|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

BRAKES

system at all times, regardless of expansion (heat) or

contraction (cold).

The secondary compensating

function is the replacement of additional fluid into the

system to offset any loss due to seepage.

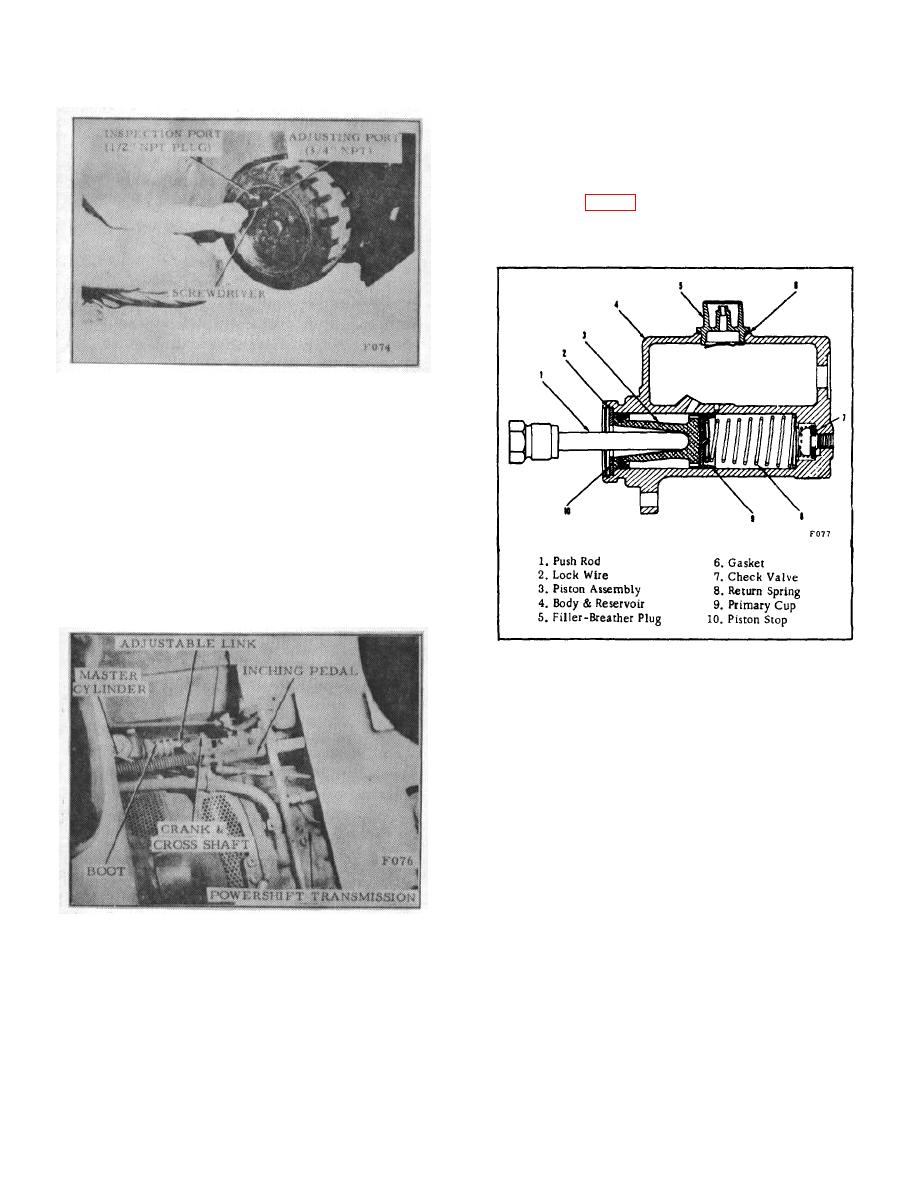

The cylinder (Fig. 8) consists of body and reservoir

casting, double check valve and seat, piston cup return

spring, piston cup, piston, piston stop, boot and push

rod.

Figure 6.

4. Apply the brakes to center the shoes. Check

the shoe-drum relationship, by removing the smaller

plug and viewing through the hole. Readjust the brake,

if necessary.

5. Screw the plugs into the wheels.

Lower the

wheels.

MASTER CYLINDER

A. GENERAL (Fiq. 7)

Figure 8.

The fluid reservoir is cast integral over the master

cylinder body. A combination filler and breather plug is

screwed into the top of the reservoir.

B. REMOVAL

1. Remove floor board and clean master cylinder,

making sure no loose dirt is left in the working area.

2. Disconnect the hydraulic line from the master

cylinder. Plug or tape both openings. A short, machine-

sharpened pencil is a good tool for this purpose.

Figure 7.

Converting mechanical effort into hydraulic pressure is

the main function of the master cylinder, which is of the

compensating type. Its primary compensating function

is to maintain a constant volume of fluid in the hydraulic

B-132

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |