|

|||

|

|

|||

|

Page Title:

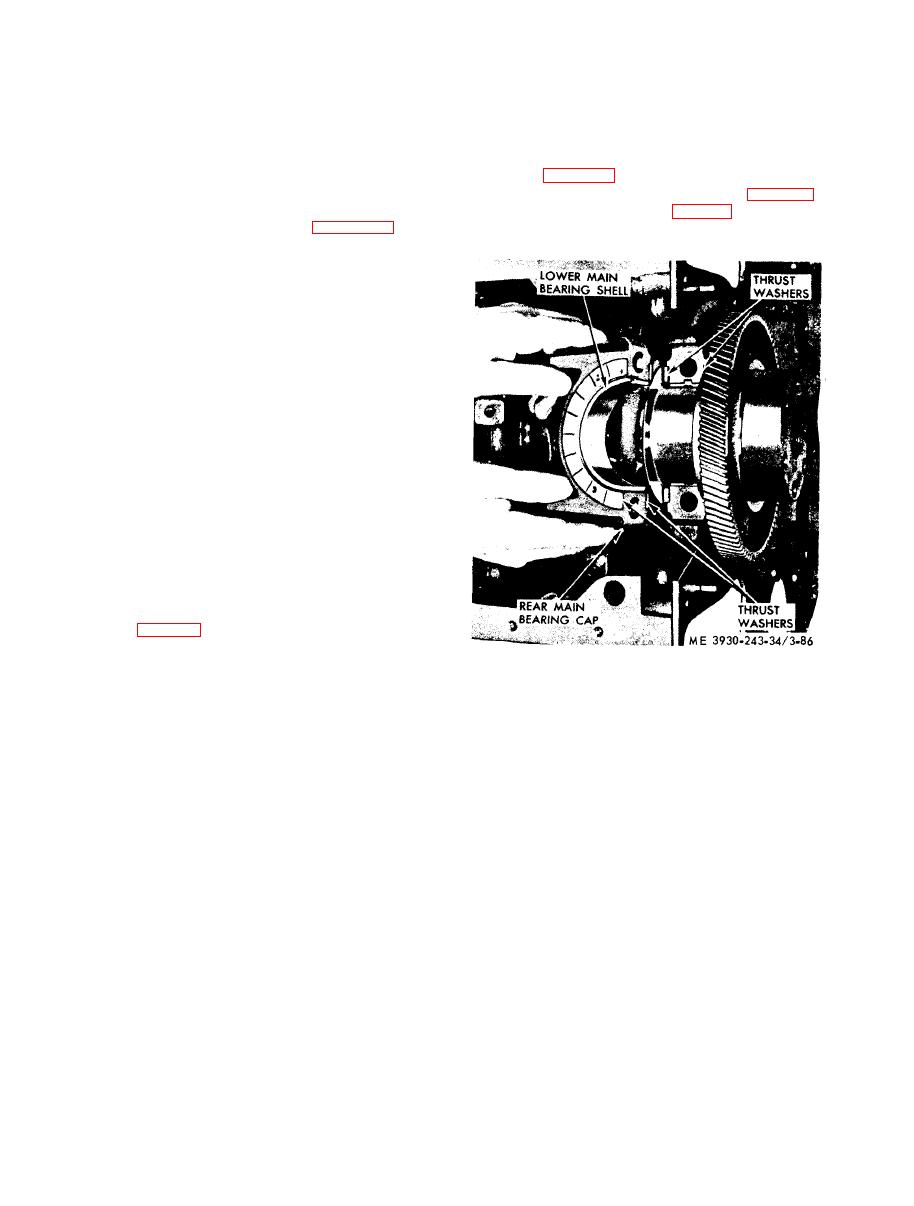

Figure 3-86. Rear main bearing thrust washer and mounting. |

|

||

| ||||||||||

|

|

so that when shell is in place the tang will fit into

NOTE

If end play has increased to the point where clearance

the groove in the shell support.

is in excess of 0.004 to 0.011 inch, new washers

(2) Assemble crankshaft thrust washer before

should be installed.

installing rear main bearing cap. Clean both halves

of thrust washer carefully, removing any burs from

(5) Install lubricating oil pump inlet pipe

the seats-the slightest particle of dirt may decrease

assembly (para 3-25).

clearance between washers and crankshaft beyond

(6) Install oil pan with new gasket (para 3-24).

limits. Slide upper halves of thrust washers into

(7) Install the engine (para 2-9).

place in their grooves, as shown in figure 3-86; then

assemble lower halves over dowel pins in bearing

cap.

NOTE

Main bearing caps are bored in position and marked

1, 2, 3, 4, and 5. They must be replaced in their orig-

inal positions with marked side of caps facing the

same side of cylinder block that carries the engine

serial number.

(3) With the lower main bearing shells in-

stalled in bearing caps, install caps in their original

position and draw bolts up snug. Then tap caps

lightly with a soft hammer to seat them properly,

a n d d r a w b e a r i n g c a p b o l t s uniformly tight,

starting with center cap and working alternately

towards both ends of block, to 120-130 foot-pounds

NOTE

If the bearings have been installed properly. the

crankshaft will turn freely with all main bearing caps

bolted tight.

(4) Check crankshaft end play at thrust

washers (fig. 3-87). This clearance should be from

0.004 to 0.011 inch. Insufficient clearance will

usually denote misalignment of the rear main

bearing. In such case, loosen and retighten the rear

main bearing cap. I f lack of clearance is still

present, dirt on a bur on inner face of one or more

of the thrust washers may be the cause, or washer

may be bent.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |