|

|||

|

|

|||

|

Page Title:

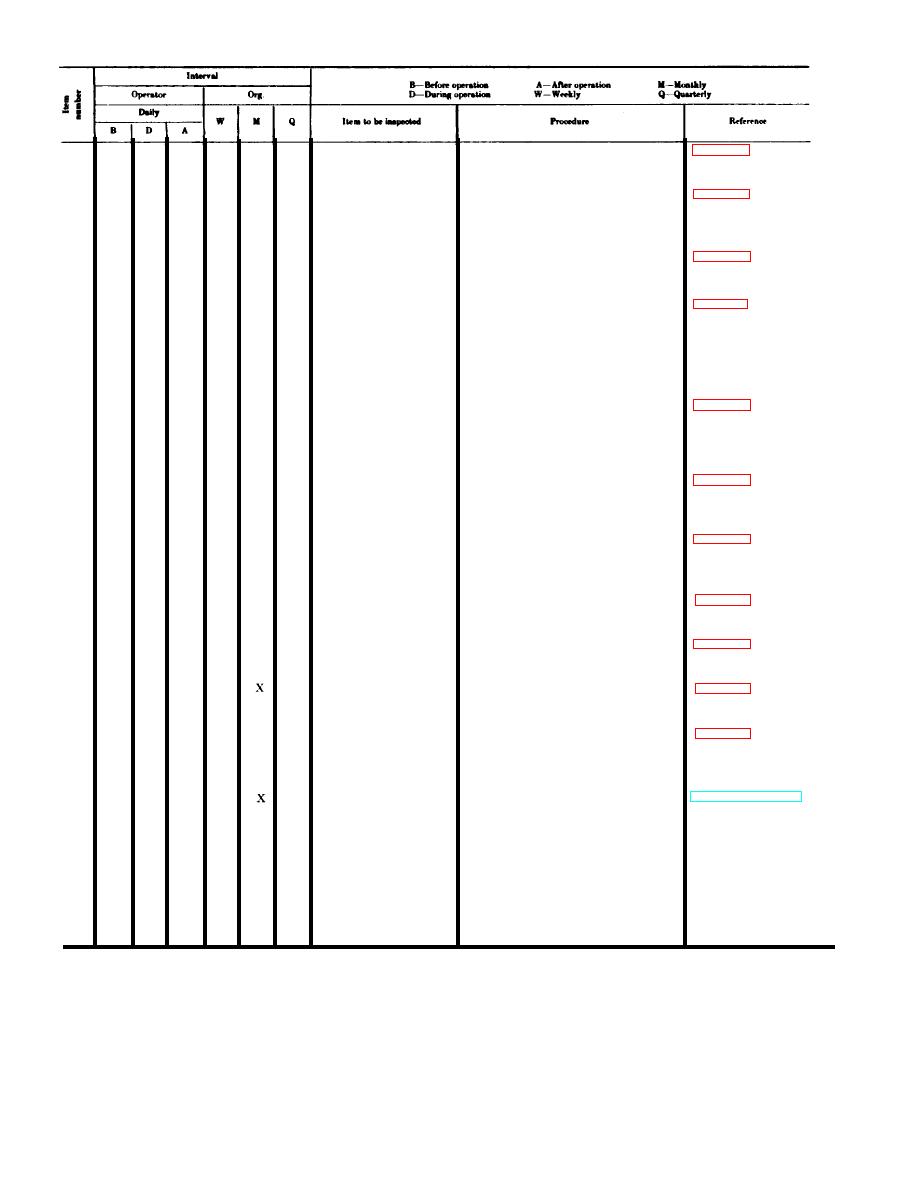

Table 2-1. Preventive Maintenance Checks and Services |

|

||

| ||||||||||

|

|

Table 2-1. Preventive Maintenance Checks and Services (Cont'd)

X

Spark Plugs

Remove, clean and test spark plugs. Adjust

4

gap to 0.025 in. Torque spark plugs 15 to

20 ft-lbs.

Inspect steering axle for insecure mounting.

Steering Axle

X

5

Inspect king pins and center arm for

insecure mounting and wear. Check

wheels to be sure there is 0 toe-in.

Radiator

6

Inspect for insecure mounting, leaks, bent

X

fins, and obstructions. If necessary add

coolant until level is just below filler neck.

X

Breather Lines

7

Crankcase vent hose and vent line from

rocker arm cover may be cleaned with

compressed air. Rocker arm cover valve

may be cleaned with a cleaning solvent.

Fire Extinguisher

8

Inspect for broken seal. Replace extin-

X

guisher if gage does not indicate full

charge.

X

V-Belt and Pulleys

Inspect belt for frayed condition, wear,

9

glazing, and deterioration. Inspect

pulleys for breaks and insecure mounting

Adjust V-belt for inch deflection mid

way between pulleys.

X

10

Hydraulic Fluid Tank

Check level of hydraulic fluid. Refer to

current LO and add fluid as required

Clean or replace the breather filters and

line filters.

Inching and Service Brake

Check service brake pedal for free travel

X

11

Pedals and Linkage

of inch. Inspect for insecure linkage.

Inspect inching pedal and linkage for

improper adjustment.

X

Hand Brake Lever and

Inspect for insecure mounting, improper

12

operation. and maladjustment. Check

Linkage

cable for wear and frayed condition.

X

Tilt Cylinders

Check for leaks and insecure mounting.

13

Adjust for correct degree of tilt of 3 for-

ward and 10 back.

Inspect for burned out lamps and defective

Lights

*14

leads. Replace lamps and leads as neces-

M

sary.

Inspect chains for wear and inspect rollers

X

Lift Chains

15

for breakage and binding. Adjust chain

so that the carriage lifts evenly.

X

Inspect for leaks and insecure mounting.

16

Lift Cylinder

Replace damaged instruments. Tighten TM 10-3930-618-10

17

Controls and Instruments

loose mountings. With engine running,

cheek controls and instruments for im-

proper operation. The normal instrument

readings are:

Ammeter-Indicates slight positive charge

Hourmeter-Register total hours of opera-

tion

Oil pressure gage-25 to 30 psi

Temperature gage-160F. to 180F.

2-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |