|

|||

|

|

|||

|

Page Title:

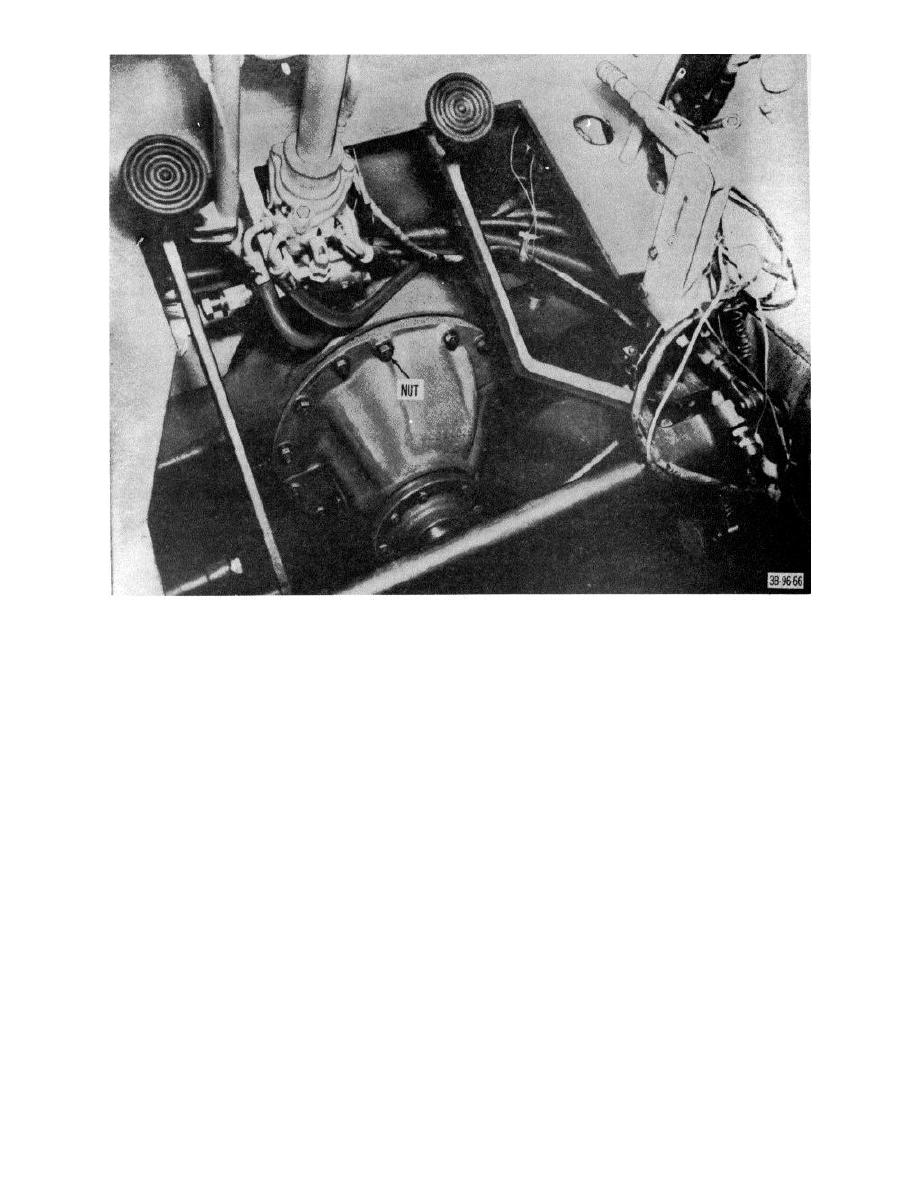

Figure 78. Drive axle and differential and carrier assembly, installed on truck. |

|

||

| ||||||||||

|

|

Figure 78. Drive axle and differential and carrier assembly, installed on truck.

(14) Using new gasket (6), install cover and seal with

(10) While in press under pressure, check bearing

gasket on carrier and cap assembly (19) with

preload torque. Wrap soft wire around cage and

capscrews (26).

pull on horizontal line with pound scale. If a

(15) Install yoke fitting (4) on pinion.

press is not available, the pinion nut (2) may be

(16) Install washer (3) on pinion.

tightened to the correct torque and preload

(17) Install castellated nut (2) on pinion and tighten

checked.

to correct torque (700 foot-pounds) and secure

(11) If rotating torque is not within 12 to 18 inch-

with cotter pin (1).

pounds, use a thinner spacer to increase

preload or a thicker spacer to decrease preload.

Note.

When it is necessary to

(12) Install pinion and cage assembly with shim (12)

replace either the pinion or ring gear, the

into carrier and cap assembly (19) making

gear sat must be replaced. When a new ring

certain that the oil passage holes are alined.

gear or differential case installed, the

(13) Coat outer edge of oil seal (7) with sealing

differential case hole must be line reamed

compound and press seal into cover (5).

with the gear in order to reassemble using

the correct size rivets. Rivets must be upset

cold. The upset head of the rivets should be

one-eighth inch larger in diameter than the

rivet holes.

AGO 7010A

94

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |