|

|||

|

|

|||

|

Page Title:

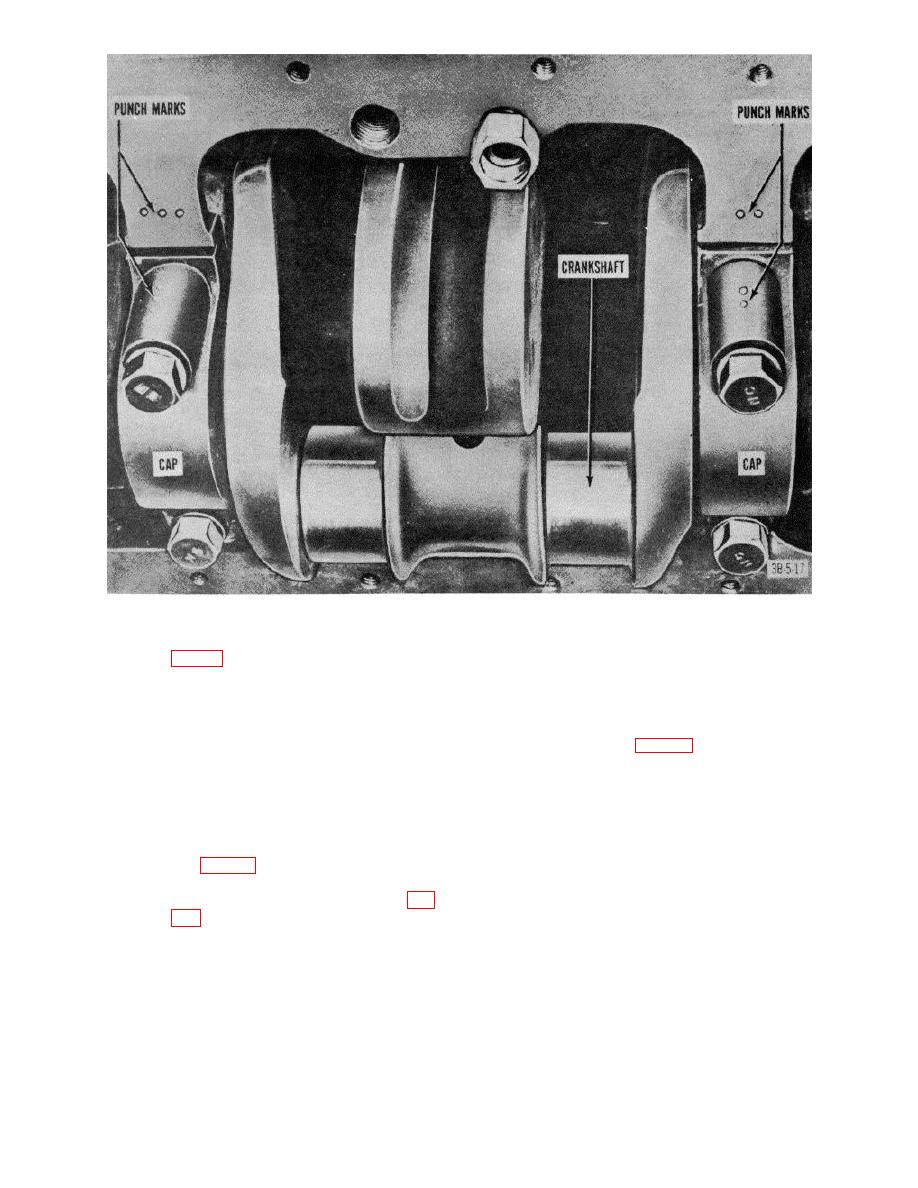

Figure 11. Punch marks on cylinder block and crankshaft bearing caps. |

|

||

| ||||||||||

|

|

Figure 11. Punch marks on cylinder block and crankshaft bearing caps.

specifications Check clearance by

(8)

Remove piston pin retaining rings (8,

inserting a well oiled brass shim (1/2

inch wide by 1 inch long by 0.002 inch

pins (25) from connecting rods and

thick)

between

bearings

and

crankshaft journals.

Using a

b. Inspection and Repair.

torque wrench, tighten cap bolt nuts

(1) Clean all parts with SD.

(18, fig. 10) to 85 to 40 pound-feet of

(2) Inspect for pitting, scoring, or excessive

pressure, and rotate crankshaft. If

wear of connecting rod sleeve

there i stiff resistance while the

bearing.

crnilrh-ft is turning, the bearing

(3) Check alinement of each connecting rod

clearance is not excessive.

with a rod lining fixture and straighten

each connecting rod with arbor press

certain that connecting rod bearing seats are clean.

or connecting rod straightening tool

(B, fig. 13), as necessary, to bring

Coat connecting rod bearings with OE and make certain

that bearing lugs engage slots and that oil holes are

upper and lower bores parallel within

alined.

0.002 inch and to remove twist (A, fig.

(4)

Replace bearings if recommended

clearance (0.001 inch) is not within

AGO 7010A

19

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |