|

|||

|

|

|||

|

Page Title:

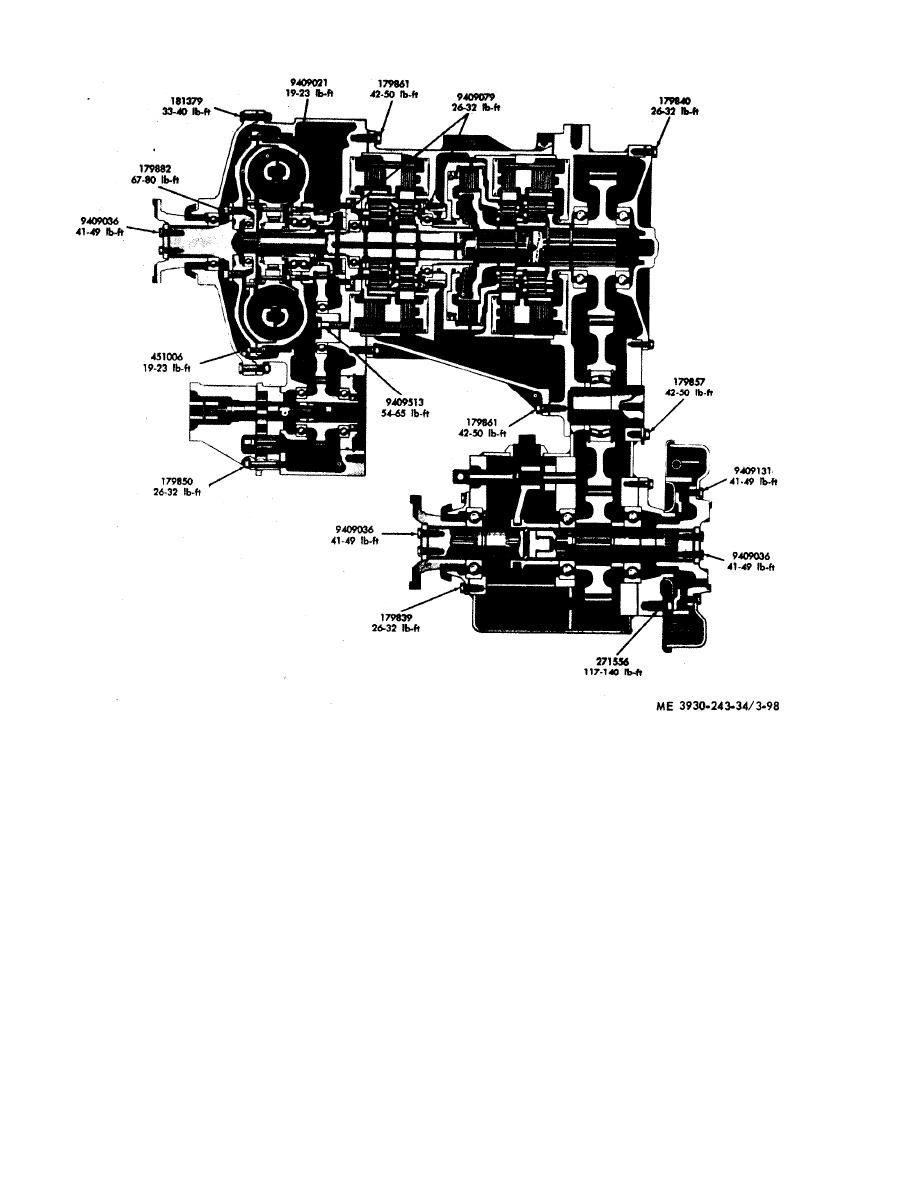

Figure 3-98. Transmission torque valves. |

|

||

| ||||||||||

|

|

operating temperatures (180 to 200 F.) and the

f. Pressure Checking.

engine running at 1,000 rpm.

(1) M a i n p r e s s u r e c h e c k .

g. Linkage Adjustment.

(a) T h e m a i n p r e s s u r e m a y b e c h e c k e d b y

(1) Range selector linkage. T h e l i n k a g e m u s t

the gage on the instrument panel.

be adjusted so that the operator's control is

( b ) The main pressure at full throttle stall

positioned to correspond exactly to the detent

should be approximately 110 to 135 psi.

positions of the range selector valve. With the

(2) Converter-out-pressure check.

l i n k a g e disconnected, place both the selector valve

(a) T h e c o n v e r t e r - o u t - p r e s s u r e m a y b e

and the operator's control in neutral position.

checked at the point provided for attaching the

Adjust the linkage so that it can be freely connected

temperature gage sending unit at the upper left side

w i t h o u t moving the valve or the control. Then try

o f the converter housing.

the control in each range position. Make minor

(b) Maximum converter-out-pressure at full

throttle top speed is 65 psi, with transmission at

adjustments, if necessary, to insure that the selector

valve detent seats at every range position of the

normal operating temperature (180 to 200 F.).

(3) L u b r i c a t i o n o i l p r e s s u r e . The lubrication

operator's control.

o i l p r e s s u r e s h o u l d b e 20 to 25 psi when the

(2) Forward-reverse linkage. The forward and

reverse control linkage must be adjusted so that the

transmission is in low range, forward, with the

output stalled and the transmission at normal

neutral, forward. and reverse detent positions of the

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |