|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

UPRIGHTS

A. GENERAL

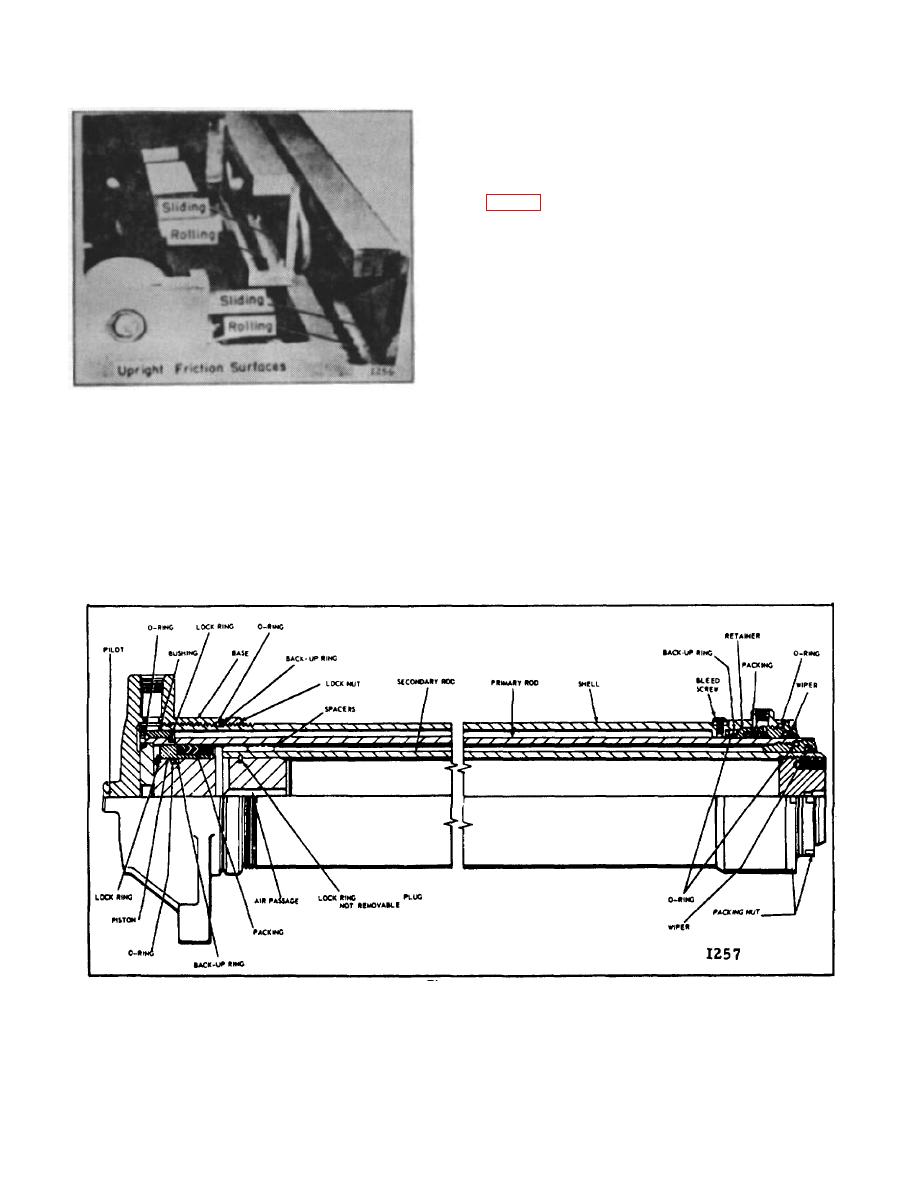

The three-stage hoist cylinder used on the free lift and

three-stage uprights is made up of four components: (1)

Shell, (2) Primary Rod, (3) Secondary Rod, (4) Base.

The shell is threaded at both ends. A packing nut is

screwed into the internal threads at the top and the base

is screwed onto the external threads at the bottom.

Relationship between base and shell is secured by a

lock nut. Located near the top of the shell is a bleed

screw and a leak-off fitting.

A bushing secured to the bottom of the primary rod and

a packing nut at the top centers the rod in the shell.

Self-adjusting packing at the top of the cylinder provides

Figure 16.

the necessary high pressure seal between the primary

rod and outer shell.

of the uprights.

Also, higher than normal hydraulic

pressure will be needed to lift a given load.

The secondary rod is centered in the primary rod by a

self-adjusting packing assembly secured to the bottom

F. INSTALLATION

of the secondary rod and a bushing and seal assembly

screwed into the top of the primary rod.

Reverse removal procedure.

The outside diameters of both rods are chrome plated to

HOIST CYLINDER

retard oxidizing when exposed to the atmosphere.

Figure 17.

B-177

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |