|

|||

|

|

|||

|

Page Title:

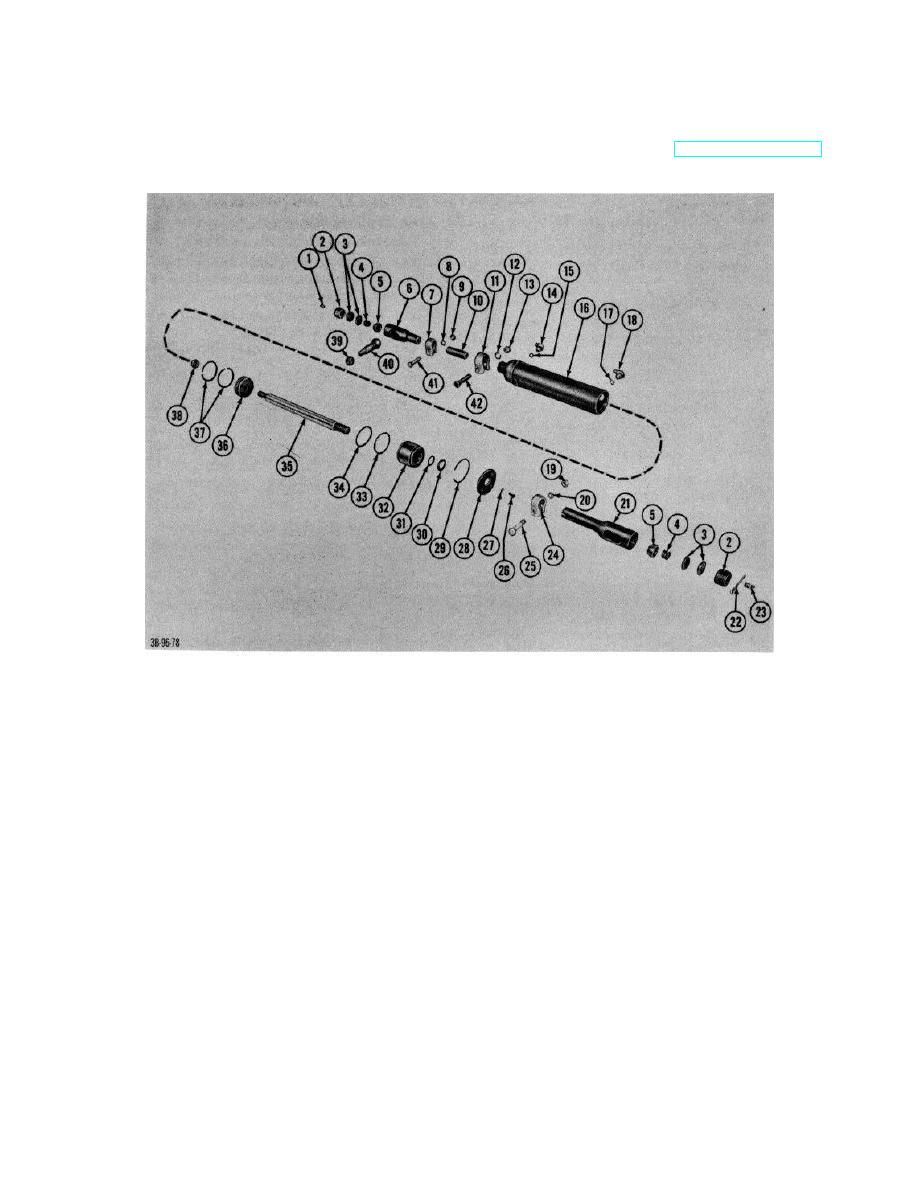

Figure 90. Steering booster cylinder, exploded view. |

|

||

| ||||||||||

|

|

(5) Inspect packing and rings for wear.

c.

Cleaning and Inspection.

d. Assembly. Reverse procedure in b above using

(1) Clean all parts in SD.

new packing, seal, and rings. Lubricate all parts with

(2) Inspect inside of cylinder shell for burs and

hydraulic fluid.

scratches.

e. Installation. Refer to TM 10-3930-222-20.

(3) Inspect piston for nicks and burs.

(4) Inspect piston rod for straightness.

1

Fitting, lubrication

22

Pin, cotter

2

Plugs end

23

Fitting, lubrication

3

Seat ball

24

Clamp

4

Springs

25

Bolt

5

Seats

26

Screw

6

Socket assembly, ball

27

Lockwahser

7

Clamp

28

Plate, end

8

Lockwasher

29

Lockring

9

Nut

30

Seal

10

Stud

31

Packing, preformed, inner

11

Clamp

32

Bearing

12

Lockwasher

33

Packing, preformer, outer

13

Nut

34

Ring backup

14

Elbow, tube fitting

35

Rod

15

Packing, preformed

36

Piston

16

Shell, cylinder, piston

37

Rings, piston

17

Packing, preformed

38

Locknut

18

Elbow, tub fitting

39

Locknut

19

Nut

40

Stud, ball

20

Lockwaher

41

Screw

21

Socket assembly, ball

42

Bolt

Figure 90. Steering booster cylinder, exploded view.

107

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |