|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

UPRIGHTS

NOTE:

THREE-STAGE UPRIGHT ASSEMBLY

A length of wood 2 x 2 maybe inserted into

the top of the primary rod to aid in guiding

A. GENERAL

the rod out of the shell.

Besides a three-stage hoist cylinder, a crosshead and

5. Support the primary rod at both ends in a

guide assembly and a carriage, the three-stage upright

horizontal position. Remove the spiral lock from above

is made up of three upright assemblies: (1) Inner

the bushing at the bottom of the primary rod. Push the

Upright(2)Intermediate Upright (3) Outer Upright. The

bushing toward the top of the rod and remove the ring

crosshead and guide assembly includes a crosshead,

from the rod. Slide the bushing off.

adapter plate, and a cylinder guide.

D. CLEANING AND INSPECTION

CARRIAGE

1. Clean all parts in solvent. Stand the secondary

A. GENERAL

rod on end to allow oil and solvent to drain from above

the packing.

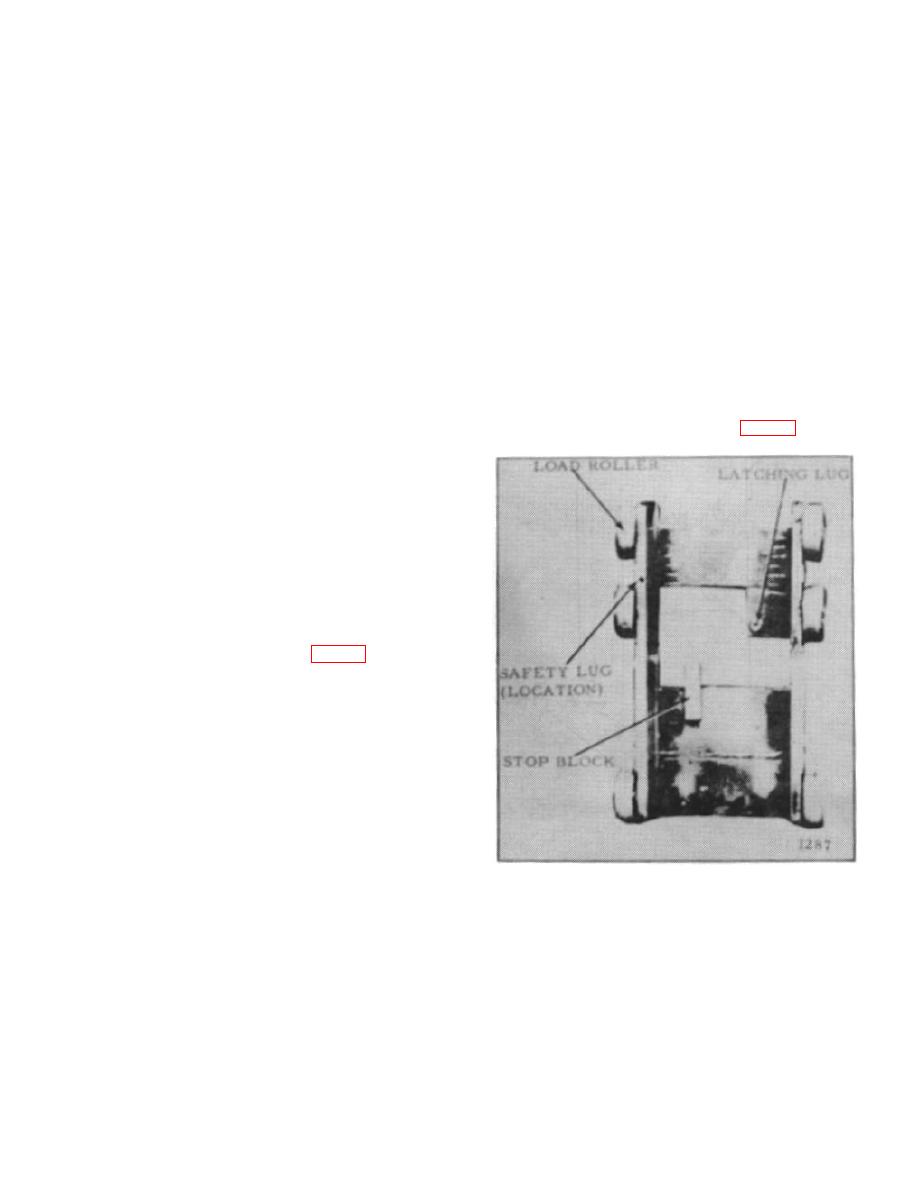

This is a hook-type assembly equipped with shim-

adjusted canted load rollers. It is also equipped with a

2. Check packing for rounded, worn, scratched or

lug and lifting block that works in conjunction with the

torn lips.

When installed in the primary bushing

latching mechanism on the uprights. (Fig. 18)

retainer, the packing should extend beyond the retainer.

The secondary packing should extend beyond the

piston. Replace packing if deteriorated, mutilated or if it

does not extend beyond its respective retainer or piston.

3. Check the rods for nicks, burrs, scratches and

rust.

Slight defects may be removed with fine

sandpaper. However, do not sand chrome plating off

the outside of either rod. Chrome plating on the rods

can be checked by applying copper sulfate to the rod.

The rod will discolor where the chrome is gone and

should be replated or replaced.

E. ASSEMBLY AND INSTALLATION (Fig. 17)

1. Assembly of the cylinder is in reverse of order in

which it was disassembled. Lubricate all parts during

assembly.

2. Install the base in its original position, being

careful not to damage the O-ring and back-up ring.

3. Pour two pints of hydraulic oil with rust inhibitor

additive into the cavity between the primary and

secondary rods, before screwing the bushing into the top

of the primary rod.

Figure 18.

4. After the cylinder is installed, adjust the load

chains.

B-179

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |