|

|||

|

|

|||

|

Page Title:

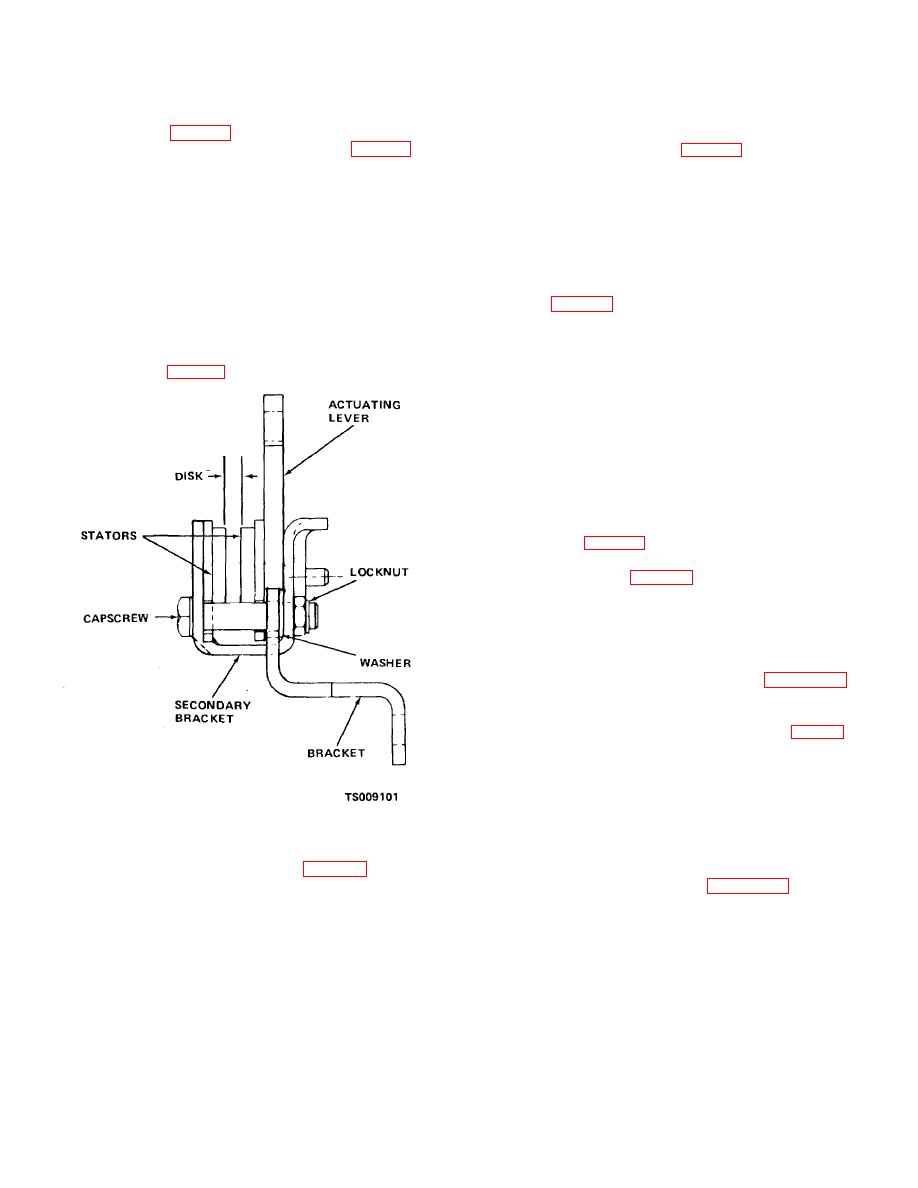

Figure 4-17. Checking brake caliper adjustment. |

|

||

| ||||||||||

|

|

TM 10-3930-631-12

(5) Distance should be 4.50 to 4.74 inches.

position. Make certain stator pads contact disk.

(6) Remove self-locking nut, washer and

f. Brake Switch Adjustment. When the seat is

shoulder screw (fig. 4-15) to disconnect lower linkage.

occupied the seat switch must be closed to allow truck to

Loosen jam nut and adjust spring retainer (fig. 4-15) to

operate. A switch actuator (fig. 4-14) connected to the

compress spring to distance shown in (5) above.

switch linkage moves up and down to operate the switch.

Tighten jam nut to hold retainer.

Adjust actuator as follows:

(7) Thread clevis fully on bottom of rod and

(1)

With operator's seat unoccupied,

secure with jam nut.

actuator must move down and depress switch arm and

(8) Connect lower clevis to brake caliper

open switch contacts.

with shoulder screw, flat washer and lock nut.

(2) Check across switch with continuity

e. Caliper Assembly Brake Pad Inspection and

tester to make certain switch contacts are open.

Adjustment. If caliper brake pads wear or are out of

(3) If contacts are not open, adjust switch

adjustment, adjust as follows:

bracket (fig. 4-16) by loosening mounting screws and

(1) Seat must be occupied and brake in off

raising or lowering switch until switch arm contacts

position.

actuator properly. Further adjustment is possible by

(2) Check distance between disk and pads

moving jam nuts on brake rod to raise or lower switch

on brake stator (fig. 4-17).

actuator to achieve correct switch operation. Tighten

bracket mounting screws and jam nuts to hold

adjustment.

(4) With seat occupied, switch arm should

move away from switch as actuator rises. Check switch

with continuity tester, to be certain switch contacts are

closed.

g. Adjustment Check. Check adjustment as

follows:

(1) Connect battery receptacle and prepare

truck to travel (para 2-4).

(2) With operator in seat and key switch on,

place truck in motion (para 2-7).

(3) Remove weight from seat to apply

parking brake. Truck should stop and remain stationery

on a 15 degree incline.

(4) Install drip pan, floor and toe plates and

sheet metal cover.

h. Switch Replacement. Refer to figure 4-14 to

replace seat switch.

4-32. Service Brake Linkage

a. General. The service brake pedal (fig. 2-1) is

connected to the master cylinder by a clevis attached to

the cylinder piston push rod. A spring, mounted between

two retainers on the rod, returns the pedal to released

position.

b. Adjustment. Pedal free play should be adjusted

to one-half inch of travel to allow master cylinder to

Figure 4-17. Checking brake caliper adjustment.

return to off position and reduce useable length of stroke.

Remove floor and toe plates to gain access to master

(3) Tighten lock nuts (fig. 4-17) to more

cylinder and linkage. Refer to figure 4-18 and adjust

stator pads closer to disk. Tighten nuts until disk almost

service brake pedal travel as follows:

makes contact with stator pads. Disk should move freely

between pads.

(4) Release seat to place brake in park

4-23

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |