|

|||

|

|

|||

|

Page Title:

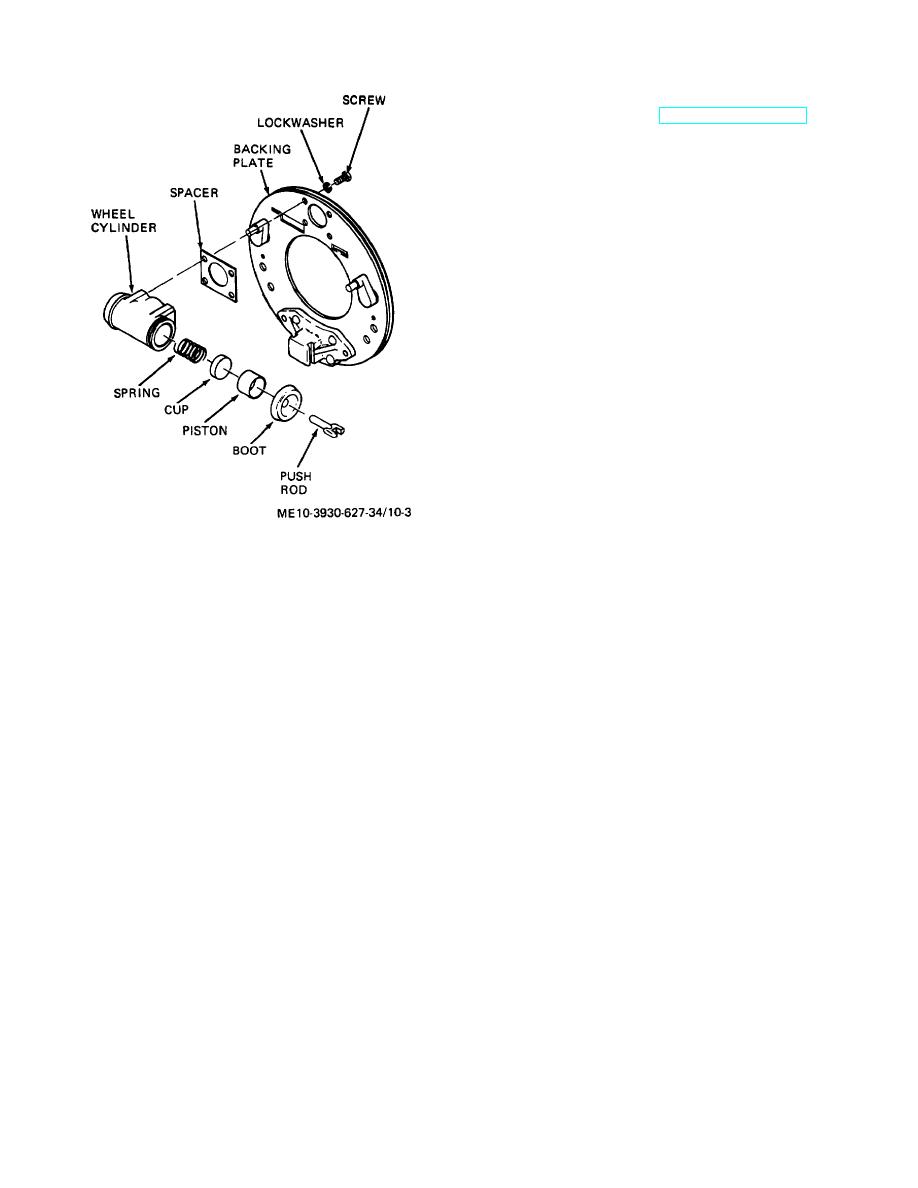

Figure 10-3. Brake wheel cylinder. |

|

||

| ||||||||||

|

|

10-5.

Brake Drum Repair

a. Remove brake drum, TM 10-3930-627-12, and with

a shop brake drum gage, inside micrometer or dial

indicator check the friction surfaces of the drum for:

(1) Taper, or bell mouthed condition over 0.010

inch TIR (total indicator reading).

(2) Out-of-round over 0.010 TIR.

(3) Oversize beyond 11.500 inches.

b. If any defect listed is found, correct the condition

by truing the braking surface in a brake drum lathe.

Enlarge drum bore in 0.020 inch steps as standard

oversizes. If drum must be cut out beyond 0.060

oversize to remove defects, replace drum.

c. Stamp drum with actual oversize and tag it so it will

be used only with oversize brake lining or shimmed

brake shoes.

Figure 10-3. Brake wheel cylinder.

10-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |