|

|||

|

|

|||

|

Page Title:

FLYWHEEL AND FLYWHEEL HOUSING (Runout) |

|

||

| ||||||||||

|

|

ENGINE

FLYWHEEL AND FLYWHEEL HOUSING (Runout)

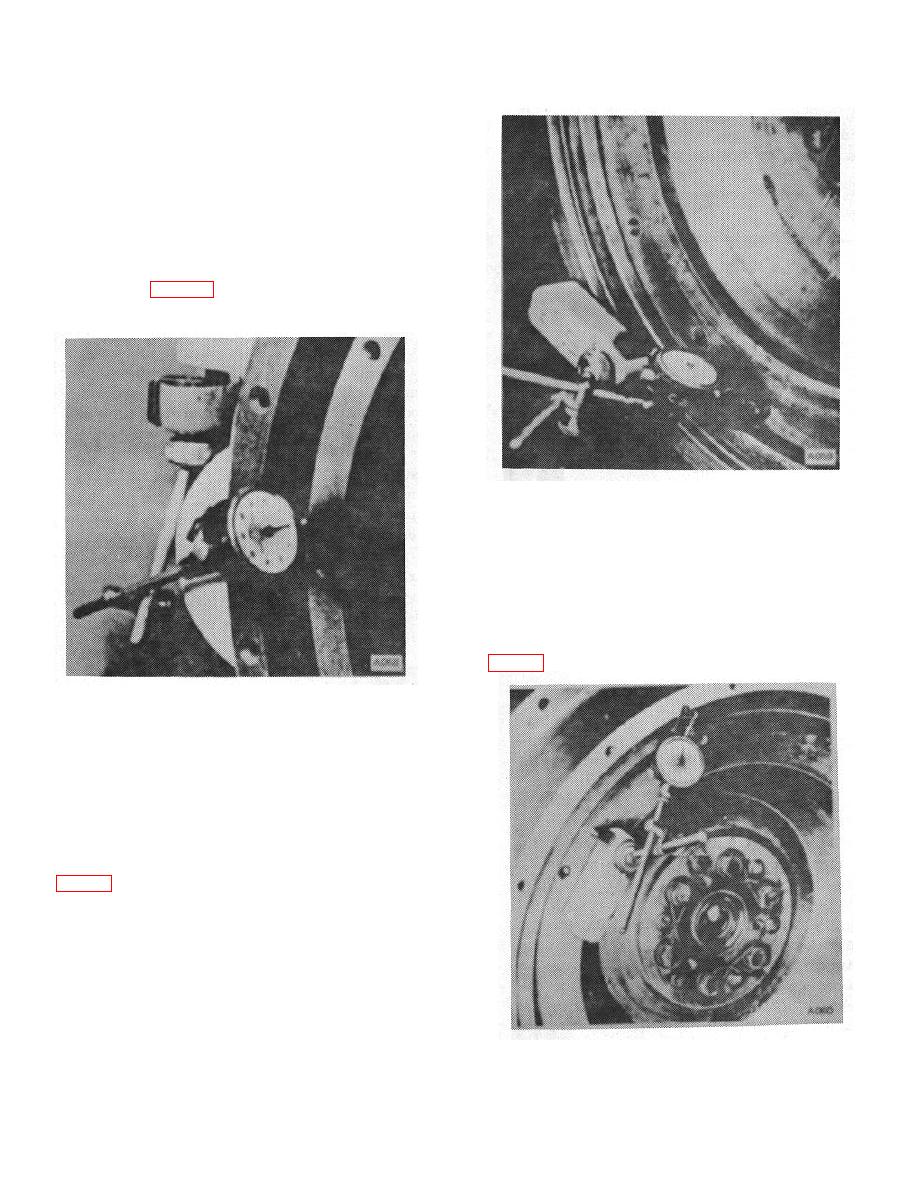

A. FLYWHEEL

1. The flywheel is machined and balanced so that

the clutch face and locating counterbore will run true

with its axis. To be sure that the crankshaft flange, or

the counterbore in the flywheel which locates it on the

crankshaft, has not been sprung or damaged, mount an

indicator on the flywheel housing and check the flywheel

for runout. (Fig. 57) Remove spark plugs before

checking runout to allow free engine turnover.

Figure 58.

B. HOUSING

When assembled, mount the indicator on the flywheel

so that it contacts the housing face and turn the

crankshaft, at the same time holding against it to

counteract end play.

The maximum indicator reading must not exceed .008".

Figure 57.

2. The indicator should be set up so that it contacts

the clutch face on the vertical surface of the clutch

counterbore, then turn the flywheel one full revolution, at

the same time holding against the crankshaft to offset

the possibility of end play. Excessive runout of the

flywheel in either position will probably be caused by dirt

in, or damage to, the counterbore locating the flywheel

on the crankshaft flange. Relocate the indicator to

check the inside diameter of the counterbore.

must not be more than .008".

Figure 59.

B-20

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |