|

|||

|

|

|||

|

Page Title:

Section IV. OIL PAN, OIL PUMP SCREEN, INLET PIPE, CONNECTING RODS AND PISTONS |

|

||

| ||||||||||

|

|

TM 10-3930-242-34

Section IV. OIL PAN, OIL PUMP SCREEN, INLET PIPE,

CONNECTING RODS AND PISTONS

3 - 2 3 . General

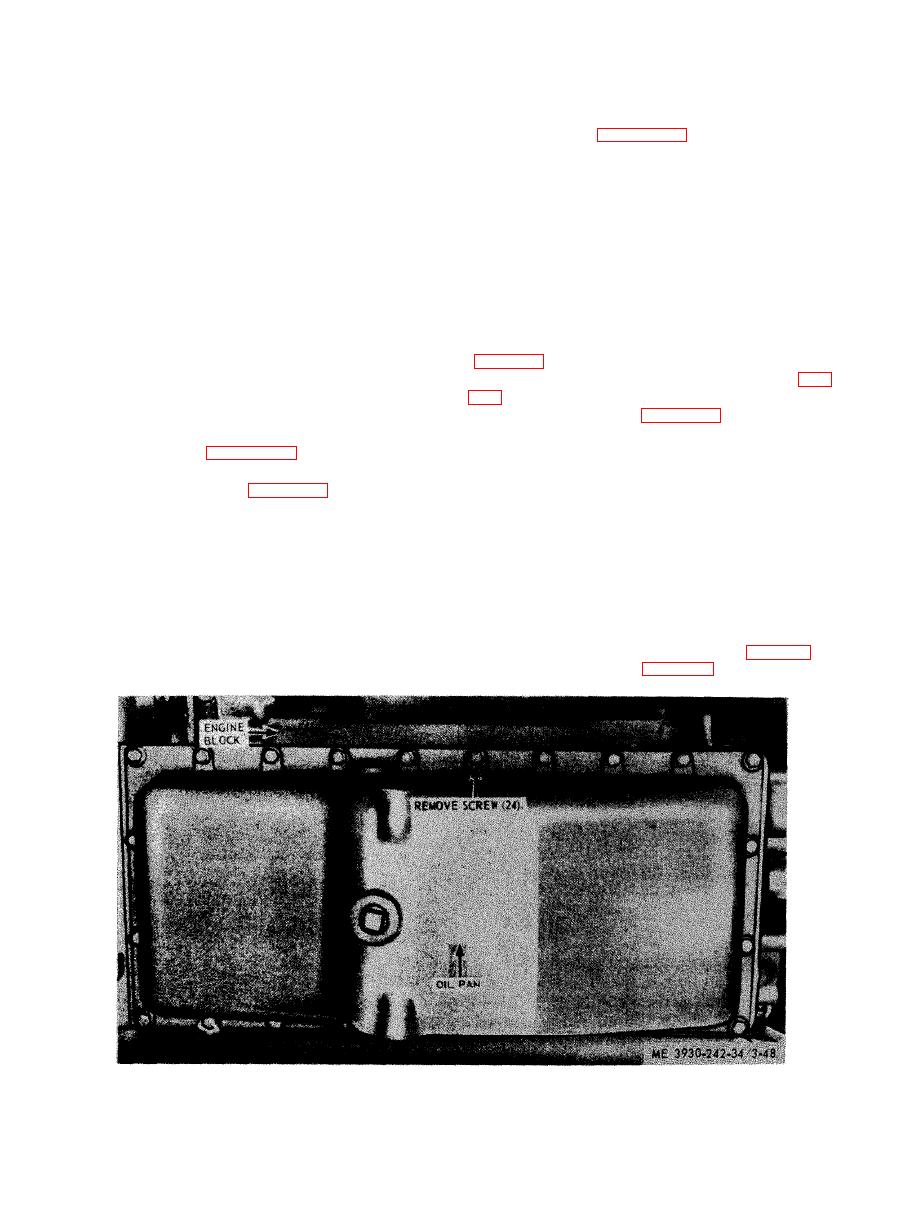

(2) Refer to figure 3-48 and reinstall the oil

pan.

The oil pan houses the lower engine compo-

( 3 ) Refer to the lubrication order and ser-

n e n t s and also contains lubricating oil for the

v i c e engine lubrication system.

e n g i n e . The oil pump screen is secured to the

main bearing cap with two bolts and lock-

w a s h e r s . The inlet pipe is secured to the oil

a. General. As the oil pump rotors revolve, a

pump. The pistons are secured to the connecting

vacuum is formed on the inlet side of the pump

r o d s with wrist pins and connecting rods and

a n d oil is drawn from the crankcase, through

bearings mounted around the crankshaft.

the oil pump screen and inlet pipe, into the rotor

3 - 2 4 . Oil Pan

c o m p a r t m e n t of the pump.

b. Removal.

a. General. The oil pan is secured to the bot-

(1) Drain engine oil and remove oil pan

t o m side of the engine block by 24 bolts and

washers, A drain plug is located in bottom of oil

( 2 ) Remove oil screen and inlet pipe (fig.

pan for draining engine oil, at oil change inter-

vals or for oil pan removal.

b. Removal.

a s s e m b l e oil pump screen and inlet pipe.

(1) Remove plug and drain the engine oil.

(2) Refer to figure 3-48 and remove the oil

d. Cleaning and Inspection.

pan.

(1) Clean all metal parts thoroughly, using

s o l v e n t P-D-080, or equal.

a s s e m b l e the oil pan.

( 2 ) Inspect the inlet pipe for evidence of

d. Cleaning and Inspection.

clogging.

(1) Clean oil pan and attaching hardware,

(3) Inspect the inlet pipe for deep dents and

t h o r o u g h l y using solvent P-D-080, or equal.

cracks.

(2) Remove all gasket material from the

(4) Inspect mounting hardware and the

g a s k e t area.

s c r e e n assembly for damage.

(3) Inspect the oil pan for cracks, excessive

( 5 ) Replace all defective parts.

d e n t s , or other damage.

e. Installation.

e. Installation.

(1) Install inlet pipe and screen (fig. 3-50).

(1) Affix a new gasket to oil pan.

(2) Install oil pan (para 3-24).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |