|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(5) Remove the screws holding the master cylin-

(b) Remove the floor plate and remove the pin

der assembly to the inside of the frame and remove

from the lower cable yoke. Loosen the yoke locknut

the cylinder.

(c) Turn the yoke 3 or 4 turns clockwise to

shorten the cable length.

(d) Install the yoke on the brake lever and

check adjustment by engaging the brake. Readjust as

necessary to prevent the brakeshoes from dragging

when disengaged.

(e) Tighten the yoke locknut and install the

pin.

(f) Install and tighten the setscrew in the

adjusting knob.

2-52. Brake Pedal and Linkage Ad-

justment

The ideal pedal free play is %-inch. Too little free

travel will prevent the master cylinder piston from

returning to full OFF position and the brakes will

begin to drag after several applications. Excessive

free travel will reduce the usable stroke of the master

cylinder. Refer to figure 2-37 and adjust as follows:

a. Remove the floor plates.

b. Slowly depress the brake pedal and check for

1/2-inch free travel. Also observe push rod action.

c. To obtain the proper free travel, loosen the

locknut on the clevis and then turn the adjusting nut.

d. Tighten the locknut and reinstall the floor plates.

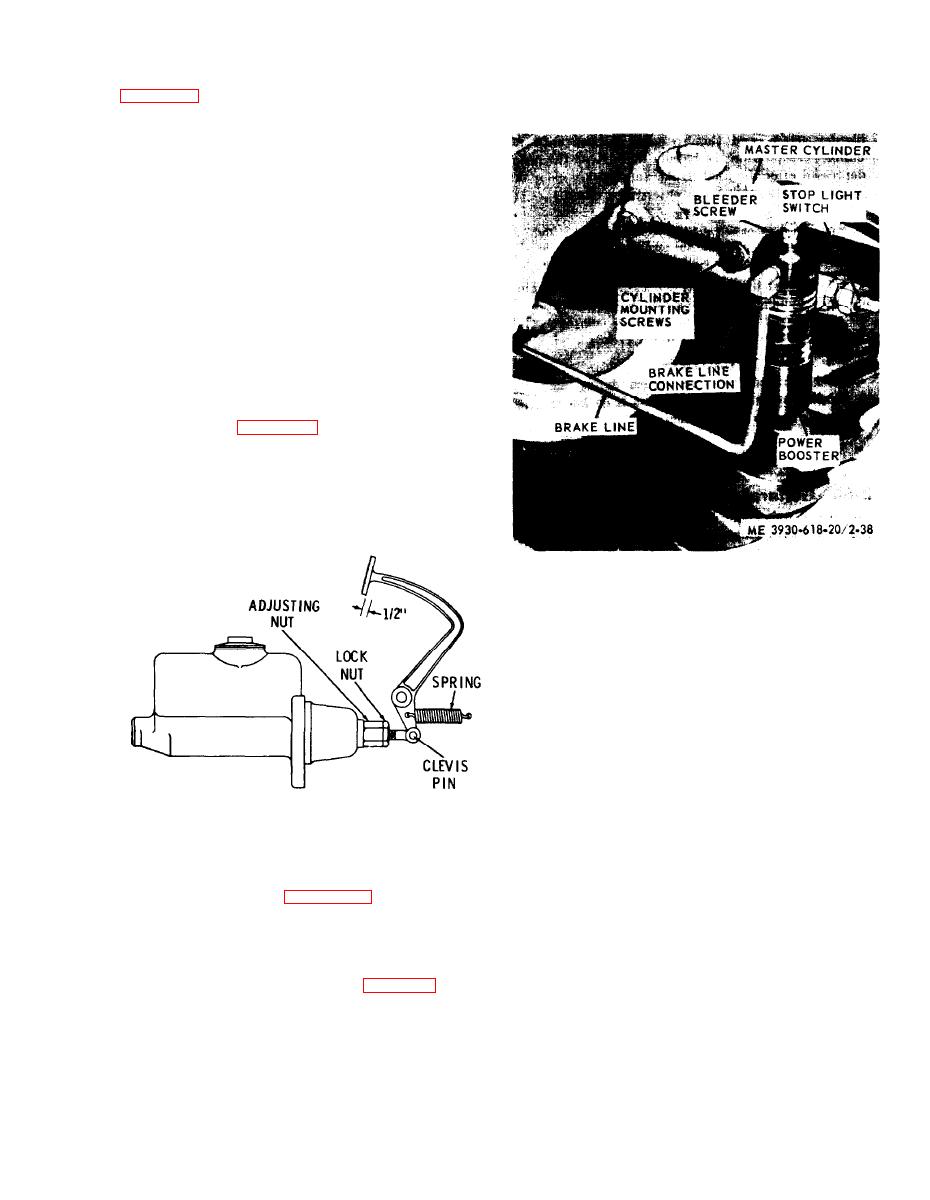

Figure 2-38. Brake master cylinder and brake power booster.

installed view

b. Installation. Reverse procedures in a above. Bleed

the brake hydraulic system as instructed in c below.

c. Bleeding the Brake Hydraulic System. The fluid in

the brake hydraulic system must form a "solid"

column. To do this, the system must be bled of all air

or other gases. Bleeding of the brake system is required

each time the system is drained and refilled with new

fluid ; if some part of the system has been disconnected

for any reason; if the fluid level in the master cylinder

is allowed to decrease to a point where air enters the

system; if the air has entered the system due to a

ME 3930-618-20/2-37

defective master cylinder or wheel cylinders; or if the

brake pedal feels spongy. There is a bleeder screw on

Figure 2-37. Brake pedal adjustment.

each wheel cylinder and on the power booster. To bleed

the system, proceed as follows :

2-53. Brake Master Cylinder

(1) Fill the master cylinder to the proper level

(3/8- to 1/2-in. from the reservoir top).

(2) If a refiller or pressure bleeder is used, place

master cylinder assembly as follows :

the proper adapter in the master cylinder fillercap

(1) Remove the floor plate.

opening and install the refiller or pressure bleeder.

(2) Disconnect the electrical wires at the stop-

(3) Install a bleeder hose on the bleeder screw of

light switch.

either wheel cylinder. Submerge the loose end of the

(3) Remove the power booster (para 2-54).

hose in brake fluid in a glass jar.

(4) Remove the clevis pin holding the pushrod to

(4) Open the bleeder screw one turn.

the brake pedal.

2-43

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |