|

|||

|

|

|||

|

Page Title:

TOPIC 13. OIL PRESSURE RELIEF VALVE |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

TOPIC 13. OIL PRESSURE RELIEF VALVE

A. DESCRIPTION

gauge and its connections before going any

farther.

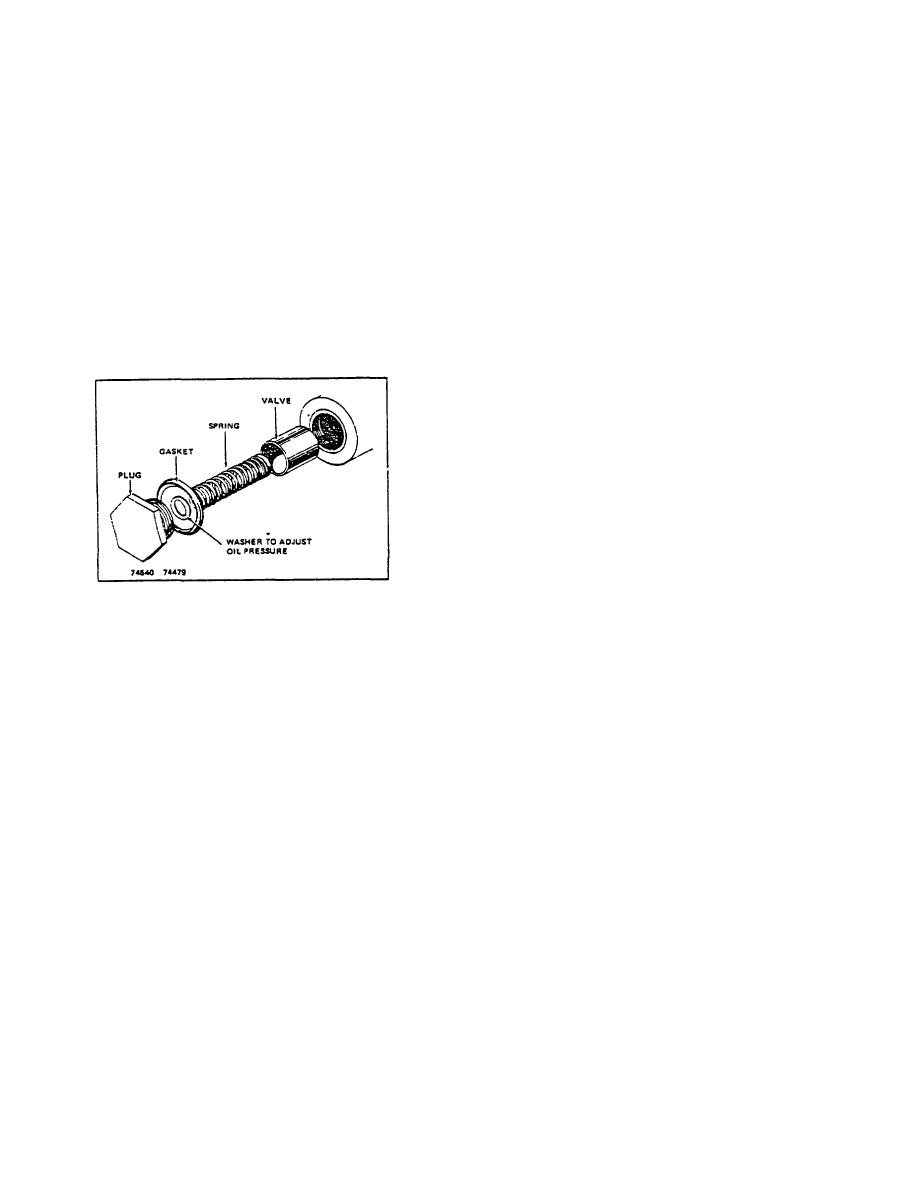

Stabilized lubricating oil pressure is maintained within

the engine at all speeds, regardless of oil temperature,

4. A common source of low oil pressure is clogging

by means of the oil pressure relief valve. This valve is

of the oil pump intake screen with sludge and

located on the left side of the engine, directly below the

carbon. Remove such deposits with a solvent.

carburetor (Figure 11-1). The valve assembly consists

of a plunger, compression spring, adjusting washer or

5. Unusual looseness, grooving, or damage to the

washers, copper gasket, and a plug screwed on the

camshaft bearings or oil pump will also cause

crankcase valve opening (Figure 13-1).

When oil

low oil pressure.

Such conditions call for

pressure at the valve exceeds the 30-40 P.S.I. limit, the

replacement of worn parts.

plunger is lifted off its seat, and oil from the main gallery

is by-passed to the engine oil pan.

D. INSPECTION

Clean oil pressure relief valve parts with a solvent and

dry with compressed air. Replace the spring if it is worn,

bent out of shape, cracked, or weak. Replace cooper

gasket to form an oil tight seal.

E. ADJUSTMENT

The only adjustment variation is, either to install a new

compression spring, or to assemble or remove washers

from behind the existing spring. Up to four washers can

be assembled.

Whenever a relief valve adjustment is necessary, it

should be done AFTER the engine and oil have reached

normal operating temperatures. It is equally important

Figure 13-1. Oil Pressure Relief Valve Assembly

that all other factors such as grade and condition of oil,

bearing clearances, and security of line connections be

B. REMOVAL

satisfactory before any adjustment is attempted.

Proceed as follows:

Under normal conditions, the valve requires very little

attention. However, if the lubricating system has been

1. Allow engine to run until oil reaches normal

allowed to sludge up, the regulator valve may not work

operating temperature.

freely, thereby remaining open or closed. Whenever the

lubricating oil puma is removed for repairs or inspection,

2. Check oil pressure at oil pressure gauge on

the regulator valve should also be disassembled,

instrument panel; verify adjustment using

thoroughly cleaned, and parts inspected.

calibrated oil pressure gauge.

C. DISASSEMBLY

a. Recommended pressure with engine hot

at an idle is 5 to 10 P.S.I.

If, with the proper grade of oil, and the engine warmed

up and running at normal governed speed, and after

b. Recommended pressure with engine hot

adjusting the relief valve the oil pressure is unusually

at full throttle is 30 to 40 P.S.I.

high or low, the following corrective measures should be

tried:

3. To increase pressure, assemble washers one by

one. If after assembling four washers pressure

1. Remove and clean relief valve parts of dirt,

is still low, replace compression spring.

sludge, or carbon.

4. To decrease pressure remove the existing

2. Check oil temperature and condition of oil.

washers, one by one. If pressure is still high,

replace compression spring.

3. If both the relief valve and oil are in good

condition, be sure to check the oil pressure

5. After adjustment is completed, install a new

copper gasket, install and tighten plug.

R-104-1

3-45

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |