|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

D. INSPECTION

1. When the pump is removed, examine the drive

gear carefully for wear, inspecting the gear on

the camshaft at the same time. If scored or

worn badly, both the camshaft and the gear on

the pump must be replaced.

2. Examine the pick-u p screen for clogging or

damage.

3. Remove the cover, being careful not to damage

the lead gasket which acts as a spacer as well

as a gasket to seal the joint.

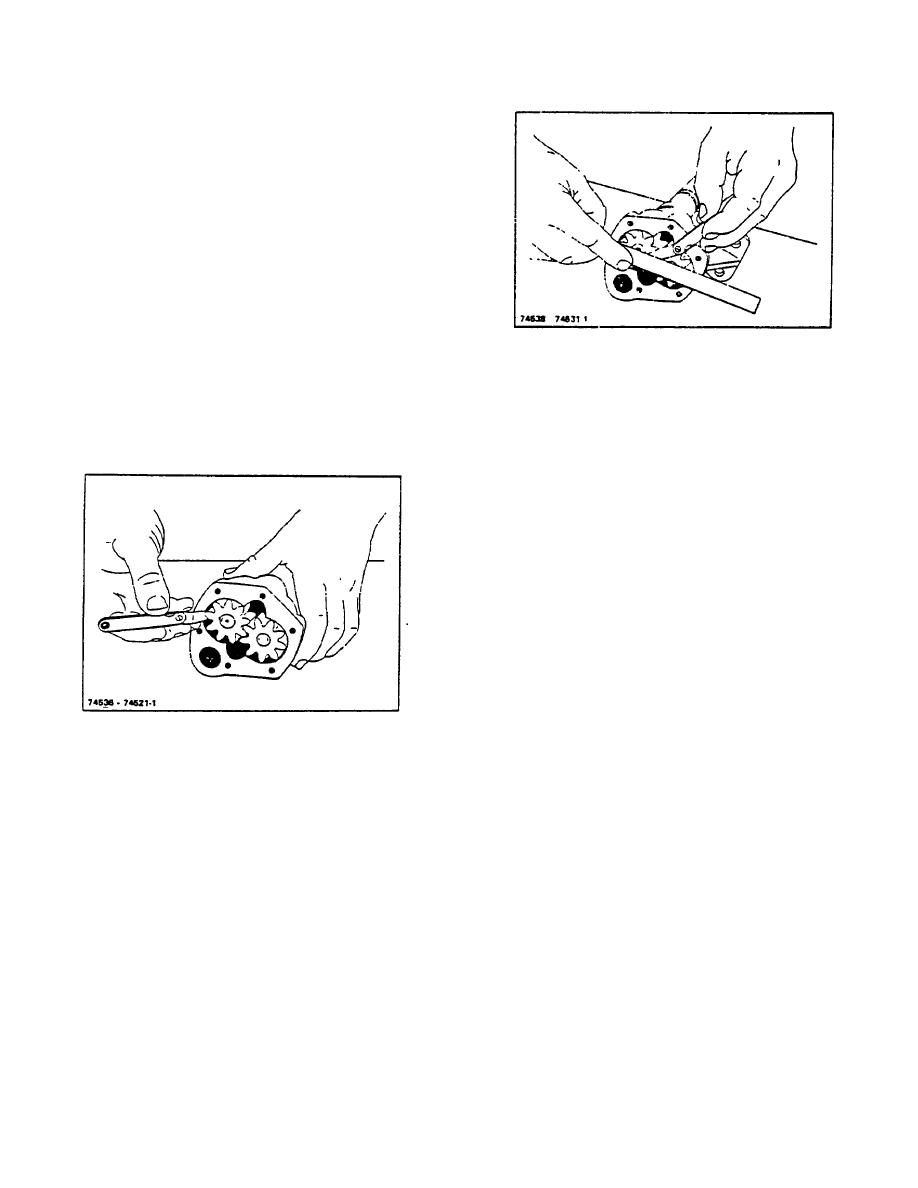

Figure 12-4. Checking Oil Pump End Clearance

4. Examine the gears and pump body for any sign

of wear indicating lack of clearance. The gears

E. ASSEMBLY

should have from .001" to .003" clearance in the

chamber and should make no contact with the

Press drive gear on its shaft and install shaft in pump

walls (Figure 12-3).

body. Secure with snap ring. Press spiral gear back on

end of drive shaft and replace retainer pin. Replace idler

gear, if it was removed, and install oil pump cover and

gasket. Install spacer, frame and screen.

F. INSTALLATION

1. Re-install oil pump assembly on center main

bearing cap. Carefully manipulate the pump

assembly to allow the spiral gear to mesh with

the camshaft mating gear, and with the bushing

connecting to the distributor drive. Make sure

the oil pump assembly is properly seated on the

center, main bearing cap, and secure with

lockwasher and nut.

2. Install oil pan with new oil pan gaskets. Secure

oil pan with attaching capscrews and make sure

Figure 12-3. Checking Oil Pump Gear Clearance in

drain plug is installed.

Pump Body

3. Install engine in truck (refer to TOPIC 17.

5. Inspect the cover and face of the gears for

ENGINE REMOVAL/INSTALLATION.

excessive wear or scoring. With the gasket

assembled to the body there should be .0015" to

4. Upon complete re-assembly, ensure that proper

.006" clearance between the gears and the

weight and quantity of oil have been soured into

cover (Figure 12-4).

crankcase, refer to Maintenance Module

LUBRICANT AND FUEL SPECIFICATIONS

6. Worn or scored gears can be replaced, as can a

worn cover. If the body shows wear in the

5. Start engine, check for oil leaks.

chamber, it can be replaced; but, in a case like

this, a new pump would be the most economical.

6. Refer to TOPIC 13. OIL PRESSURE RELIEF

VALVE ADJUSTMENT to verify proper oil

7. Engine oil pressure must be maintained to

pressure setting.

specification for satisfactory engine life.

7. Turn engine off.

R-104-1

3-44

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |