|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

BRAKES

3. Remove mounting screws. Then work boot off

the piston rod and pull master cylinder away from the

rod.

C. DISASSEMBLY (Fig. 8)

1. Thoroughly clean outside

of

the

cylinder

assembly, with denatured alcohol.

2. Remove filler cap and gasket, Empty the

reservoir. Remove boot and brake line fitting.

3. Position cylinder in a vise, open end up, so that

the pressure of the vise jaws do not distort the cylinder.

(Note "Caution" below). Using a screwdriver, pry lock

wire from groove in cylinder bore. Internal parts should

then slide from the cylinder in the following order: First

the piston stop followed by the piston cup. Next to be

removed is the piston, followed by the piston spring, and

check valve assembly. The last component to be

removed will be the check valve seat.

The check valve seat is firmly seated into the fitting end

of the cylinder bore and can be extracted either with a

stiff wire hook, or pushed from its seat with stiff wire

inserted into and through the fitting hole.

CAUTION: Internal parts are spring-loaded and may be

released faster than the serviceman's reflexes.

Therefore, personal harm may result from looking

directly into the cylinder bore when removing the lock

wire or attempting to removed a seized component.

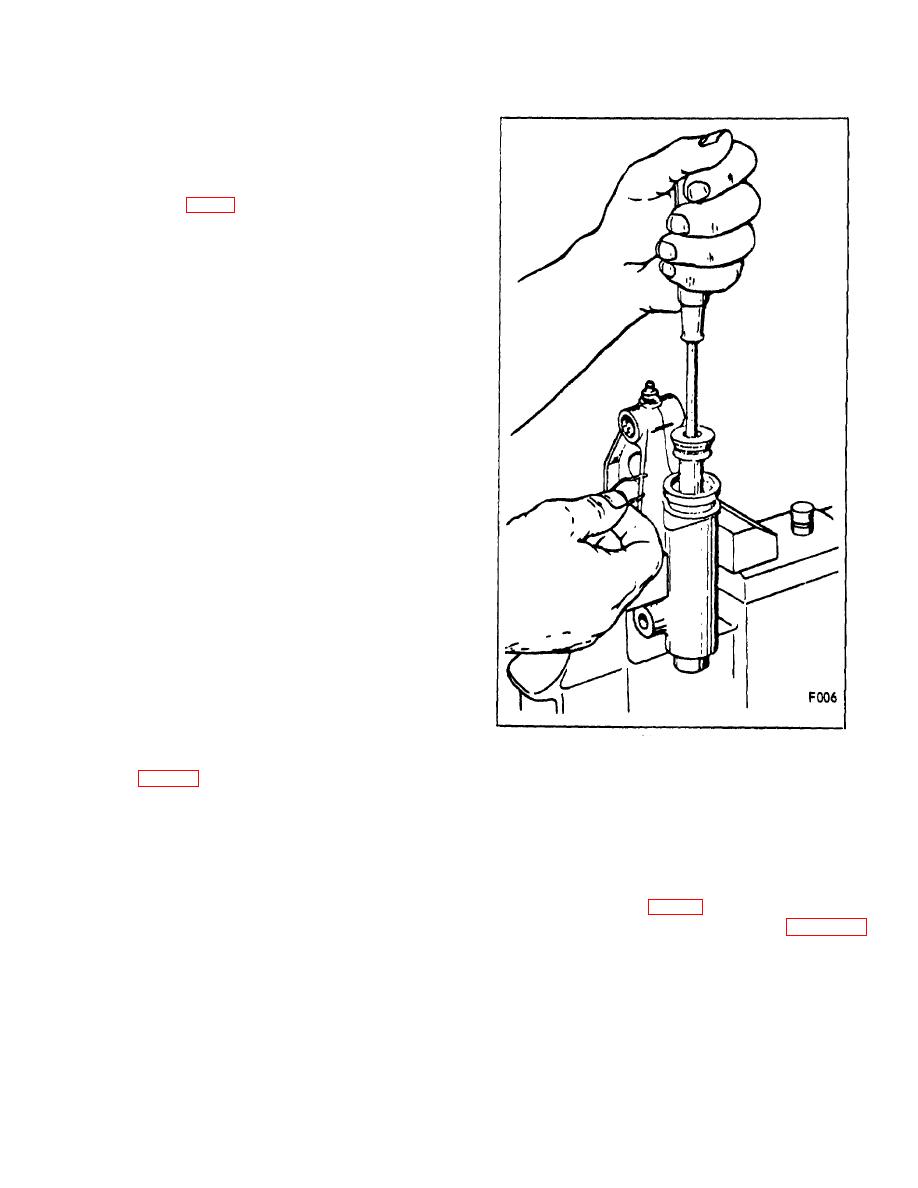

Figure 9.

Free one side of stop, then complete removal as

illustrated In Figure 9,

NOTE: Do not use mineral base solvents to clean

cylinder components, as they will attack and

D. CLEANING AND INSPECTION

deteriorate rubber parts.

1. Clean all parts in denatured alcohol making sure

2. Hold cylinder toward a strong light and sight

there is no trace of dirt, sludge, metal particles, or other

through cylinder bore. Inspect wall for pitting and

foreign materials on or in the cylinder components.

scratches. If any of these or other defects are noticed,

hone the cylinder wall. (Fig. 10)

3. Measure cylinder bore diameter. Figure 11

illustrates checking cylinder with a step-gauge. Discard

cylinder if diameter is

B-133

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |