|

|||

|

|

|||

|

Page Title:

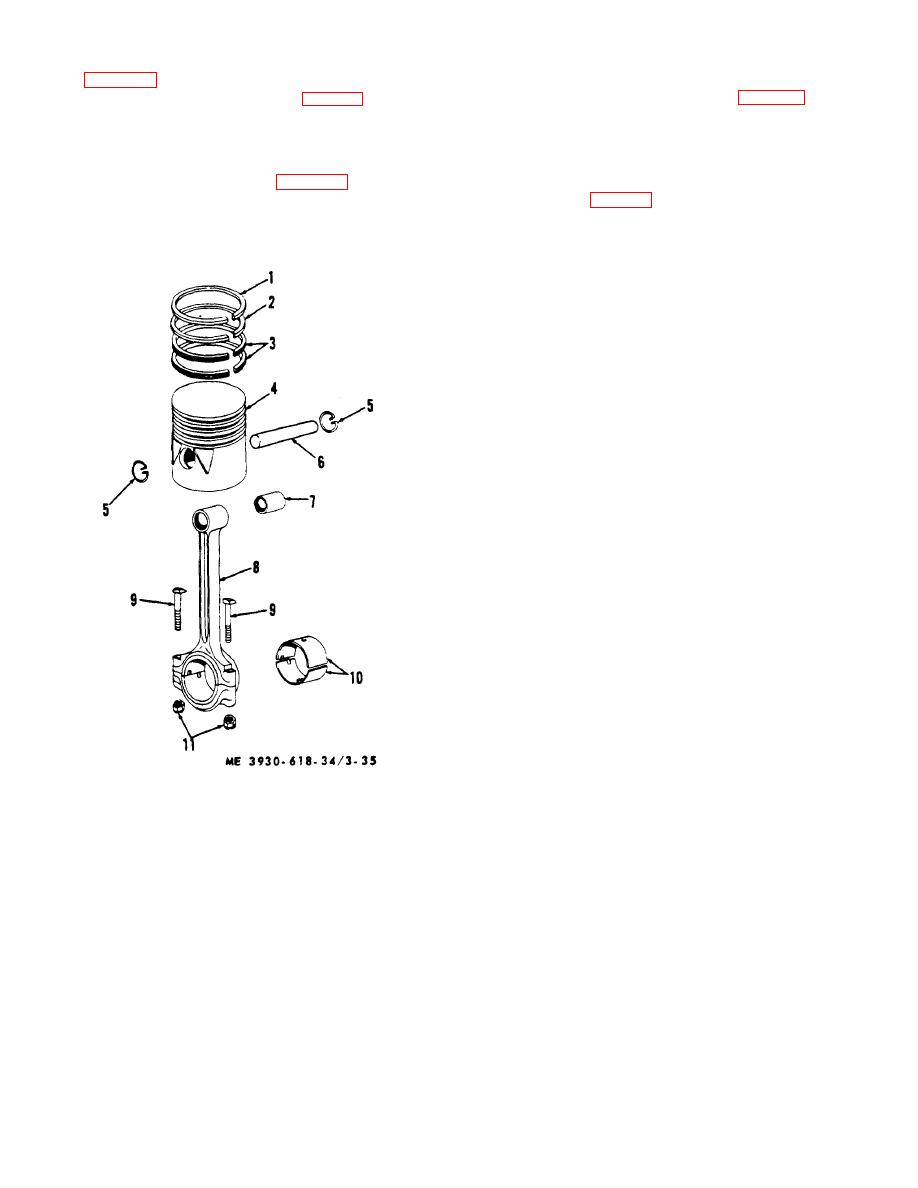

Figure 3-35. Piston and connecting rod. |

|

||

| ||||||||||

|

|

(3) Drain oil from crankcase and remove oil

(6) Inspect, disassemble, and reassemble

pan (para 3-12).

pistons and connecting rods as required.

(4) If cylinder sleeves (2, fig. 3-32) are worn

(7) Inspect crankshaft 14, fig. 3-33) bearing

so there is a ridge at the upper end of ring travel, remove

journals at connecting rod throws for scoring, checking,

ridge with a ridge reamer before piston is removed. This

or signs of overheating. If any of these conditions exist,

prevents damage to rings during removal and

crankshaft will require reconditioning or replacing.

c. Disassembly.

installation.

(5) Remove nuts (11, fig. 3-35) and bearing

(1) Using suitable tool. remove piston pin

cap from each connecting rod (8) in turn and push piston

retainer ring (5, fig. 3-35 ) at each end of piston pin (6).

and connecting rod assembly out through top of cylinder

(2) To avoid breaking piston rings, the use of

block. Reassemble bearing caps on their respective

a ring remover and installer is recommended. Care must

connecting rods as they are removed.

be taken not to over-stress piston rings by spreading

ends more than is necessary to remove them from

piston. Before removing rings, inspect for wear and side

clearance in grooves.

However, removal will be

necessary in order to clean carbon from grooves.

(3) Using a driving tool, drive piston pin (6)

from piston. Use a wooden block or brass drift as a

driver. In some instances it may not be necessary to

drive piston pin from piston.

Specified clearance

between piston and pin at room temperature is 0.0001

inch to 0.0005 inch loose.

d. Piston and Piston Ring Inspection.

(1) As gummy deposits are not always

removed from piston walls and ring grooves with fuel,

these parts may be cleaned with Cleaning Solvent (Spec

P-S-661) and then blown off with dry compressed air.

After cleaning, piston skirt, piston rings, and ring grooves

should be thoroughly inspected.

CAUTION

Some types of solvents contain

chemicals injurious to aluminum

alloy. Do not use a cleaning agent

containing such chemicals.

(2) Piston skirt should be carefully inspected

for score marks or other indications of improper piston

clearance. Any scored pistons should be replaced.

(3) Inspect inside of piston for cracks, any of

which make it unfit for further use. Make certain that

drilled holes in piston walls are open and clean.

(4) Check piston for wear by inserting it into

cylinder sleeve and measuring clearance between piston

and sleeve. Maximum tolerance is from 0.0006 inch

tight to 0.002 inch loose, measured at bottom of piston

1 Top ring

skirt and at right angles to piston pin.

2 Second ring

3 Third and fourth ring

4 Piston

5 Pin retainer

6 Piston pin

7 Bushing

8 Connecting rod

9 Bolt

10 Rod bearing

11 Nut

Figure 3-35. Piston and connecting rod.

3-42

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |