|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

an immovable object, or by applying a correctly

adjusted parking brake equipped with good brake

linings. Place the machine in gear and accelerate

e n g i n e to full throttle. Normal stall is 1450 to

1600 RPM.

f. If readings taken are not reasonably close to

those listed above, appropriate repairs/adjustments

should be made. Refer to Engine Tune-Up

Procedures outlined in paragraph 4-37.

4-37. ENGINE TUNE-UP.

Engine tune-up is the orderly and systematic

process of checking the engine and accessory

equipment to maintain or restore satisfactory

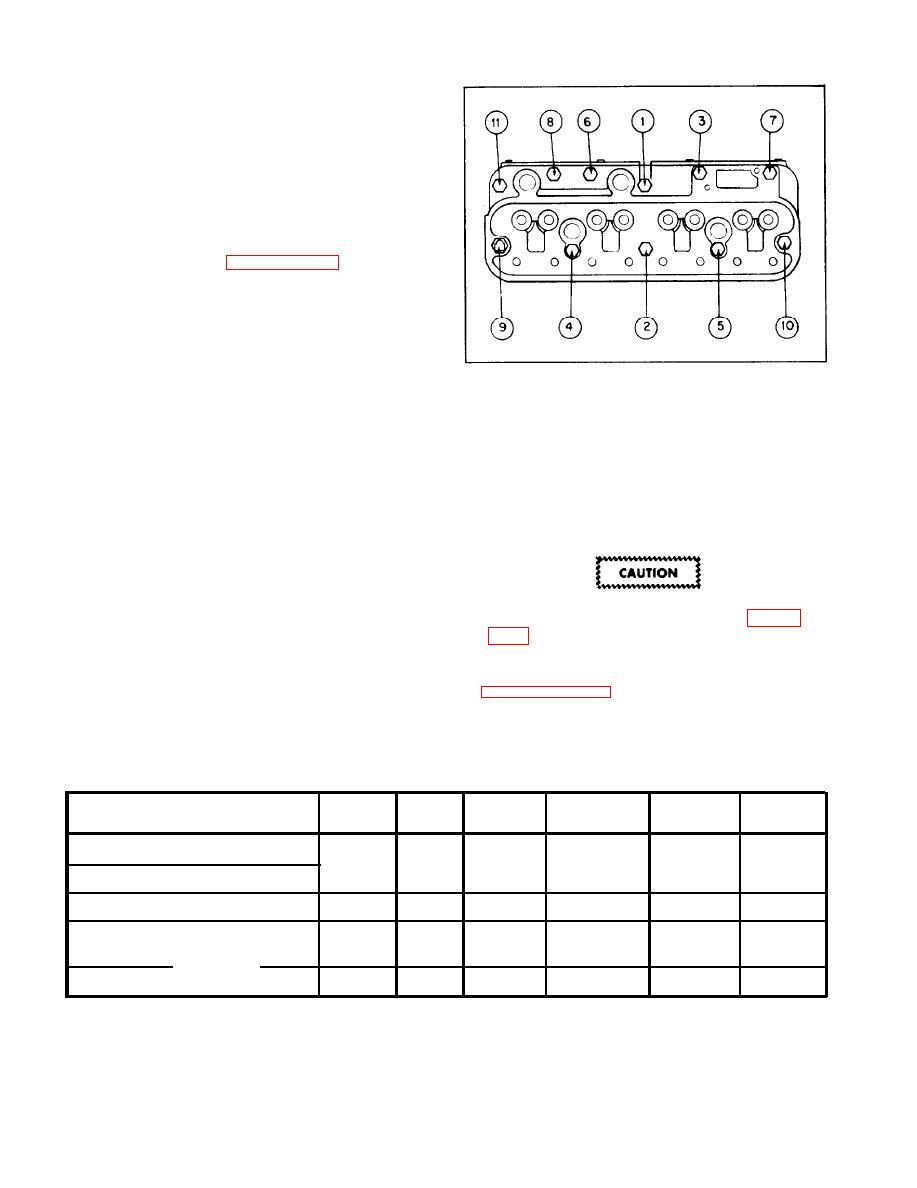

Figure 4-40. Cylinder Head Torque Check Sequence

engine performance. Engine tune-up must be

accomplished semi-annually and more frequently if

engine performance indicates the need for these

4-38. CYLINDER HEAD FASTENERS TORQUE

services. Perform engine tune-up as outlined in the

CHECK. Remove valve rocker arm cover from

following paragraphs after checking the following

cylinder head and check all fasteners for correct

items:

torque. Refer to table in the preceeding paragraph

for proper torque values. Check cylinder head

a. Air Cleaner: be sure air cleaner has received

gasket for leakage.

proper service. Air cleaner must be installed before

making engine tune-up.

b. Fuel Pump: be sure the fuel pump bowl and

strainer has been properly serviced and the fuel

The sequence listed in illustration (Figure

pump is operating satisfactorily.

or nuts must be tightened evenly and

c. Torque Values for Threaded Fasteners:

torqued in accordance with limits listed in

Engines have many studs, bolts, screws, and nuts of

special material and varying sizes and it is very

important to see that all such fasteners are torqued

Check intake and exhaust manifold fasteners for

to the proper values in order that the engine will be

p r o p e r torque and check for evidence of gasket

r e s t o r e d to its original efficiency. Refer to the

leakage .

chart below for torque ratings of various fasteners.

9/16

Size (Diameter)

5/16

7/16

5/6

1/2

3/3

APPLICATION

130-140

145-155

100-l10

70-85

35-40

Cylinder Head

50-60

60-70

50-60

40-50

Manifold

5-20

25-30

Gear Covers, Pumps,

80-90

15-20

50-55

Front and Rear End Plates

25-30

12-16

12-16

Oil Pans

NOTE: All above values expressed in foot-pounds torque.

4-30

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |