|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

CHAPTER 11

STEERING GEAR

11-2. Steering Gear Lash Adjustment

11-1. Description

a. Disconnect pitman arm from pitman shaft on

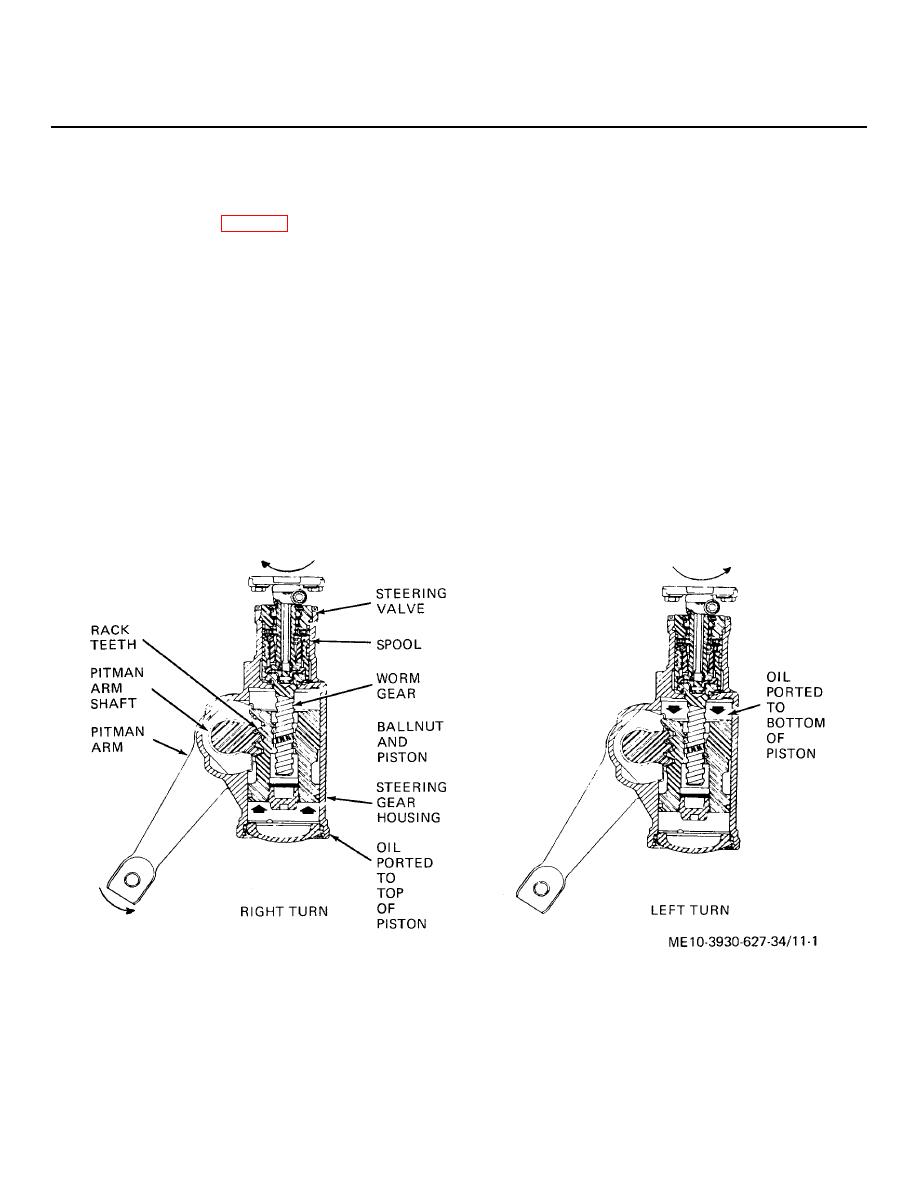

The fork lift trucks are equipped with power steering.

The steering gear has an integral steering valve that

steering gear.

operates as follows:

b. Gently rotate steering wheel until it comes to rest

against stop. Then gently rotate it in opposite direction

steering valve and a combination ball nut and piston

until it rests against opposite stop, carefully counting

which engages the steering gear shaft through balls

turns required to rotate from stop to stop. Divide this

which mesh with the worm gear on the end of the shaft.

number by two and rotate steering wheel in opposite

The toothed rack on the piston engages the toothed

direction by resulting number to center steering wheel.

gear segment on the pitman arm shaft. As the steering

Mark bottom of wheel with tape.

wheel and steering gear shaft are rotated, the force of

c. Remove the horn button from the steering gear

the worm gear teeth against the balls causes the

hub.

steering gear shaft to shift axially (up or down,

d. Turn the steering gear 1/2 turn off center. Use a 24

depending on direction of turn) a slight amount.

inch-pound torque wrench in the steering wheel nut to

b. This axial shift operates the hydraulic steering

determine the torque required to rotate the steering

valve by shifting a spool up or down and causes oil

shaft slowly through a 20 degree arc.

under pressure from a section of the hydraulic pump to

e. Turn the steering gear back to center. Loosen nut

be ported to the top or bottom of the piston.

on lash adjuster opposite pitman shaft extension and

c. This

hydraulically

operated

movement

is

rotate adjuster until torque reading is 6 inch-pounds

transferred to the bellcrank on the steering axle to steer

greater than that determined in d. above. Retighten lock

the vehicle. In this manner, hydraulic power assists

nut to 20 to 30 foot-pounds and recheck torque.

manual power to steer the vehicle.

f. Reconnect pitman arm and replace horn button.

Figure 11-1. Power steering gear operation.

11-1

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |