(2) Remove valve covers on side of engine block (TM

3-16. Description

10-3930-621-12).

(3) Raise spring retainer (5, fig 3-6) until the two

The valve tappets and valves are of the mushroom type.

wedge shaped lock, (6, drop out from between the cap

Valve springs are held to the valve stem by a pair of

(7) and retainer.

wedge shaped locks (6, fig. 3-6) between the stem and

(4) Lift valves (1), retainer caps (7) , retainers

spring retainer (5). The valves operate in replaceable

(5), and springs (4) out of engine.

guides (2) and (3) and seats.

(5) Place valves in numbered holes., in a board

3-17. Valves and Springs

to make sure of reinstallation in their original positions.

a. Removal.

(1) Remove cylinder head (TM 10-3930-621-

12).

3-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |