|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

Conversely, a lead-acid battery installed in the truck

c.

Adjust plugging severity as follows:

calibrated and run from a nickel-iron alkaline battery will

(1) Operate the truck at a maximum forward

pass excessive current. The current limit must be set

speed. If previous adjustments (para 6-244 through 6-

for a maximum of 200 amperes for either battery.

248) have been properly made, truck will come to

Excess current will cause a lurch in speed as the

maximum speed smoothly.

acceleration passes from the SCR controlled

acceleration to the field weakening controlled maximum

(2) Move direction control lever (82, figure 7-

speed.

2) to reverse position without releasing accelerator or

CAUTION

applying service brakes. Determine severity of direction

change.

Replace the battery with a similar battery or

recalibrate current limit (para 6-245) to prevent

(3) If plugging reaction is too severe, adjust

truck lurch. Excess current may also damage

SCR control pack No. 5RH trimmer (figure 62)

the SCR control pack.

counterclockwise to reduce severity. If plugging is too

soft, adjust clockwise. Repeat step (2) above until

6-253. BATTERY DESCRIPTION. Batteries differ in

correctly adjusted.

appearance as follows:

a. Lead-Acid Battery. The lead-acid battery is

(4) Replace SCR control pack cover and

constructed with all cells built into one case. The battery

control panel cover.

case top is filled and sealed between the cells.

6-250.

INDIVIDUAL ADJUSTMENTS.

When

b. Nickel-Iron Alkaline Battery. This battery is

necessary, any one or more of above adjustments can

composed of individual separate cells arranged in a

be made without completing the complete sequence.

carrying tray or case. Each cell is joined by a connector

The following chart is a summary of adjustment steps

cable with cells hooked in series. Cells are separated

and preparation required (para 6-243).

from each other within the case.

6-251. BATTERY TYPES.

6-254. BATTERY COMPARTMENT. Each truck is

constructed with battery clamps welded to the truck in a

6-252. GENERAL. This truck may be operated from

location permitting installation of only one type battery.

either a lead-acid or nickel-iron alkaline battery. Either

If the battery is to be changed to the other style, the

battery will provide the required voltage but due to its

brackets must be relocated.

construction and materials, the current limit must be

calibrated for the type battery installed. The current

6-255. DEFECTIVE MATERIAL. Return unserviceable

output of the nickel-iron alkaline battery will not provide

items to supporting maintenance units for determination

sufficient current to satisfactorily operate the truck that

of feasibility of action under warranty.

has been calibrated and run on a lead-acid battery.

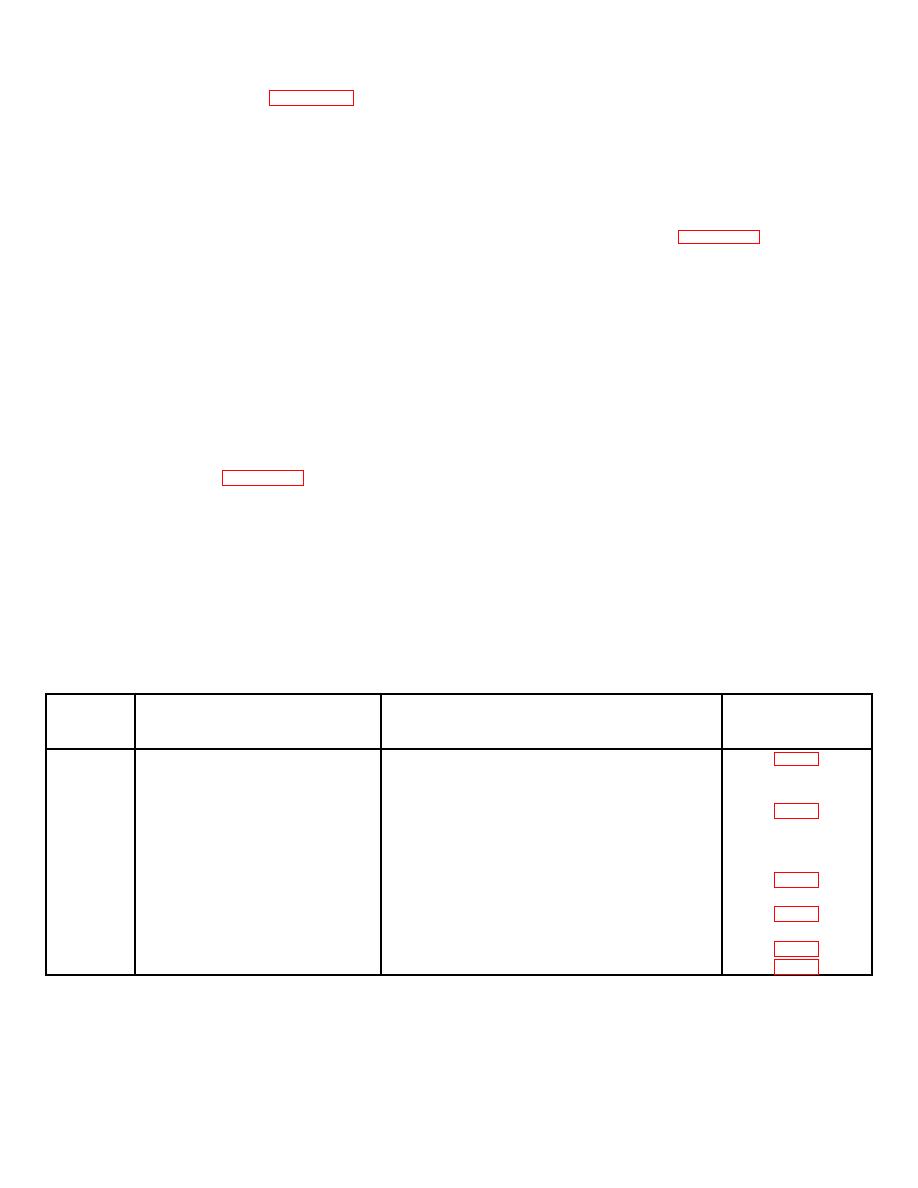

Para

Adjustment

Preparation

Ref

1.

Field Weakening

a.

Lift drive axle

b.

Connect ammeter and shunt

c.

Jump brake switch

2.

Current Limit

a.

Lift drive axle

b.

Connect ammeter and shunt

c.

Jump brake switch

d.

Disconnect ARP no. 5 lead

3.

Creep Speed

a.

Disconnect ARP no. 5 lead

b.

Operate truck

4.

Acceleration Time

a.

Disconnect ARP no. 5 lead

b.

Operate truck

5.

Shorting Contactor Time Delay

a.

Operate truck

6.

Plugging

a.

Operate truck

6-52

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |