|

|||

|

|

|||

|

Page Title:

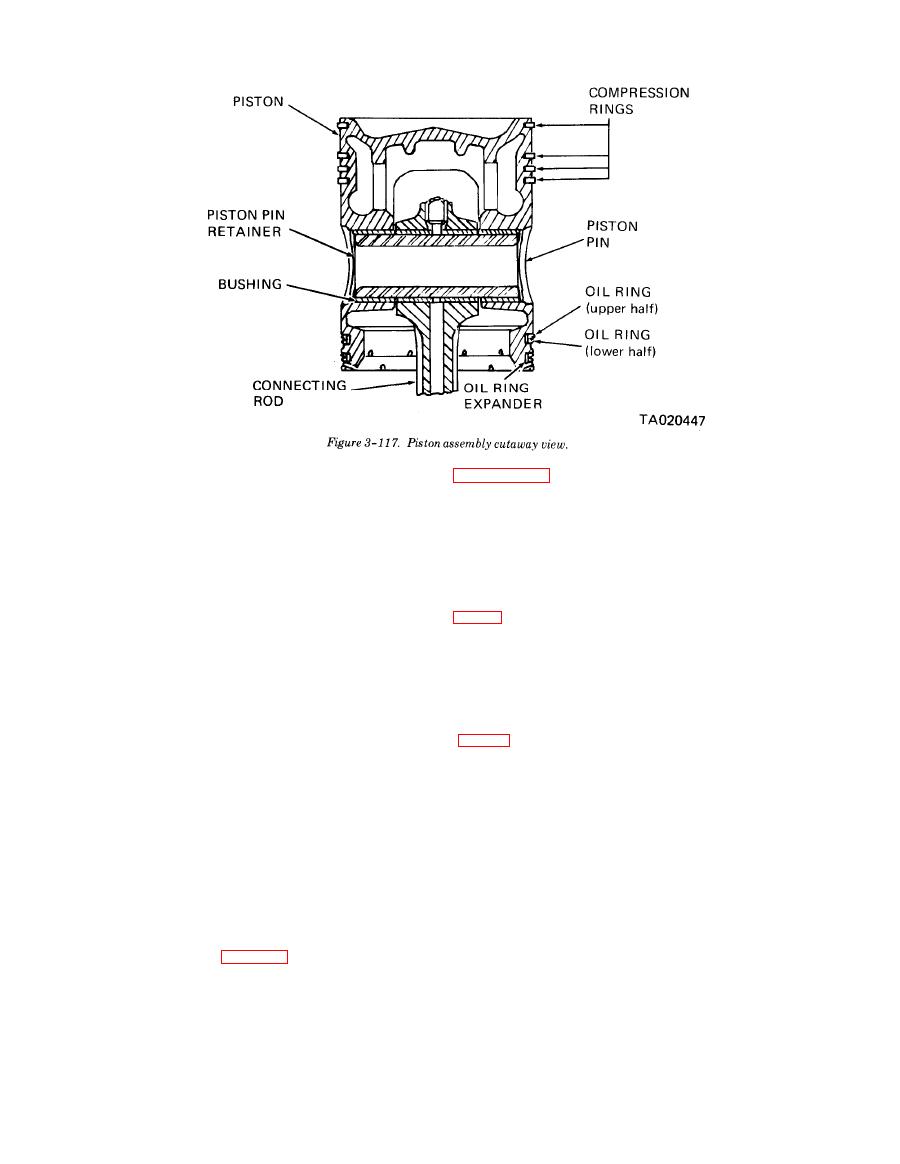

Figure 3-117. Piston assembly cutaway view |

|

||

| ||||||||||

|

|

TM 10-3930-634-34

(c) Insert the unthreaded end of the shaft

notch in bearing.

through the pilot and block bore until it snaps into the

(e) Install the installer/pilot, large diameter

remover.

first, over the shaft and into rear bore of block.

(d) Drive the end bearing from the cylinder

block by using a mallet on the-threaded end-of the

(f) Install short spacer tool, a thrust-washer,

flat washer, and hex nut over threaded end of shaft.

shaft.

(e) Remove the next intermediate bearing in the

(g) Aline the shaft so a C-washer can be inserted

in groove adjacent to installer as shown (A, fig.

same manner.

(f) Remove the opposite end bearing and inter-

(h) Place a C-washer in groove at end of shaft.

mediate bearing in the same manner, working from

(i) Position installer and bearing with notch in

the opposite end of the block and inserting the large

position noted at removal, and using a suitable wrench

diameter of the pilot into the block bore.

on the hex nut, draw the bearing into place until the

(9) Camshaft bearings must be installed in the

end C-washer is up against the installer/pilot,

following sequence: 1) the rear intermediate and rear

(11) Install rear end bearing as follows: (B, fig.

end bearings, in that order, by pressing from the rear

to the front of the block; 2) the front intermediate and

(a) Insert large diameter of pilot in front bear-

front end bearings, in that order, by pressing from the

ing bore of block.

front to the rear of the block. To facilitate assembly,

(b) Insert the support ring in the rear bearing

bearings are color coded on the ends; brown for end

bore.

bearings and orange for intermediate bearings.

(c) Install the shaft, unthreaded end first,

CAUTION

through the pilot and the support.

All replacement bearings must be installed

(d) Position new end bearing on installer/pilot

with the notch located at the same position in

and install the installer/pilot over the end of shaft as

bore as noted prior to removal of original

shown.

bearings.

(e) Place a C-washer in end groove of shaft, and

(10) Install real intermediate bearings as follows:

install short spacer tool, thrust washer, flat washer,

(a) Insert large diameter of pilot in front

and nut on threaded end of shaft.

earing bore of block (A, fig. 3-123).

(f) Aline notch in bearing with locator pin in-

(b) Insert new intermediate bearing through the

staller/pilot and position, as noted at removal, against

rear bore and position against intermediate bearing

end of bearing bore. Draw bearing into place in block

support with notch facing rear of block.

by using a wrench on the hex nut. End bearing is in

(c) Insert unthreaded end of shaft through the

proper position when shoulder on installer/pilot is

pilot and push through entire block bore.

against machined face of block.

(d) Slide the installer on the shaft as shown in

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |