|

|||

|

|

|||

|

Page Title:

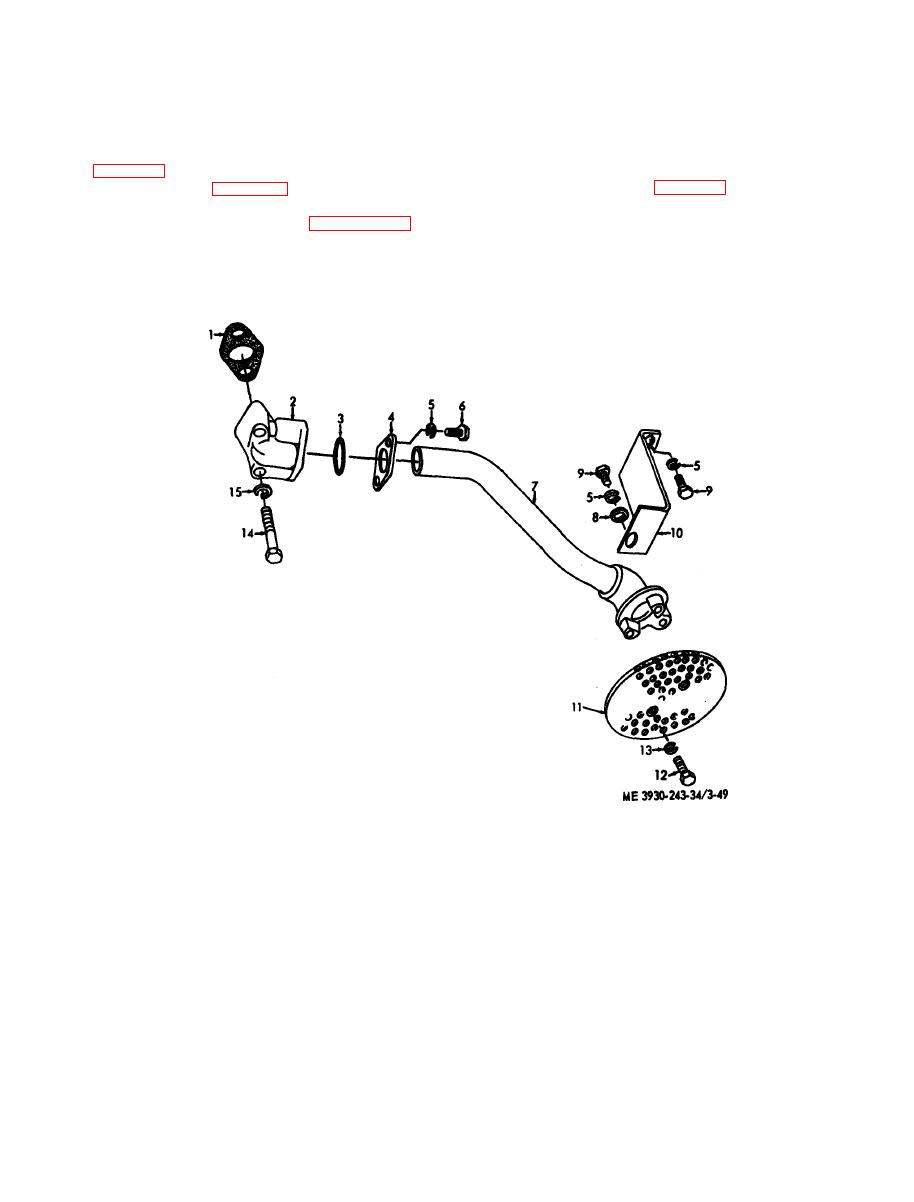

Figure 3-49. Oil pump screen and inlet pipe, disassembly and reassembly. |

|

||

| ||||||||||

|

|

( 2 ) Inspect inlet pipe for deep dents and

formed on the inlet side of the pump and oil is

cracks.

drawn from the crankcase through the oil pump

( 3 ) Inspect mounting hardware and screen

screen and inlet pipe into the rotor compartment of

assembly for damage.

the oil pump.

e. Installation.

b. Removal.

(1) Install inlet pipe and oil pump screen (fig.

(1) Drain the engine oil and remove the oil pan

3-2 B).

(2) Install oil pan (para 3-24).

(2) Refer to figure 3-2B and remove the inlet

( 3 ) Refer to current lubrication o r d e r a n d

pipe and oil pump screen.

service the engine lubrication system.

disassemble the oil pump screen and inlet pipe.

d. Inspection.

(1) Inspect the inlet pipe and screen for

evidence of clogging.

1 Gasket

9 Bolt

10 Support

2 Elbow

11 Screen

3 Ring

12 Screw

4 Flange

13 Washer

5 Washer

14 Bolt

6 Bolt

7 Tube assembly

15 Washer

8 Washer

spray. Each piston is fitted with six piston rings.

Cylinder Liner

Four compression rings are placed above the piston

pin and two, three piece oil-control rings are placed

a. General. The top of the piston forms the

below the pin to scrape off excess oil thrown onto

c o m b u s t i o n chamber bowl and is designed to

the cylinder liner. The connecting rod connects the

compress the air into close proximity to the fuel

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |