|

|||

|

|

|||

|

Page Title:

Transmission Gear Case Assembly |

|

||

| ||||||||||

|

|

e. Installation. Install in reverse order of

(10) Inspect pistons for flat spots, scoring and

wear. Smooth minor surface damage with a soft

removal. Refer to paragraph 2-9.

hone or crocus cloth. Replace pistons if damage or

4-3. Transmission Gear Case Assembly

wear is excessive.

a. Removal. Remove the transmission from the

(11) Inspect the cylinders for nicks, chips,

truck. Refer to paragraph 2-9.

scratches, scoring and other damage and wear.

b. Disassembly.

Repair cylinders if possible or replace as required.

(1) Remove the control valve from the

(12) Inspect the turbine shaft for cracks and

transmission housing. Refer to paragraph 4-4.

distortion and for damage to the splined end.

(2) Lay the transmission on the gear case.

Replace the turbine shaft if damaged.

Remove the capscrews which secure the torque

(13) Inspect bearings for nicks, chips, flat

converter housing to the gear case. Attach a hoist to

spots. scoring, wear, and out-of-round condition.

the housing and remove the housing and the disc

Replace bearings if any damage is evident.

drum assembly as a unit. Be careful not to damage

(14) Inspect the discs for wear, scoring, dents,

seal rings in the collector ring on the gear case.

cracks, chips and other damage. Replace if damage

(3) Refer to figure 4-5. Remove the capscrews

is evident or if grooves are worn out of clutch

(1) and lockwashers (2) which secure the retainer

facing.

(3) to the housing. Remove the retainer (3) and

(15) Inspect piston rings for free fit in their

gasket (4).

grooves.

(16) Inspect the drum for cracks, chips, nicks,

scratches and other damage. Repair or replace as

required.

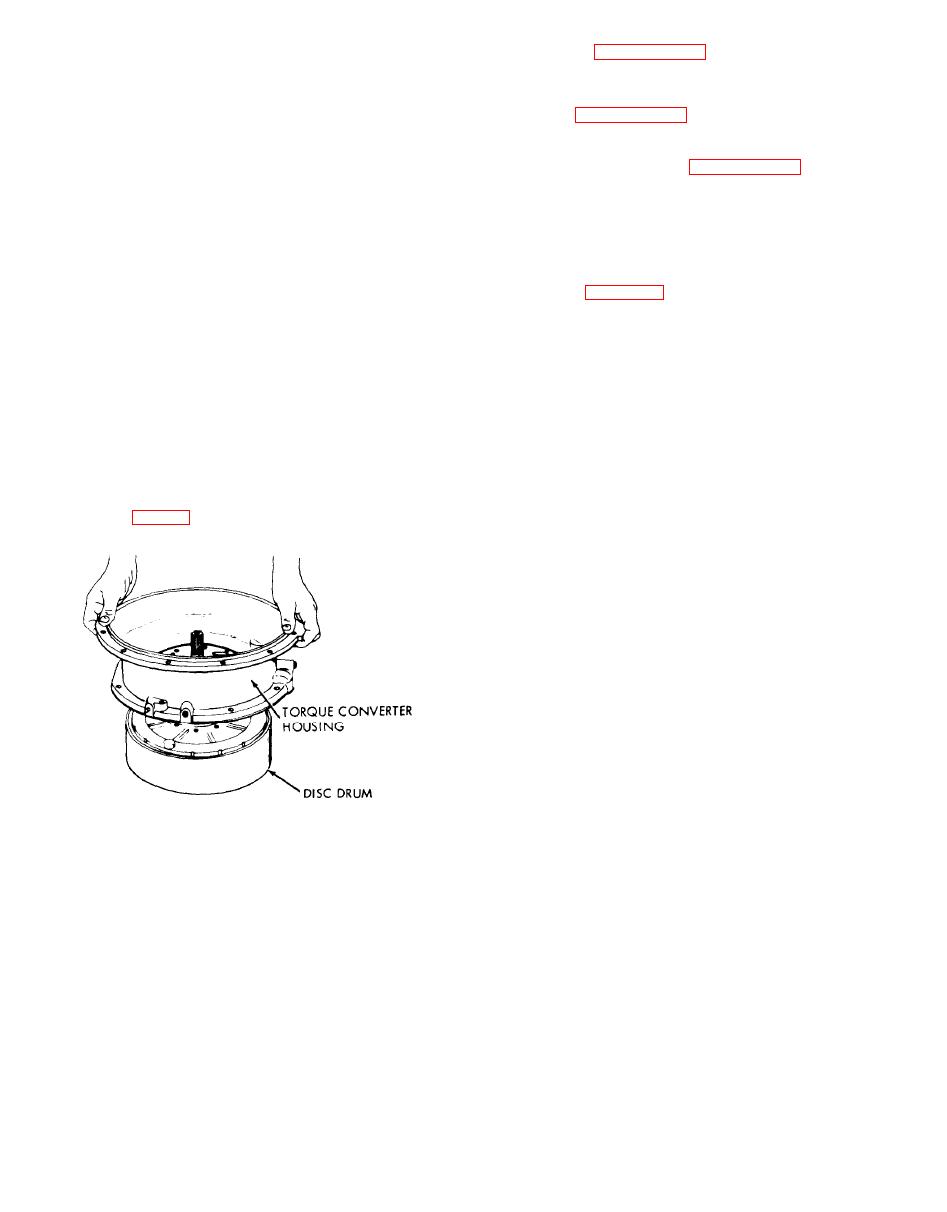

d. Reassembly. Lubricate all parts with trans-

mission lubricant. Assemble the drum and disc

assembly in reverse order of disassembly. Install

torque converter by reversing removal procedure.

Mount drum and disc assembly to torque converter

housing (fig. 4-4 I.

ME 3930-624-34/4-4

Figure 4-4. Installing torque converter to drum and disc assembly.

4-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |