|

|||

|

|

|||

|

Page Title:

Section XVIII. MAINTENANCE OF HYDRAULIC LIFT, PUMP, AND TUBING |

|

||

| ||||||||||

|

|

TM10-3930-242-12

Section XVIII. MAINTENANCE OF HYDRAULIC LIFT, PUMP, AND TUBING

CAUTION

When removing any hydraulic hoses and

Inspect the cylinder piston end for wear. Inspect

lines, cap all openings to prevent foreign

cylinder for cracks or leaks. If defective, report to

material from entering system, causing

direct support maintenance.

serious damage to the system.

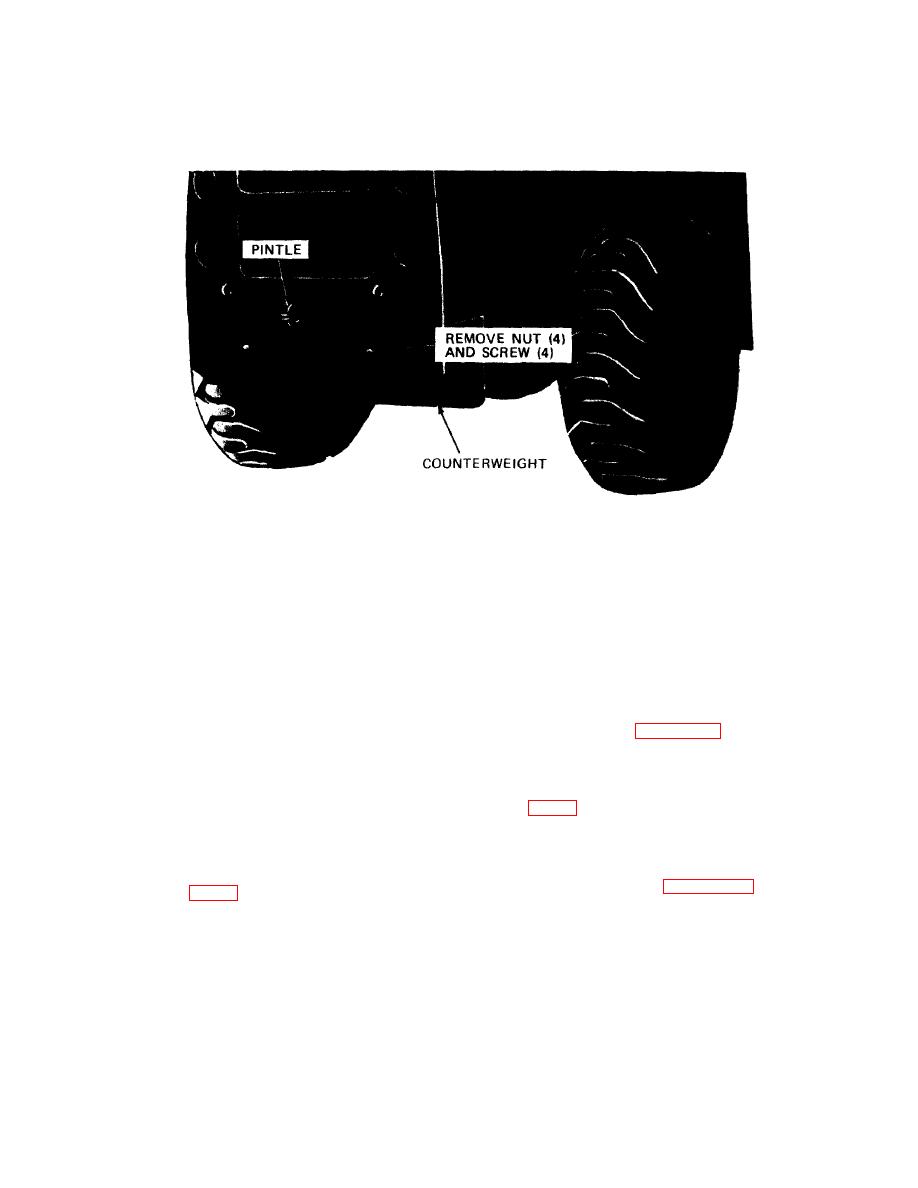

4-73. Fork Carriage

NOTE

Late model rough terrain forklift trucks

fork carriage.

are equipped with a filter contaminator

indicator. This indicator is mounted on

b. Cleaning and Inspection.

the top of the reservoir. Its purpose is to

(1) Clean the carriage with drycleaning solvent

signal when the main hydraulic oil filter is

(item 1, App F).

in "by-pass" and is no longer serviceable.

(2) Inspect the fork carriage for breaks or

cracks in the welding. Inspect pins for wear. Replace

all defective mounting hardware.

a. Cleaning. Clean the cylinder with drycleaning

solvent (item 1, App F).

the fork carriage.

b. Inspection. Inspect for cracks, breaks, ex-

cessive wear, or loose or missing hardware. Inspect

the hoses for deterioration and cuts. Replace all

defective parts.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |