|

|||

|

|

|||

|

Page Title:

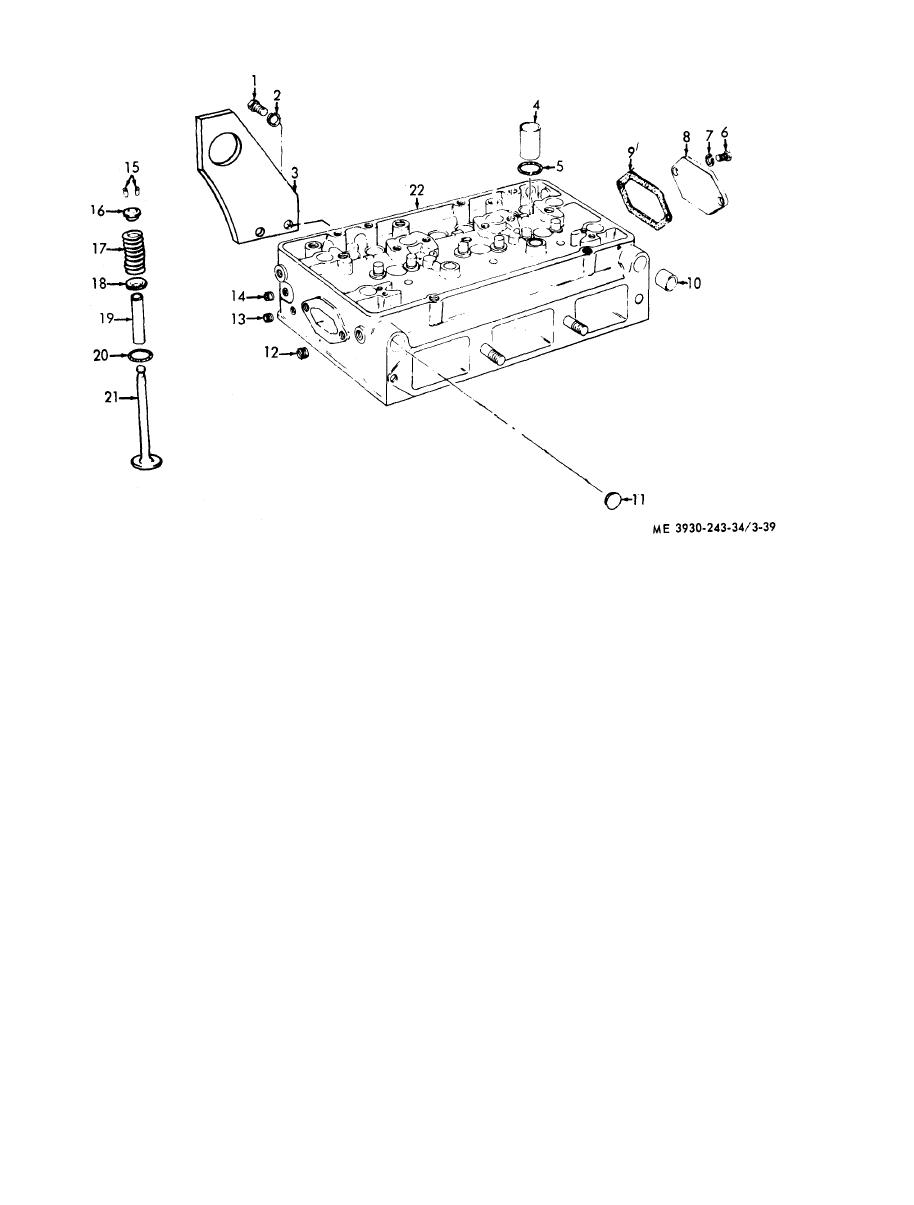

Figure 3-39. Cylinder head and valve assembly, disassembly and reassembly. |

|

||

| ||||||||||

|

|

1

Bolt

12

Plug

2

Lockwasher

13

Plug

3

Bracket

14

Plug

4

Tube

15

Lock

5

Seal

16

Seat

6

Screw

17

Spring

7

Washer

18

Seat

8

Cover

19

Guide

9

Gasket

20

Seat

10

Plug

21

Valve

11

Plug

22

Cylinder head

d. Inspection.

(a) Using an accurate straightedge and

( 1 ) After the cylinder head has been stripped

feeler gage, check for transverse warpage at each

of all component parts it should be thoroughly

end and between all cylinders.

s t r a i n e d clean. Remove all rust proofing compound

(b) Check longitudinal warpage in six

f r o m a service cylinder head. A simple method of

places. Maximum allowable warpage is given

removing the rust proofing compound is to immerse

below.

the head in P-D-680 solvent, oleum, or fuel oil and

M a x i m u m Longitudinal

M a x i m u m Transverse

clean with a soft bristle brush.

Warpage

Warpage

( 2 ) Over a prolonged period of operation, the

0.005 inch

0 . 0 0 4 inch

c y l i n d e r head may assume a contour to match that

of the cylinder block, which is normal. However, if

The maximum allowable warpage limits should be

t h e cylinder head is allowed to become overheated

u s e d as a guide in determining the advisability of

because of coolant loss, the resultant high tem-

r e i n s t a l l i n g the head on the engine or refacing it,

perature cause stresses to occur in the casting which

The number of times a cylinder head may be

w i l l affect the flatness of the head. Therefore, the

r e f a c e d will, of course, depend upon the amount of

b o t t o m (fire deck) of the cylinder head should be

stock removed from the head during previous

checked for flatness as follows:

reworking operations. When refacing a cylinder

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |