|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-609-35

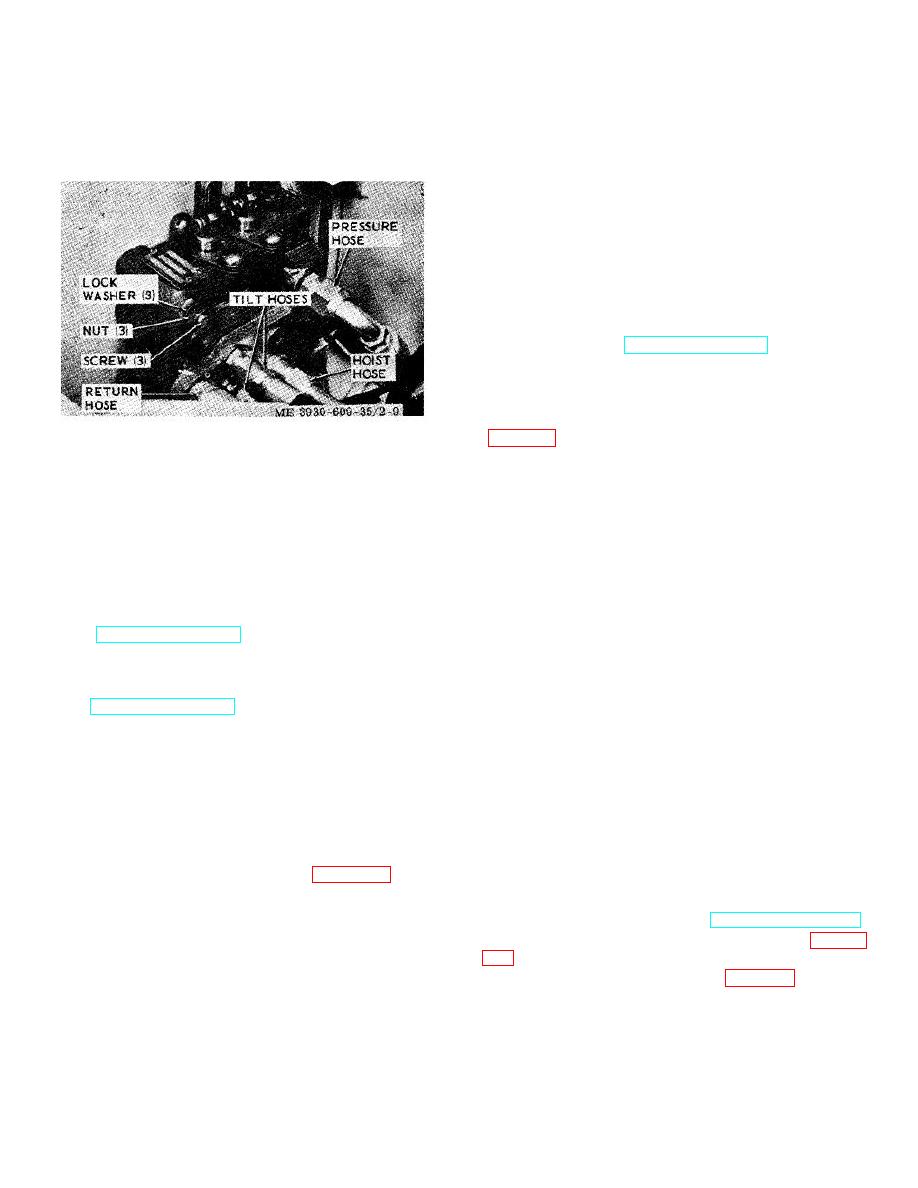

(3) Remove three screws, nuts and

(1) Position hydraulic tank on truck body and

secure with four screws and lockwashers.

lockwashers securing control valve to truck body and

remove control valve.

Screws are removed from

(2) Screw filters on hydraulic tank.

battery compartment side.

(3) Install return -hose to filter fitting and

tighten hose clamp securely.

(4) Install suction hose to bottom of hydraulic

tank and tighten hose clamp securely.

(5) Position seat on hydraulic tank and secure

with hinge pin.

(6) Fill hydraulic tank with oil (LO 10-3930-

609-12) and operate system to check for hydraulic fluid

leakage.

(7) At completion of operational test, install

cowl and floor plate (TM 10-3930-609-12).

2-19. Directional Control Switch

a. Removal.

(1) Remove directional control switch cover

Figure 2-9. Control valve removal.

leads.

(2) Remove return to neutral cable by

b. Installation.

loosening attaching screw.

(1) Install three control valve mounting

(3) Remove four screws securing directional

screws through. truck body from battery compartment

control switch and clamp to steering gear column and

side and mount control valve on screws. Secure with

remove clamp.

removed, nuts and lockwashers.

(4) Unscrew directional control switch off

(2) Reinstall removed hoses according to

conduit coupling and remove from truck.

tags attached at removal. Be certain hoses are tight.

b. Installation.

(3) Attach control valve linkage to control

(1)

Install directional control switch on

valve (TM 10-3930-609-12).

conduit coupling with lever oriented to right of steering

(4) Operate system while gradually increasing

gear column.

loads to check for proper operation and hydraulic fluid

(2) Secure switch to steering gear column

leakage. At completion of operational check-out, install

with clamp and four screws.

cowl (TM 10-3930-609-12).

(3) Secure return to neutral cable to switch

with attaching screw.

2-18. Hydraulic Oil Tank

(4)

With no pressure on operator's seat,

a. Removal.

switch should return to neutral from either the forward or

(1) Drain hydraulic oil from tank (LO 10-3930-

reverse directions.

609-12).

(5)

Reinstall electrical leads to switch

(2) Remove cowl and floor plate (TM 10-

according to tags attached at removal and attach switch

3930-609-12) and pull hinge pin securing seat to

cover.

hydraulic tank.

(3) Loosen hose clamp (fig. 2-10) and

2-20. Steering Gear

disconnect return hose between control valve and filter.

a. Removal.

(4) Loosen hose clamp and disconnect

(1) Remove floor plate (TM 10-3930-609-12).

suction hose at hydraulic tank.

(2) Remove directional control switch (para 2-

(5) Unscrew filters from hydraulic tank.

(6) Remove four screws and lockwashers

(3) Remove two covers (fig. 2-11) mounted

securing hydraulic tank to truck body and lift hydraulic

on steering gear column secured with two screws each

tank from truck.

and disconnect and tag horn leads at connector.

b. Installation.

2-14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |