|

|||

|

|

|||

|

Page Title:

FAN AND ALTERNATOR BELT ADJUSTMENT |

|

||

| ||||||||||

|

|

If on the other hand it is obvious

9.

that the viscous fan clutch did not engage

and increase the fan speed, the clutch can

be considered defective due to "low fan

speed at operating temperature".

F i n a l l y , a movement of the fan

h.

blade in excess of l/4", exclusive of

fan blade deflection, usually means a

mechanical failure.

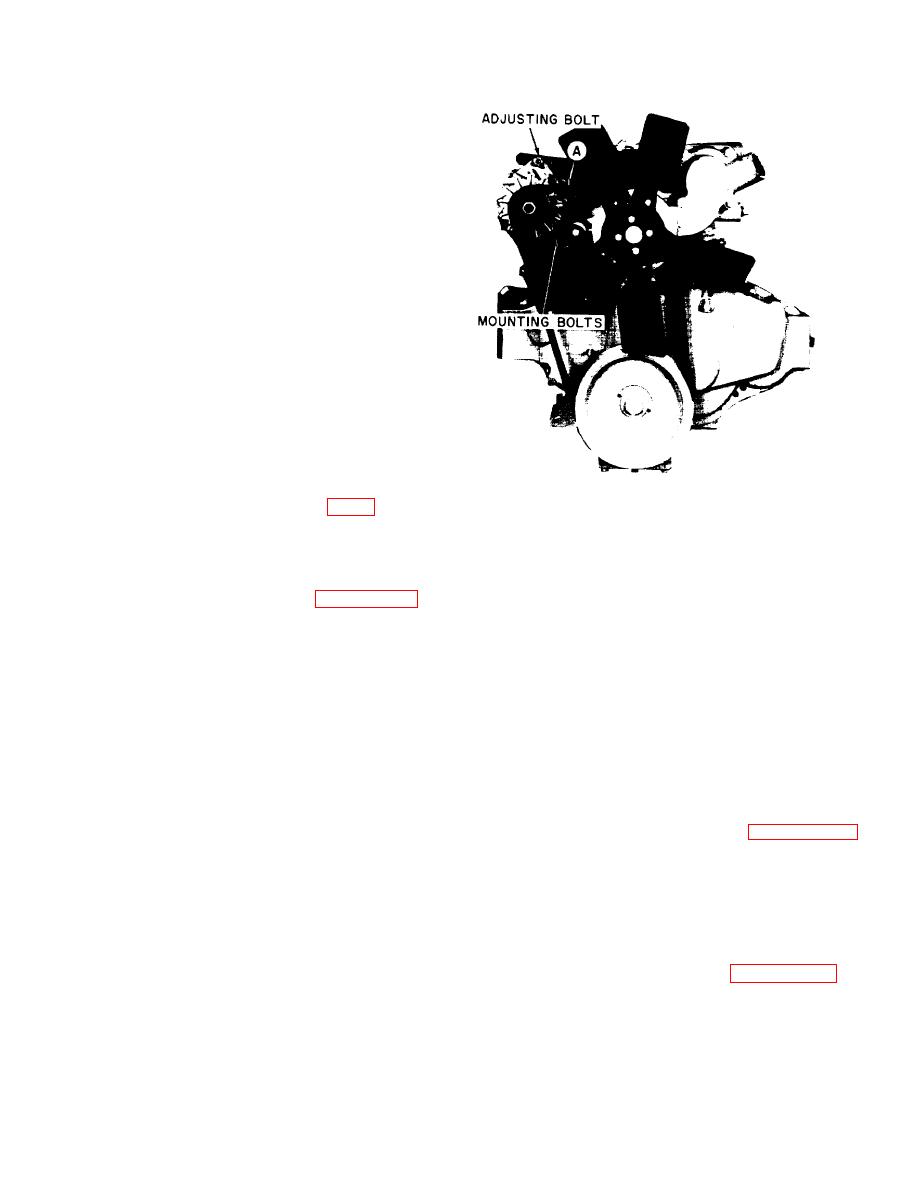

4-15A. FAN AND ALTERNATOR BELT ADJUSTMENT.

The adjustment of the alternator drive

belt should be checked periodically and

if found to be excessively

adjusted

Too tight adjusted

tight or loose.

belts cause early bearing failure in

Belts that are too

the alternator.

loose cause engine overheating and

low battery charge.

Check belt tension by applying

finger pressure (approximately 25 lbs.

Figure 4-29. Alternator Belt Adjustment

f o r c e ) t o p o i n t "A" shown in figure

The belt should deflect l/2 to

4-19.

3/4 inch under the pressure.

4-16.

BRAKE SYSTEM MAINTENANCE

Loosen the adjusting bolt and the

b.

4-17.

PEDAL CHECK AND FREE TRAVEL

two mounting bolts shown in figure 4-29.

ADJUSTMENT.

The following checks

should be made at each 50-hour maint-

Move alternator away from engine

C.

enance interval and appropriate ad-

to tighten the belt, or toward engine

justments made when necessary.

When correct

to loosen belt tension.

tension is obtained by the method des-

a.

Depress each pedal (brake and

cribed in step a., tighten the adjust-

inching) and hold under pressure for

ing bolt (4 foot/pounds) and the

at least ten seconds.

Pedal must be

mounting bolts (7 foot/pounds).

solid, not spongy feeling, and no

drift or leak-down should be evident.

CAUTION

b.

Hold a ruler against the floor

When tightening belt tension, apply

board so that the pedal released height

pressure against the stator laminations

can be measured as shown in figure 4-30.

between the end frames and not against

either end frame.

When adjusting for

C.

Push pedal down by hand until

deflection, pull alternator by hand.

resistance is felt in the master cyl-

Exercise caution

Do not use a pry bar.

inder.

This initial travel should be

when adjusting belts.

Belts adjusted

no more or less than l/8 inch.

too loose will result in belt wear and

high engine temperature due to belt

d.

Adjust free travel by means of

slippage.

the push rod nut shown in figure 4-30.

4-20

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |