|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-609-35

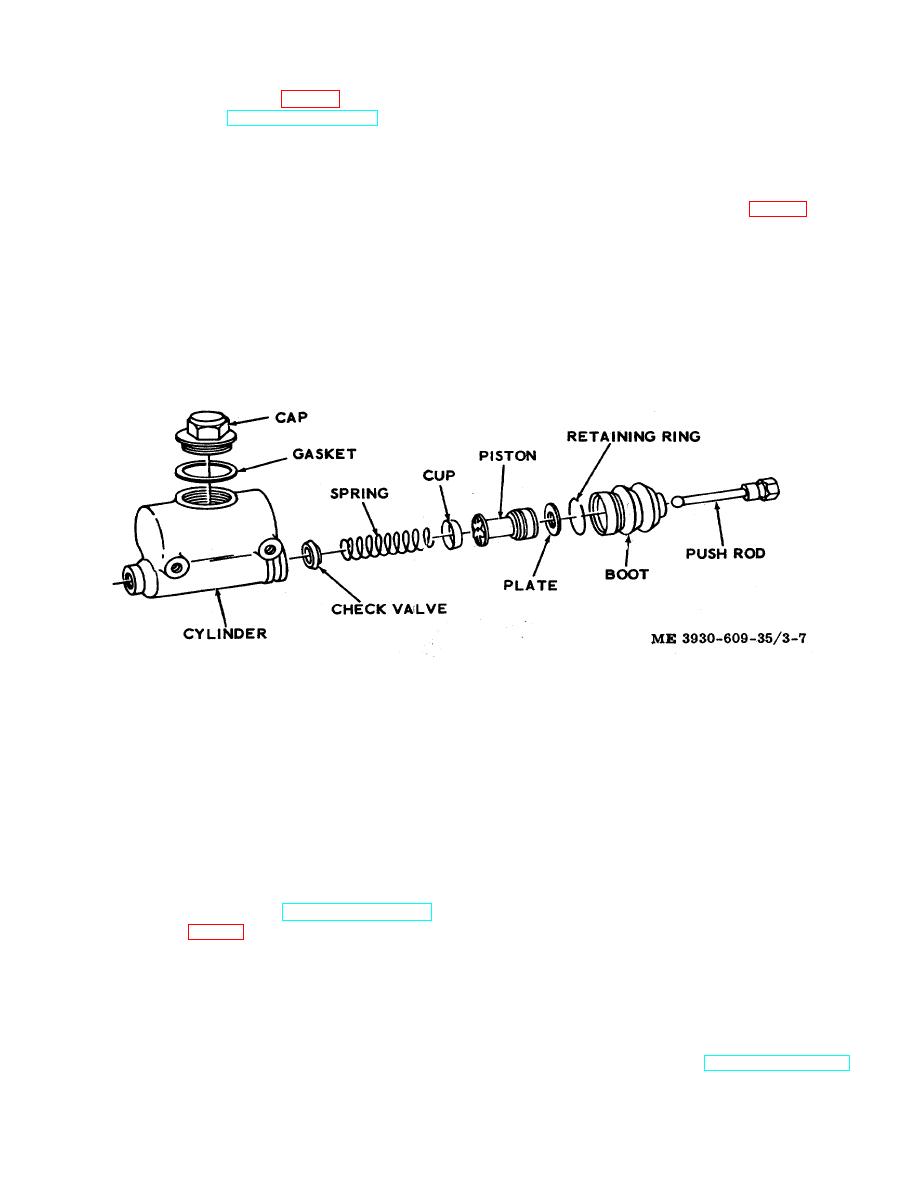

3-33. Repair of Master Cylinder (fig. 3-7)

(3) Hone cylinder bore to remove minor

roughness. If cylinder cannot be made serviceable by

a. Removal. Refer to TM 10-3930-609-12.

this method, replace entire master cylinder.

b. Disassembly.

(4) Replace any parts found to be defective

(1) Remove cap and gasket from cylinder.

and discard all parts for which replacements are

(2) Remove pushrod and boot from cylinder.

provided in master cylinder repair kit.

(3) Remove retaining ring from internal

d. Reassembly of Master Cylinder (fig. 3-7).

groove in cylinder and take out plate, piston, cup, spring

(1) Insert check valve, spring, cup, piston and

and check valve.

plate into bore of cylinder and install retaining ring to

c. Cleaning, Inspection, Repair and Replacement

secure parts.

of Master Cylinder Parts.

(2) Snap boot over end of cylinder and install

(1) Clean all reusable parts with alcohol.

push rod.

Flush reservoir in cylinder thoroughly and ensure that all

(3) Install cap and gasket in cylinder.

fluid passages are free of obstructions.

e. Installation of Master Cylinder. Refer to TM 10-

(2) Inspect bore in cylinder for any surface

3930-609-12.

roughness, particularly in the area of piston travel.

Figure 3-7. Master cylinder, exploded view.

Section V. TIRE REPLACEMENT

the rubber. Never hamper tire. Use ring rather than

3-34. General

block for supporting wheel and applying force to tire.

Replacement of tires is usually made by pressing off old

tire simultaneously with pressing on new tire. Force

required to replace a tire is 5,000 pounds for each inch

Note

of wheel diameter. For example, a tire used on a wheel

In some cases removal of old tire

18 inches in diameter requires 18 x 5,000 pounds or

may be difficult due to peened-over

90,000 pounds (45 tons) press capacity.

condition of base band or felloe. In

such cases, remove old tire by

3-35. Tire Replacement Procedure

burning or cutting through base

a. Remove wheel from truck (TM 10-3930-609-12).

band. In mounting tires on wheels

without old tires, use care to insure

a ring slightly smaller in diameter than wheel felloe and

that felloes are smooth and free of

at least as wide as tire to be pressed off.

burrs.

Also carefully check

alinement to assure that new tire

c. Place new tire over old and center carefully.

starts on squarely and is not cocked

d. Slowly lower press ram, check alinement, and

on wheel.

proceed with pressing operation.

e. Be sure that force is always applied through

g. Reinstall wheel on truck (TM 10-3930-609-12).

metal base band and that there is no interference with

3-13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |