|

|||

|

|

|||

|

Page Title:

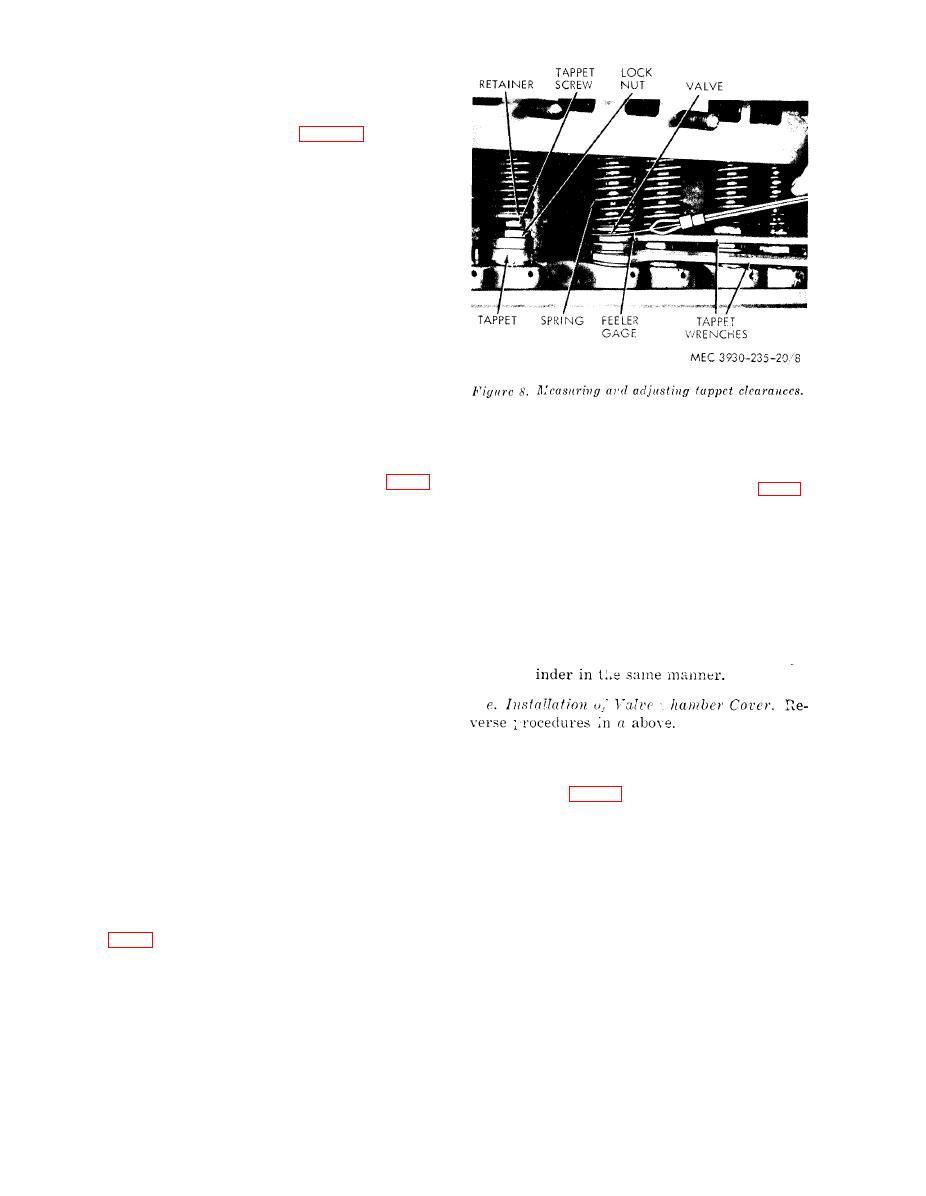

figure 8. measuring and adjusting tappet clearances |

|

||

| ||||||||||

|

|

c. Installation.

(1) Reverse procedures in a above using a

new head gasket.

(2) Tighten the cylinder head nuts in the

sequence shown in figure 7 to a torque

value of 60 to 65 foot-pounds.

Note. Tighten nuts in the proper sequence

to about one-half the required torque value

for the first tightening. At the second tight-

ening bring torque value up to the required

foot-pounds.

(3) Start engine, inspect for leaks and

observe e n g i n e performance. Re-

tighten cylinder head nuts when en-

gine is hot.

22. Valves

Correct valve clearance settings prolong en-

gine life and aid performance. Excessive clear-

ances will disturb timing and will harm cam-

shaft and tappets. Insufficient clearances will

compression stroke. Both valves of

also disturb timing and possibly cause burned

No. 1 cylinder will be closed at this

valves. Correct valve clearance for both intake

position.

and exhaust valves is 0.014 inch hot (fig. 8).

(2) With a 0.014-inch feeler gage (fig. 8)

check clearance between adjusting

a. Removal of Valve Chamber Covers (figs.

screw and roto cap on each va!ve.

8 and 10).

(3) To adjust each valve to proper clear-

(1) Disconnect air cleaner hose from air

ance of 0.014 inch hot, hold the valve

cleaner and carburetor.

lifter assembly firmly with wrench,

(2) Disconnect choke cable and throttle

arid with another wrench, turn adjust-

linkage at carburetor.

ing screw until desired clearance is

(3) Disconnect fuel line at carburetor.

obtained.

(4) Remove two mounting nuts and wash-

(4) Adjust remaining valves for each cyl-

ers, then remove carburetor and

gasket.

(5) Remove two barrel nuts and gaskets,

then remove valve cover and valve

cover gasket. Remove baffles.

22. Intake and Exhaust Manifold

b. Cleaning of Valve Chamber Cover. Clean

cover with SD. Use new gasket when installing

cover.

(1) Connect air cleaner hose from car-

buretor.

c. Inspection of Valve Springs, Locks, and

Seats. Inspect valve springs, locks, and seats

(2) Disconnect choke cable and throttle

for alignment, for cracks, and proper seating.

linkage from carburetor.

Check for weak springs.

(3) Disconnect fuel line at carburetor.

d. Adjustment of Intake and Exhaust Valves

(4) Remove mounting nuts and washers,

then remove carburetor and gasket.

(1) Remove spark plugs and rotate engine

(5) Loosen clamp that attaches muffler to

until No. 1 piston is at TDC on its

frame.

AGO 6217A

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |