|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

STEERING

axle and thrust washer. Record this measurement to

B. INSPECTION

determine choice of shims when replacing thrust

washers.

1. Thoroughly wash parts and socket shell with

solvent. Examine parts and ball stud for flats, scoring,

3. Remove front and rear bearing caps. (Fig. 2)

galls and excessive wear. Replace parts as necessary.

4. Raise rear of truck sufficiently to allow sliding

C. ASSEMBLY

bearings and thrust washers from the stub shafts. Block

wheels to prevent them from rolling while axle and truck

Assemble parts in the reverse order of removal. Insert

are separated.

lubricated ball stud into socket opening and tighten

adjusting plug until an abrupt resistance to turning effort

B. INSTALLATION

is felt, then back off to nearest lock point and insert

cotter pin.

1. Place bearings, thrust washers and shims in

position on stub shafts. Adjust clearance as close to

MANUAL STEERING GEAR

zero as possible, without binding.

A. GENERAL

2. Guide axle into position while lowering truck.

This is a recirculating ball type unit. In this steering gear

3. Install caps in proper places as indicated by

the steering wheel control forces are transmitted through

marks previously made.

a recirculating ball worm to a rack. In turn the rack

drives the pitman shaft.

BALL SOCKET AND BALL STUD

B. REMOVAL

A. DISASSEMBLY

1. Match mark the pitman arm and shaft. Remove

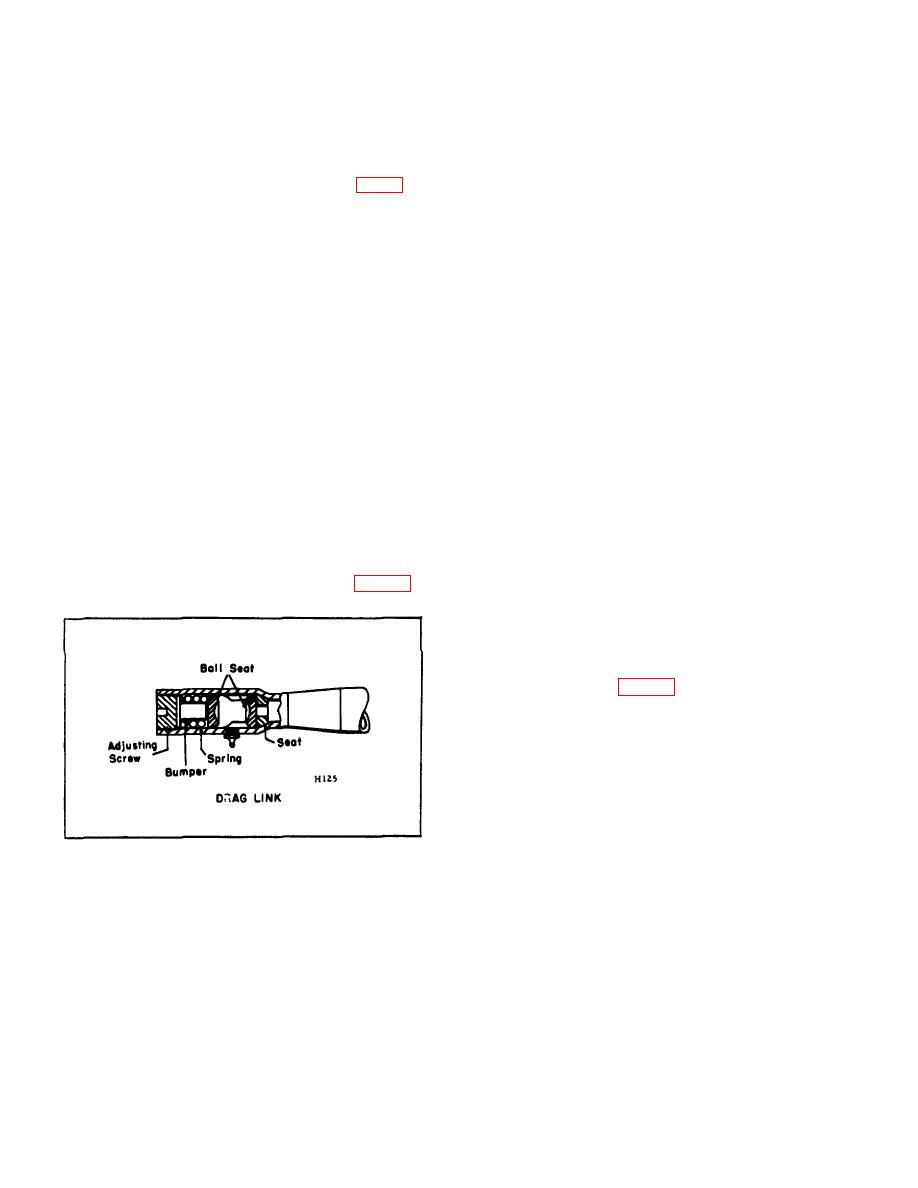

Remove cotter pin and unscrew adjusting screw plug,

the pitman arm from the steering gear pitman shaft.

remove ball stud, seats, spring and bumper. (Fig. 12)

2. Release the column support clamp under the

instrument panel. Disconnect the horn wire.

3. Remove the mounting flange bolts.

C. DISASSEMBLY (Fig. 13)

1. Loosen adjusting screw locknut and remove the

housing side cover by unscrewing adjusting screw.

2. Remove adjusting screw from slot in end of

pitman shaft making certain shim found on adjusting

screw is kept with the screw.

Figure 12.

B-164

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |