|

|||

|

|

|||

|

Page Title:

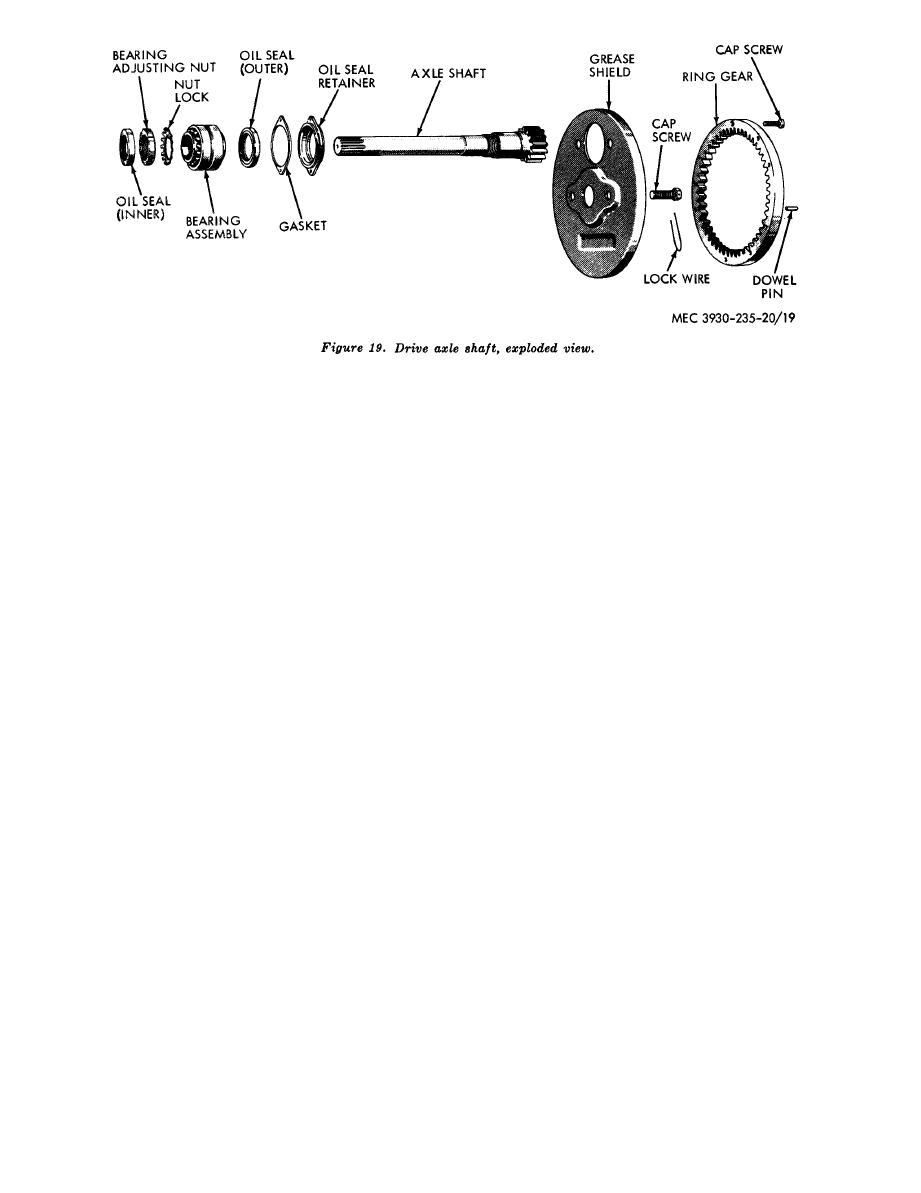

Figure 19. Drive axle shaft, exploded view |

|

||

| ||||||||||

|

|

(4) If necessary, remove inner oil seal

scratches or scars using a fine emery paper,

then polish with emery cloth. If axle shaft

from axle housing using a suitable

surface will not clean up to a fairly smooth

puller.

finish, replace axle shaft.

(5) Repeat above procedures for other

side of truck if necessary.

e. Reassembly.

b. Disassembly.

(1) Reverse procedure in b above.

(1) Straighten ears of nut lock, then un-

(2) Tighten bearing adjusting nut until

screw and remove bearing adjusting

axle shaft binds when turned, then

nut and lock.

back off nut one-sixth turn, or until

(2) Remove bearing assembly, and oil seal

axle shaft turns without binding.

retainer assembly.

f. Installation. Reverse procedures in a

(3) If necessary, remove oil seal from re-

above, except that if gaskets were damaged or

tainer.

lost, it will be necessary to measure the gap

c. Inspection.

between the bearing retainer and the axle hous-

(1) Inspect bearing cones and cup for

ing. Refer to g below for adjustment of axle

scoring, nicks, or flat spots. If there

shaft.

is evidence of bearing cone or cup

g. Adjustment of Axle Shaft. To determine

wear, the bearing assembly must be

the amount of gaskets required to fill the gap

replaced as a complete assembly.

between the bearing retainer and the axle hous-

(2) Inspect axle shaft for chipped or

ing, install the axle shaft assembly in the axle

broken teeth or splines, and oil seal

housing without gaskets. Measure the clearance

ring surfaces for scratched or scarred

between bearing retainer and axle housing with

conditions.

a flat feeler gage. Select gasket thicknesses

d. Repair. If axle shaft oil seal bearing sur-

totaling 0.001 to 0.005 inch less than the meas-

faces are scratched or scarred, remove

ured gap dimension.

AGO 6217A

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |