|

|||

|

|

|||

|

Page Title:

INSTALLING PISTON AND ROD-ASSEMBLIES . |

|

||

| ||||||||||

|

|

TM 10-3930-623-34

NOTE

NOTE

Some piston rings have a taper face.

Mate indicator dimple on camshaft

These rings are clearly marked TOP

gear with those on crankshaft gear to

on upper side. Install with this side

insure correct timing of valves to

up.

piston operation.

6-23. INSTALLING PISTON AND ROD-ASSEMBLIES .

2. Install key (11) in camshaft keyway. Assemble

Soak piston assembly with rings in OE-30 engine oil,

cam gear (9) to camshaft by driving or pressing it on. At

drain excess oil, and install assembly in cylinder as

the same time hold the camshaft forward with a suitable

follows:

bar through the fuel pump opening in the block so there

is no possibility of the camshaft bumping the expansion

1. Compress rings into ring grooves with a ring

plug at the rear end. This could force it out of position,

compressor. Do not overtighten.

thus causing an oil leak. Check camshaft end play as

2. Place big end of rod into correct cylinder as

shown in figure 7-1, item 11.

indicated by number stamped on rod big end and cap.

3. Install camshaft gear governor drive assembly

Cylinders are numbered from 1 to 6, beginning at the

with balls on camshaft.

timing gear end of the engine. Orient rod big end to

CAUTION

crankshaft journal so it will meet properly. Rods are

Never use camshaft nut to pull gear

properly oriented when offset side of each rod faces

onto camshaft. This will break

away from the adjacent main bearing, and the numbers

threaded end off of a cast iron

stamped on the rod (1 through 6) face the camshaft.

camshaft and damage threads on a

Press piston into cylinder with end of hammer handle.

steel camshaft.

CAUTION

If a rod is installed reversed, the

4. Install camshaft nut (10). Torque nut to 85-90

engine will lock and the rod will

foot pounds.

probably bend on the first attempt to

5. Assemble governor upper race shaft to end of

crank the engine.

camshaft. Lubricate governor with OE-30 engine oil.

3. Lightly oil, then install connecting rod bearing

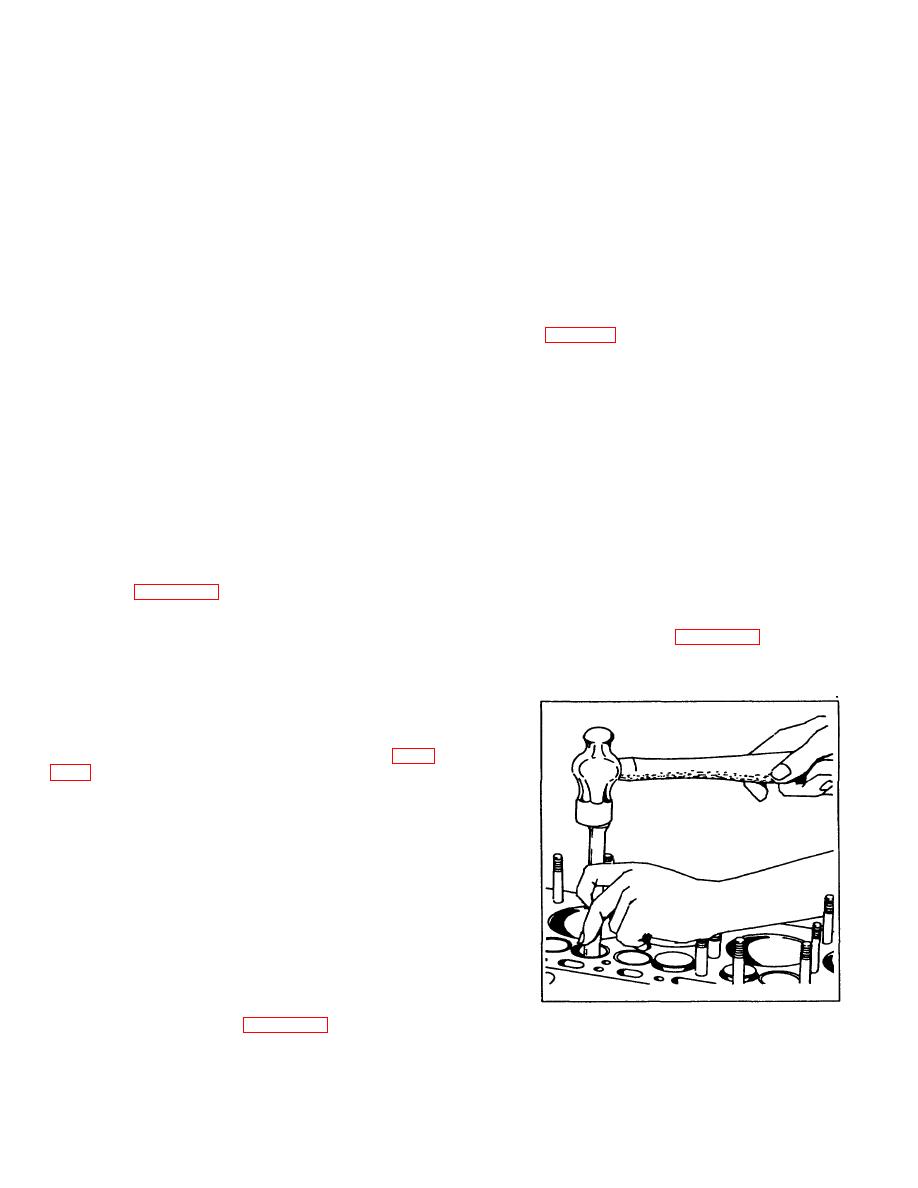

6-26. VALVE GUIDE REPAIRS . Press out excessively

inserts (24, figure 4-28) in connecting rod, position rod

worn or damaged valve guides with arbor press or

on crankshaft secure bearing cap in place. Torque nuts

suitable driver from cylinder head side (see figure 64).

(22) to 40-45 foot pounds, then tighten nuts as

Press new valve guides (4, figure 4-23) into block from

necessary to align slots with cotter pin hole in bolts (21)

top of block. Press until guide is 1-15/32 inch below

and install new cotter pin (19).

cylinder block deck.

4. Turn crankshaft one revolution to be sure

with reassembly.

CAMSHAFT AND CAMSHAFT BEARINGS.

6-24.

Install camshaft bearings (15, 16, 17 and 18, figure

bearing as follows:

1. Align the oil hole in the bearing with the oil

passage in the block which supplies it with lubrication.

2. With a piloted driver, tap each bearing int o

place.

6-25. CAMSHAFT INSTALLATION.

NOTE

When installing camshaft use special

care to prevent camshaft bumping

against and loosening expansion

plug to cause an oil leak.

1. Insert camshaft (19, figure 4-23) into position in

Figure 6-4. Driving Out Valve Guides

block, and install thrust plate (12), washers (14) and

screws (13).

6-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |