|

|||

|

|

|||

|

Page Title:

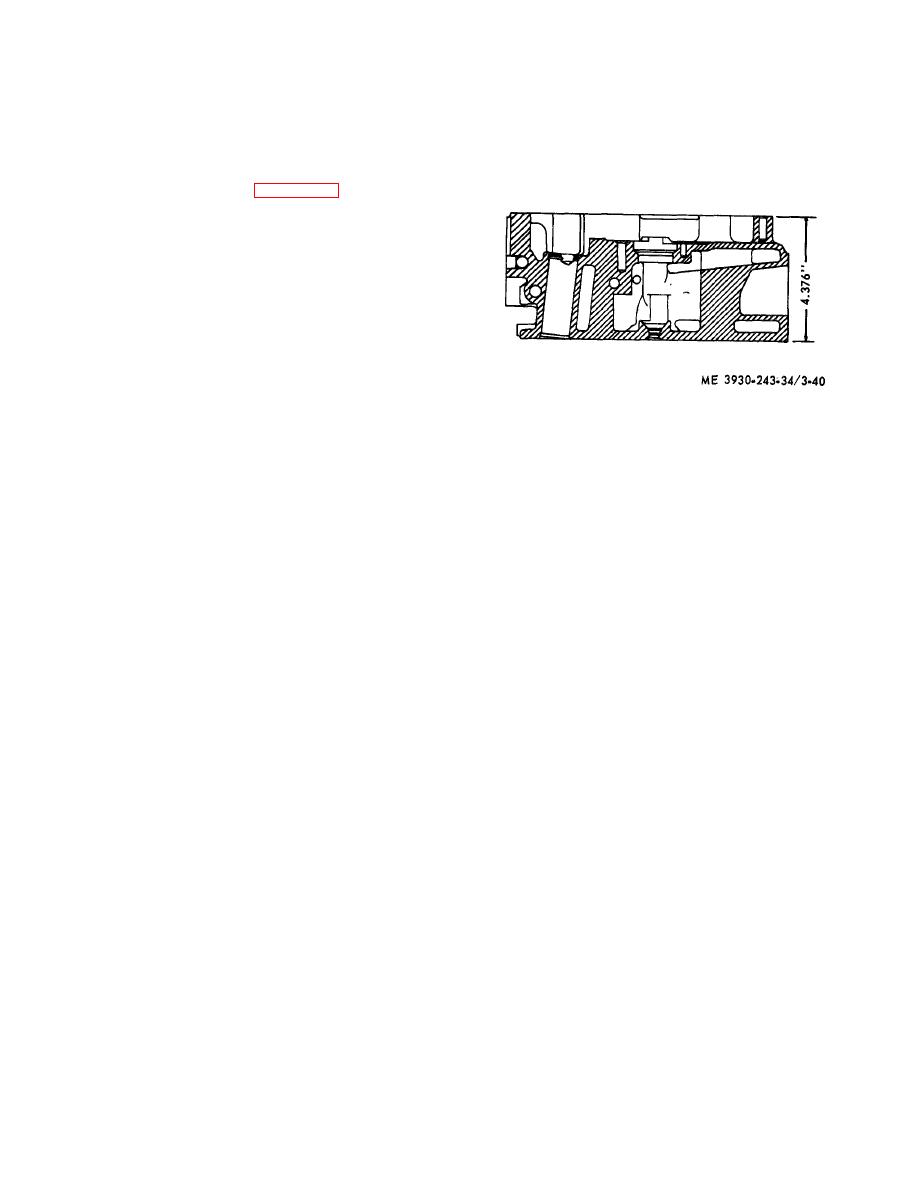

Figure 3-40. Minimum distance between top and bottom faces of cylinder head. |

|

||

| ||||||||||

|

|

head, the amount of stocked removed should be

(c) Press nozzles into place with outlet holes

stamped on the face of the fire deck near the outer

positioned t o w a r d l o n g i t u d i n a l c e n t e r l i n e o f

edge of the head, in an area not used as a sealing

cylinder head. The angle between outlet holes in the

n o z z l e is 90. Nozzles should be from flush to

surface. Not over 0.002 inch of metal should be

1/32 inch below bottom surface of cylinder head,

removed from the fire deck of any cylinder head.

otherwise interference with proper seating of the

The distance from the top deck to the bottom (fire

head on the cylinder may be encountered.

deck) of the cylinder head must not be less than

4.376 inch as shown in figure 3-40. After a cylinder

head has been refaced, and new injector tubes have

been installed, the cylinder head should be

pressured checked. The top surface of the cylinder

block will not warp to the extent that machining

will become necessary, therefore, no warpage limits

or machining limits are required.

(3) Inspect cylinder head for leaks using the

following procedure:

(a) Seal off the waterholes in the head, using

s t e e l plates and suitable rubber gaskets held in

place by bolts.

(b) Install dummy or scrap injectors to

i n s u r e seating of the injector hole tubes. The

dummy injectors may be made up with old injector

of cylinder head.

n u t s and bodies, the injector spray tip is not

e. Assemble Cylinder Head. New service cylinder

necessary. Tighten the injector clamp bolt to 25-30

heads, for replacement purposes, are equipped with

foot-pounds torque.

valve guides, valve seat inserts, exhaust manifold

(c) Apply 80-100 psi air pressure to water

s t u d s , water nozzles, injector hole tubes and

j a c k e t by drilling and tapping into one of the

waterhole cover plates for an air hose connection.

necessary plugs.

Immerse the head in a tank of water previously

CAUTION

heated

to

180-200F.

for

20

minutes

to

When installing the plugs in the fuel

thoroughly heat the cylinder head.

manifolds apply a small amount o f

(d) Observe the water in the tank for bub-

s e a l a n t to thread of plugs only. Work

bles indicating cracks or leaks.

sealant into threads and wipe off excess

w i t h a clean, lint-free cloth so that

(e) Replace any leaking injector hole tubes.

If inspection reveals cracks in the cylinder head, it

sealant will not be washed into the fuel

should be replaced.

system and result in serious damage to

( 4 ) Inspect cam follower bores in cylinder

the injectors. If the old cylinder head is

head for scoring or wear. Light score marks may be

t o be reused, the parts listed below

cleaned up with crocus cloth wet with fuel oil. If

should be installed in the old head prior

bores are excessively scored or worn so that cam

to assembling the head on the cylinder

f o l l o w e r - t o - h e a d clearance exceeds 0.006 inch,

block.

replace the cylinder head.

(1) Install exhaust valves and springs.

(2) Install push rod assemblies, cam followers,

(5) Inspect the valve seat inserts for cracks or

cam follower guides, rocker arm shaft and rocker

burning. Also, check the valve guides for scoring,

arms.

(6) Inspect water nozzles for tightness. Water

n o z z l e s are used only in the passages between

( 3 ) Place new washers on fuel connectors;

then install fuel connectors and tighten to 20-28

cylinders. To install or replace cylinder head water

foot-pounds torque.

nozzles:

(4) Install fuel injectors at this time or after

(a) Be sure water inlet ports in bottom of

installing cylinder head.

head are clean and free of scale. Water holes may

f. Preinstallation I n s p e c t i o n . The following

be cleaned up with a 5/8 inch diameter drill. Break

inspections should be made just prior to installing

the edges of the holes slightly.

the cylinder head on the engine. These inspections

(b) Check for press fit of nozzles in cylinder

s h o u l d be made whether the head was removed

head. If water holes in head have been enlarged by

f r o m the engine for servicing only the head

corrosion, use wooden plug or other suitable tool to

assembly, or to facilitate other repairs to the engine.

expand nozzle, so that they will remain tight after

installation.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |