|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

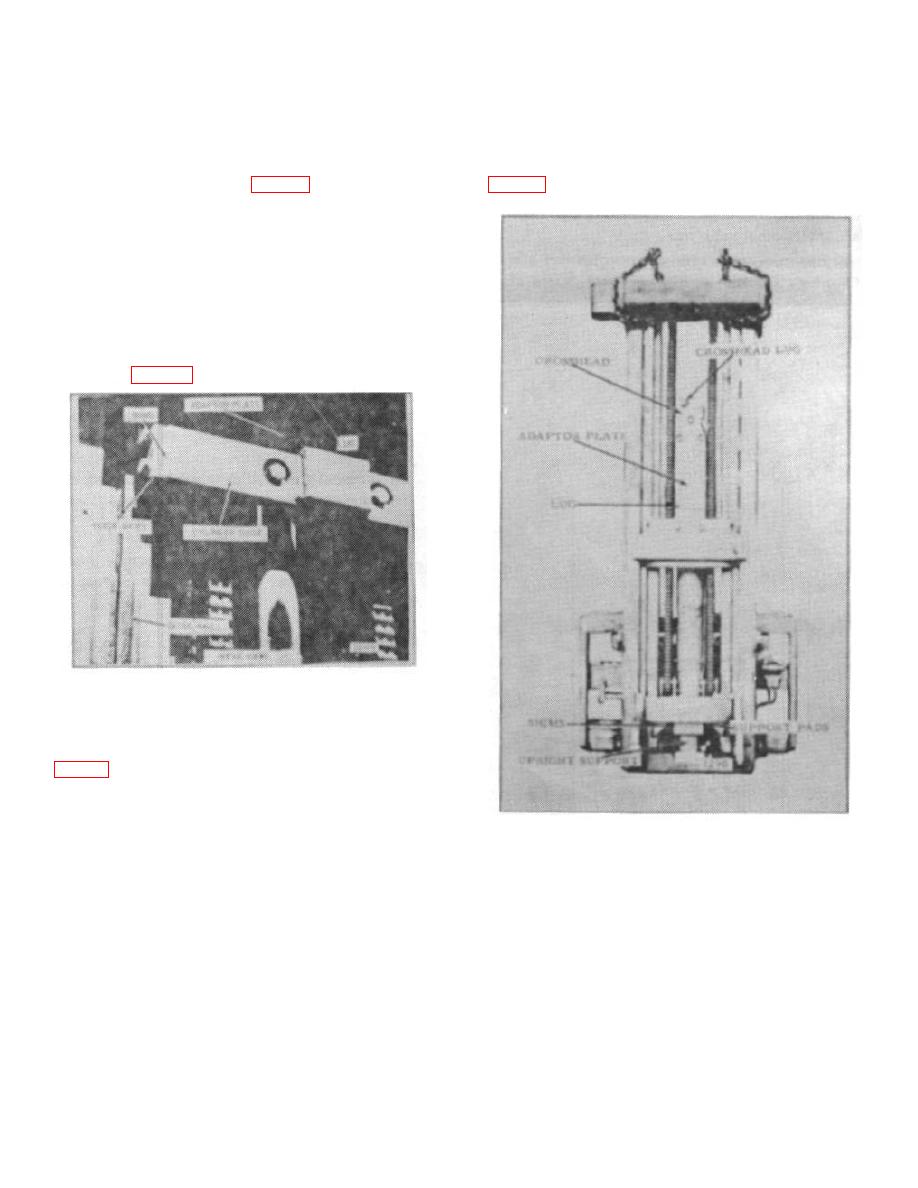

UPRIGHTS

the upper crossmember and one is on the front.

The hoist cylinder is supported by the lower

crossmember.

Attached to the crossmember and

The front latch and the right rear latch are splined and

positioned in back of the cylinder are two shim-adjusted

pads on which the inner and intermediate uprights rest.

pinned to a common shaft. Also on the front of the

same crossmember is a lug. (Fig. 20)

Situated on the inside front face at the top of each rear

channel flange is a shim-adjusted strip bearing. In front

of these bearings are two load rollers. Two more rollers

are located at the bottom, one on the outer side of each

channel.

Welded to the back of each channel is a cylinder guide

rail. Sliding on the rails is a cylinder guide. The guide is

shim-adjusted to the rails to slide freely with minimum

looseness. (Fig. 22)

Figure 22.

Outer Upright: A shim-adjusted strip bearing is located

on the front face at the top of each rear channel flange.

roller. In the same vicinity and attached to the back is a

stop plate. This plate is in line with the stop block on the

intermediate upright.

Figure 23.

Located on the front of the upper crossmember is a lug,

In the lowered position: The carriage is free to travel up;

which works in conjunction with the latching mechanism.

the inner upright is latched to the intermediate; the

intermediate upright is latched to the outer. The left

latch engages the intermediate upright and a right latch

engages the outer upright. Each latch is locked in

position by the adjacent latch.

At the beginning of the first stage of operation, the

B-182

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |