|

|||

|

|

|||

|

Page Title:

Section VI. STEERING GEAR OVERHAUL |

|

||

| ||||||||||

|

|

TM 10-3930-609-35

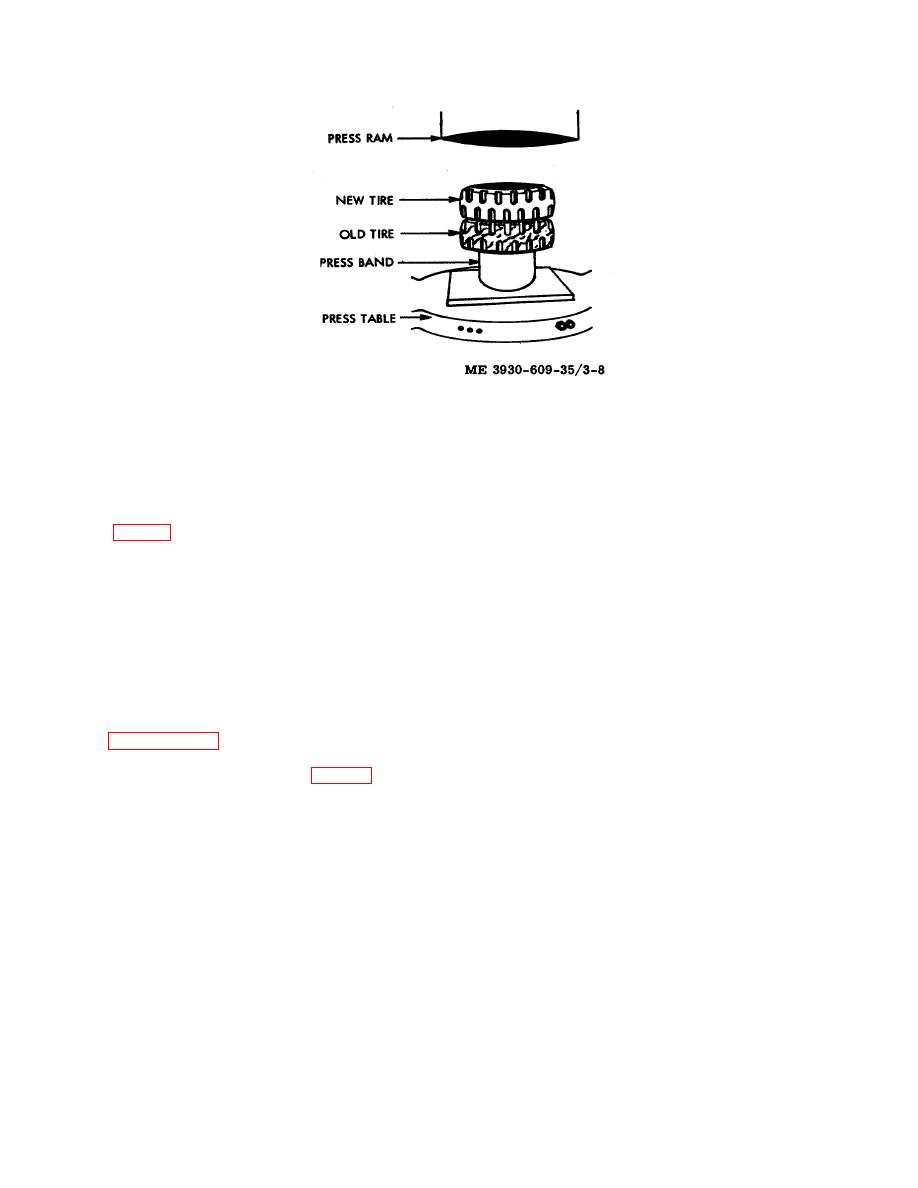

Figure 3-8. Solid rubber tire replacement.

Section VI. STEERING GEAR OVERHAUL

3-36. Description of Steering Gear

f. Pull side cover, gasket and pitman shaft gear

The steering gear consists of a worm shaft, ball nut,

from housing.

pitman shaft gear and associated parts mounted in a

Note

housing (fig. 3-9). Turning the wormshaft by means of

If pitman shaft gear does not clear

the steering wheel moves the ball nut along the lower

opening in housing, turn wormshaft

end of the wormshaft. Teeth in the wormshaft are

by hand until pitman shaft gear will

engaged with teeth in the pitman shaft gear, thus

pass through opening.

causing the shaft to rotate as the ball nut moves. The

g. Unscrew locknut from adjuster and unscrew

pitman arm is spline engaged on the projecting pitman

adjuster from end cover.

shaft gear and rotates with the shaft. The pitman arm is

h. Remove four screws and washer securing end

connected to the bellerank on the steering axle through

cover to housing and withdraw end cover, gasket and

the steering draglink.

bearing from housing.

Caution

3-37. Removal of Steering Gear

Use care when removing wormshaft

Removal of the steering gear is required for overhaul.

and ball nut from housing to prevent

Refer to paragraph 2-20 for removal procedure.

ball nut from running down to either

end of worm. Damage to ends of ball

3-38. Disassembly of Steering Gear (fig. 3-9)

guides will result if ball nut is

Note

allowed to rotate until stopped at end

Prior to start of disassembly, clean

of worm.

exterior of steering gear with SD.

i. Withdraw wormshaft and ball nut assembly from

a. Remove nut and washer from threaded end of

housing.

pitman shaft gear; then, use a puller to remove pitman

arm from pitman shaft gear.

j. Remove upper bearing from wormshaft.

b. Remove screw and washer securing bracket to

k. Unscrew lash adjuster from side cover and slide

housing and separate bracket from housing.

lash adjuster and shim out of slot in end of pitman shaft

gear.

c. Remove locknut from end of pitman shaft gear

and turn lash adjuster a few turns counterclockwise to

l. Remove seal from housing.

remove load from worm bearings.

m. If sleeve bearing in housing requires

d. Loosen locknut on worm bearing adjuster and

replacement, support housing in an arbor press and

turn adjuster a few turns counterclockwise.

press out bearing with a driver from lower end of

housing.

e. With a container placed under housing to catch

lubricant, remove three screws and washers which

attach side cover to housing.

3-14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |