|

|||

|

|

|||

|

Page Title:

Chapter 2. ORGANIZATIONAL MAINTENANCE INSTRUCTIONS |

|

||

| ||||||||||

|

|

CHAPTER 2

ORGANIZATIONAL MAINTENANCE INSTRUCTIONS

Section I. SERVICE UPON RECEIPT OF MATERIAL

radiator for proper coolant level and engine for proper

2-1. Inspecting and Servicing the

engine oil level. Inflate tires to proper pressure. Check

Equipment

battery for proper electrolyte level and transmission

Inspect the truck for any signs of damage. Check

for proper oil level. Fill fuel tank.

Section II. REPAIR PARTS, SPECIAL TOOLS AND EQUIPMENT

2-4. Repair Parts

2-2. Tools and Equipment

Repair parts and equipment are listed and illustrated

No tools or equipment are authorized for organiza-

in TM 10-3930-618-20P.

tional maintenance.

2-3. Special Tools and Equipment

No special tools or equipment are authorized for organi-

zational maintenance.

Section Ill. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

2-6. Quarterly Preventive Maintenance

2-5. General

Services

To insure that the truck is ready for operation at all

The sequence numbers indicate the sequence of mini-

times, it must be inspected systematically so that

mum inspection requirements. The letter after the

defects may be discovered and corrected before they

sequence number indicates the special frequency

result in serious damage or failure. Defects discovered

required for this check. If no letter is shown in column

during operation of the truck will be noted for future

one of the table, the check is to be made on a quarterly

correction, to be made as soon as operation has ceased.

basis. See legend at bottom of table 2-1.

Stop operation immediately if a deficiency is noted

during operation which would damage the equipment

if operation were continued.

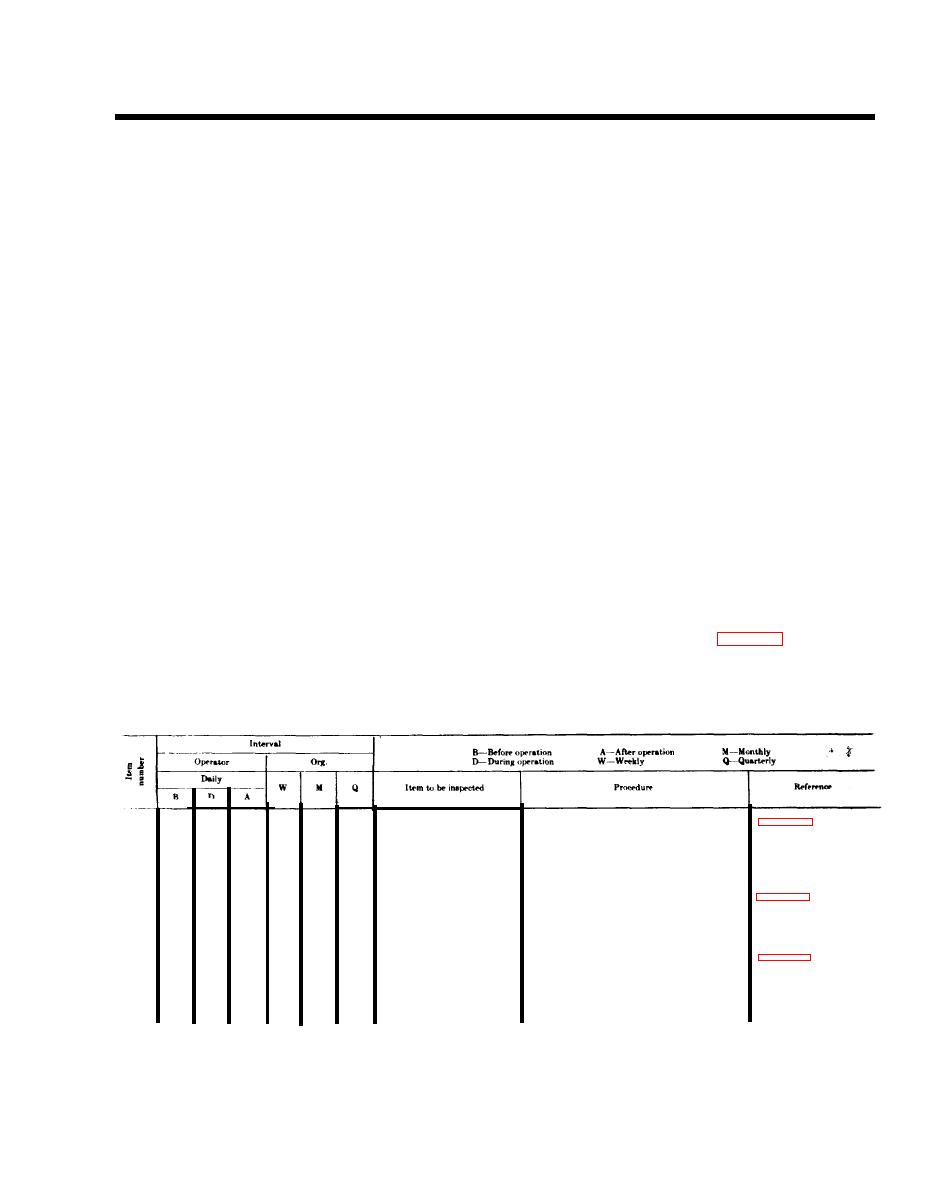

Table 2-1. Preventive Maintenance Checks and Services

X

1

Check for improper fluid level.

Refer to

Brake Master Cylinder

current LO and refill to within 3/8 in. to

1/2 in. from top of reservoir. Inspect for

leaks and insecure mounting. Check tiller

cap vent for clogged condition.

X

2

Inspect battery for cracks and breaks. In-

Battery and Cables

spect cables and terminals for corrosion

and breaks. Inspect battery frame for

security, breaks and corrosion.

X

3

Distributor

Inspect for cracks, carbon streaks, corroded

terminals. and insecure mounting. In-

spect contact points for burns, pits,

and improper

frosting,

misalignment,

setting.

Adjust

gap.

2-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |