|

|||

|

|

|||

|

Page Title:

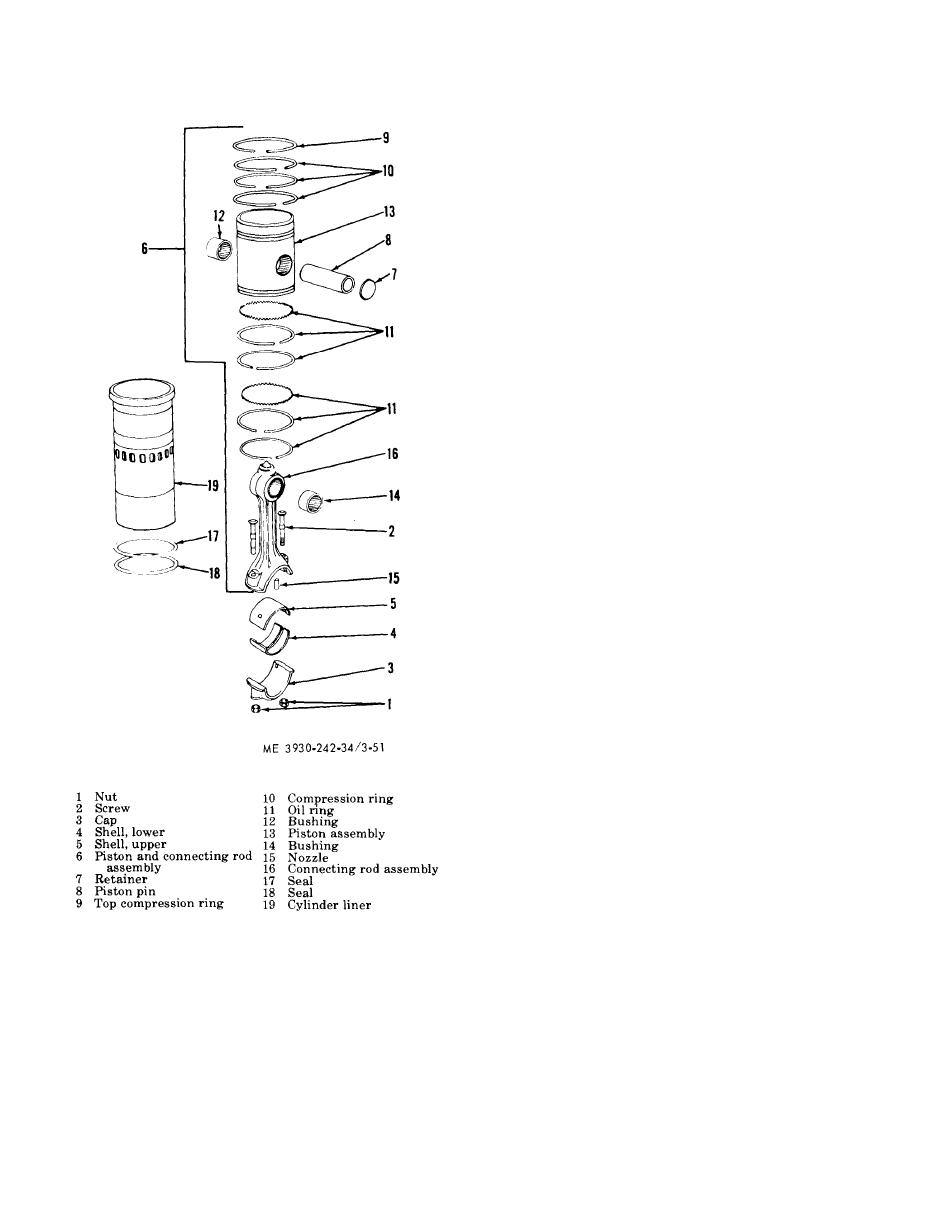

Piston, rings, connecting rod, and cylinder liner, disassembly and reassembly, |

|

||

| ||||||||||

|

|

TM 10-3930-242-34

nance will reduce to a minimum the amount of

a b r a s i v e dust and foreign material introduced

i n t o the cylinder and will, in turn, reduce the

rate of wear.

(c) The protective coating on the skirt of

the piston is from 0.0007- to 0.0015-inch thick.

T h e presence of this coating of tin will, there-

fore, indicate very little wear. A careful exami-

nation of the piston should be made for scoring,

burning, worn or damaged ring grooves and

c r a c k s inside the piston across the struts. A

badly scored piston should not be reused,

whereas a piston only slightly scored may be

c l e a n e d up and reused.

(d) Examine the inside of the piston

c l o s e l y for cracks across the struts and discard

p i s t o n if such cracks are present.

(e) Inspect the top of the piston crown for

burned spots or other indications of overheating

s u c h as carbon formation on the underside of

the piston.

(f) Inspect the piston rings for free fit in

t h e grooves and side clearance.

(g) I n s p e c t a n d m e a s u r e t h e i n s i d e

diameter of the piston pin bushings in each pis-

t o n , and, if worn excessively, replace the bush-

ings or piston assemblies. Also inspect and

measure the piston pin. The standard inside

diameter of bushings in a piston is 1.3775-1.3780

inches and the standard outside diameter of the

piston pin is 1.3746-1.3750 inch. Thus, the stan-

dard clearance between the piston pin and bush-

ing, in a piston is 0.00250.0034 inch with a max-

imum allowable wear limit of 0.010 inch.

(h) The piston taper must not exceed

0.0005 inch from 7/16 inch below the bottom com-

p r e s s i o n ring to the lower end of piston skirt.

T h e diameter of a new standard piston below

t h e compression ring grooves to bottom of pis-

ton skirt is 3.8693-3.8715 inch.

(i) C h e c k t h e p i s t o n - t o - l i n e r c l e a r a n c e

while the piston is held upside down in the liner.

T h e liner should be in place in the cylinder

b l o c k . This clearance should always be checked

when installing either new or used positions and

liners. The clearance of a piston in a liner may

b e checked with liner in the cylinder block, by

i n s e r t i n g a -inch-wide feeler ribbon about 15

i n c h e s long between the piston and liner, then

liner, disassembly and reassembly,

w i t h d r a w feeler ribbon, measuring the force re-

quired with a spring scale. This force should not

Excessively worn or scored pistons, rings and

e x c e e d six pounds. When this force is approxi-

c y l i n d e r liners indicate abnormal maintenance

m a t e l y 6 pounds, the actual clearance between

or operating conditions that should be corrected

t h e piston and the liner is 0.001 inch greater

as quickly as possible. Proper types of lubricat-

than the thickness of the feeler ribbon used.

ing oil filters and air cleaners and their mainte-

F e e l e r ribbon used for checking this clearance

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |