|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

protection when using compressed

air.

(1) Clean all parts in approved solvent and dry

using compressed air.

(2) Inspect for worn or damaged springs and

ball seats.

(3) Inspect for damaged threads.

d. Reassembly.

(1) Apply a coat of oil to ball seat. (LO 10-

3930-620-12.)

(2) Reassemble drag link internal parts in the

reverse of figure 3-69.

e. Adjustment. The drag link assembly is adjusted,

after installation, according to paragraph 2-20.

3-38. Power Steering Cylinder

a. Removal. Remove the power steering cylinder

(TM 10-3930-620-12).

b. Disassembly.

(1) Remove the lock ring (1, fig. 3-70)

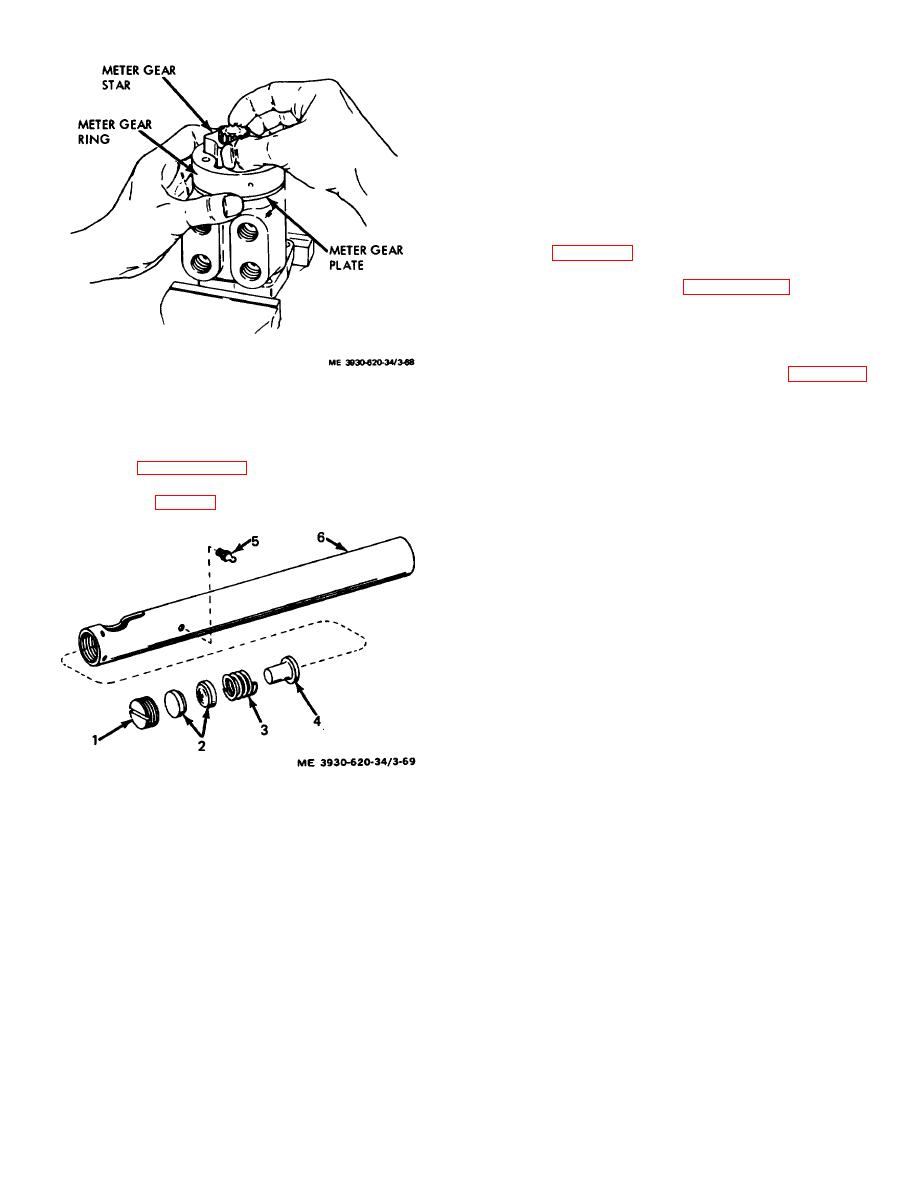

Figure 3-68. Meter gear star being installed.

securing the spacer (2) in position and remove the

spacer.

3-37. Drag Link Assembly

(2) Remove the lock ring (3) securing the

head (4) in the cylinder (15) and remove the head from

a. Removal. Remove the drag link assembly

the cylinder by pulling out the rod and piston assembly.

according to paragraph 2-20.

(3) Carefully slide the head off the rod (14).

b. Disassembly. Remove adjusting plug and

Remove the wiper ring (6), backup ring (7), and packing

internal parts. ( fig. 3-69.)

(8) from the head.

(4) Remove the nut (9) securing the piston

(10) to the rod (14). Slide the piston off the rod.

(5) Remove the backup rings (12) and the

packing (13) from the piston. Remove the rod seal (11)

from the rod.

(6) If the lubrication fitting (17) is damaged,

replace it.

(7) If the bushing (16) requires replacement,

press it out with a suitable tool or arbor press.

c. Cleaning, Inspection and Repair.

(1) Clean the metal parts in a suitable solvent

and dry them with compressed air. Wipe the seals clean,

using hydraulic oil as a solvent.

(2) Inspect the tube bore, rod, head, and

piston for cracks, scratches, scoring or other damage,

and excessive wear. Inspect the seals for damage or

excessive wear.

1 Adjusting plug

(3) Slight imperfections can be cleaned up

2. Ball socket seat (21

with a polishing stone. Replace any damaged or

3. Spring

excessively worn parts.

4. Spring seat

d. Reassembly. Reassemble the cylinder by

5. Lubrication Fitting

reversing the disassembly procedure. Lubricate the

6. Drag link

cylinder parts with a light coating of hydraulic oil. Be

careful not to damage seals against threads or sharp

Figure 3-69. Drag link. exploded view.

edges during reassembly. When installing the head

assembly, compress the lock ring. Keep it compressed

c. Cleaning Inspection.

while sliding the head into the tube until the lock ring can

snap into place.

Warning: Use

an

approved

cleaning solvent. Wear suitable eye

3-79

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |